A Calibration Method for Conductivity Measurement of Solutions Below 10us/cm

A calibration method and conductivity technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of easy distortion of calibration test data and achieve the effect of improving authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The specific steps of the implementation are: use the Mettler-Toledo FiveEasy conductivity meter as the reference conductivity meter, the temperature of the measured liquid is kept at 25±0.1°C, use nitrogen to protect the measured liquid, and the measured liquid is chlorinated by the reference Potassium reagent is prepared, and all containers used are plastic containers without ion dissolution. The water used to prepare the conductivity measurement solution is high-purity water with a resistivity ≥ 18.0MΩcm.

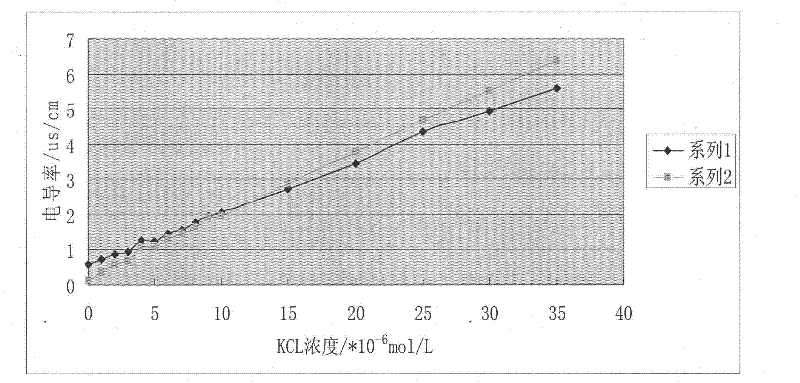

[0014] attached figure 1 The relationship function between conductivity and KCL solution concentration is shown graphically.

[0015] The reference conductivity meter and the conductivity meter measuring equipment simultaneously measure different concentrations of KCL solutions to form a figure 1 curve. figure 1 Among them, series 1 is the conductivity curve measured by the conductivity meter to be calibrated, and series 2 is the conductivity curve measured by t...

Embodiment 2

[0028] According to this embodiment 2: the Mettler-Toledo FiveEasy conductivity meter (supporting electrode is LE740 type) is used as the reference conductivity meter, the temperature of the measured liquid is kept constant at 25 ± 0.1 ° C, and the measured liquid is protected by nitrogen gas. The test solution is prepared from the standard potassium chloride reagent, and all the containers used are plastic containers without ion dissolution. The water used to prepare the conductivity measurement solution is high-purity water with a resistivity ≥ 18.0MΩcm.

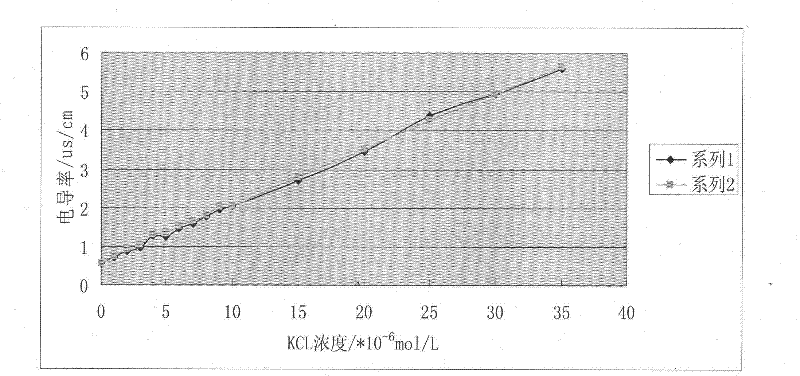

[0029] attached image 3 The relationship function between conductivity and KCL solution concentration is shown graphically. Series 1 is the conductivity curve measured by the reference conductivity meter, series 2 is the conductivity curve measured by the conductivity meter to be calibrated, and series 3 is the conductivity curve measured by the conductivity measuring equipment after calibration.

[0030] According to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap