Oxygen blowing holder

A technology of clamper and oxygen blowing tube, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., which can solve the problems of tempering and burning operators, poor sealing effect, easy leakage and tempering, etc. , to achieve the effect of fast connection speed, good sealing, and not easy to leak and temper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

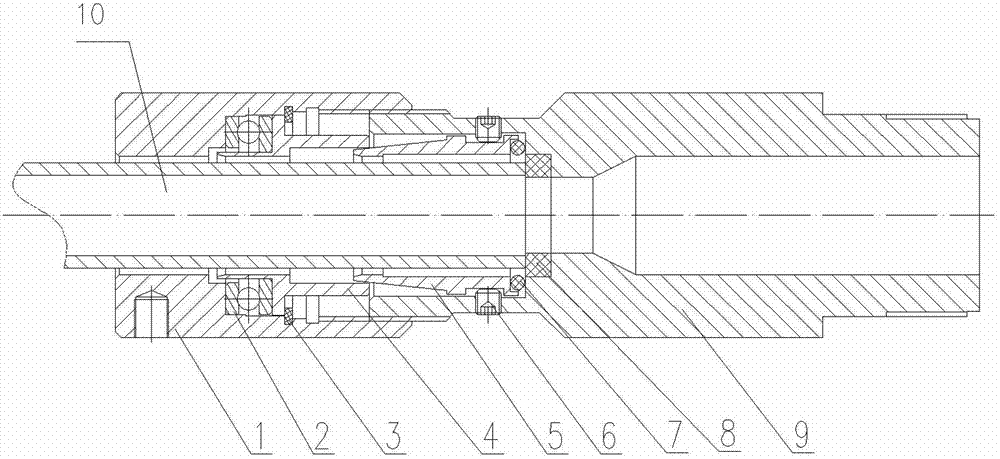

[0013] Such as figure 1 A specific embodiment shown includes a movable sleeve 1 and a fixed sleeve 9, and the movable sleeve 1 and the fixed sleeve 9 are screwed together.

[0014] The movable sleeve 1 is provided with a locking sleeve 4 that is rotatably connected with the movable sleeve 1, and the locking sleeve 4 is provided with a limit boss that protrudes outward. The sleeve hole of the movable sleeve 1 is a stepped hole, and one end of the large aperture is used In connection with the fixed sleeve 9, one end of the large aperture of the locking sleeve 4 is provided with a thrust bearing 2, and the thrust bearing 2 is clamped on the limit boss on the locking sleeve 4 and the inner step surface of the movable sleeve 1, and the locking sleeve The limit boss on 4 is provided with a retaining ring 3 on the side away from the thrust bearing 2, and the retaining ring 3 is fixed on the movable sleeve 1. So that the locking sleeve 4 can rotate in the movable sleeve 1 but cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com