Air spring with function of regulating dynamic rigidity according to adaptive pressure and buffering step pressure

An air spring, self-adaptive technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of non-continuous adjustment of stiffness, achieve smooth and continuous adjustment, reasonable and controllable adjustment stiffness characteristic curve , the effect of improving the dynamic stiffness adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

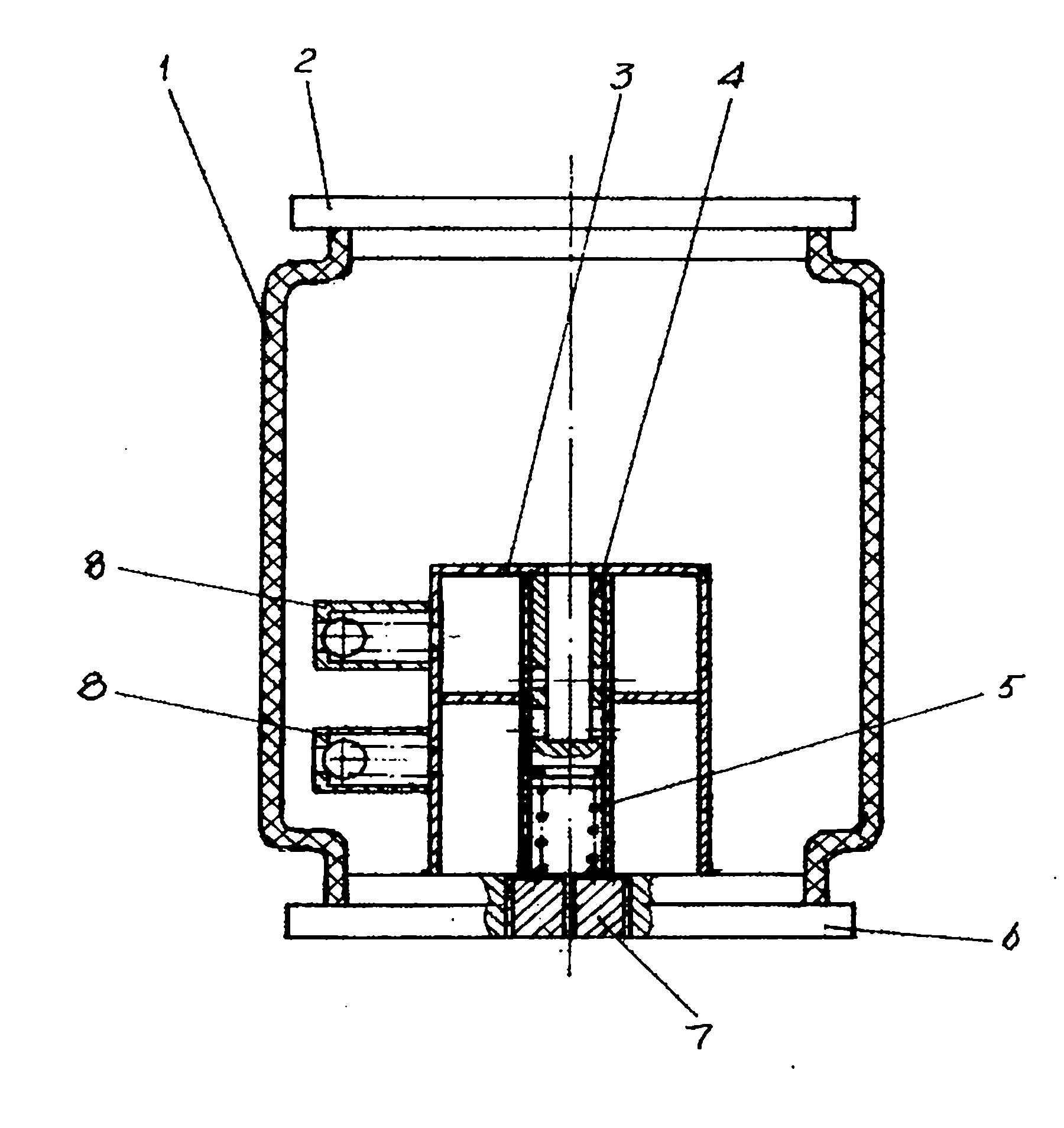

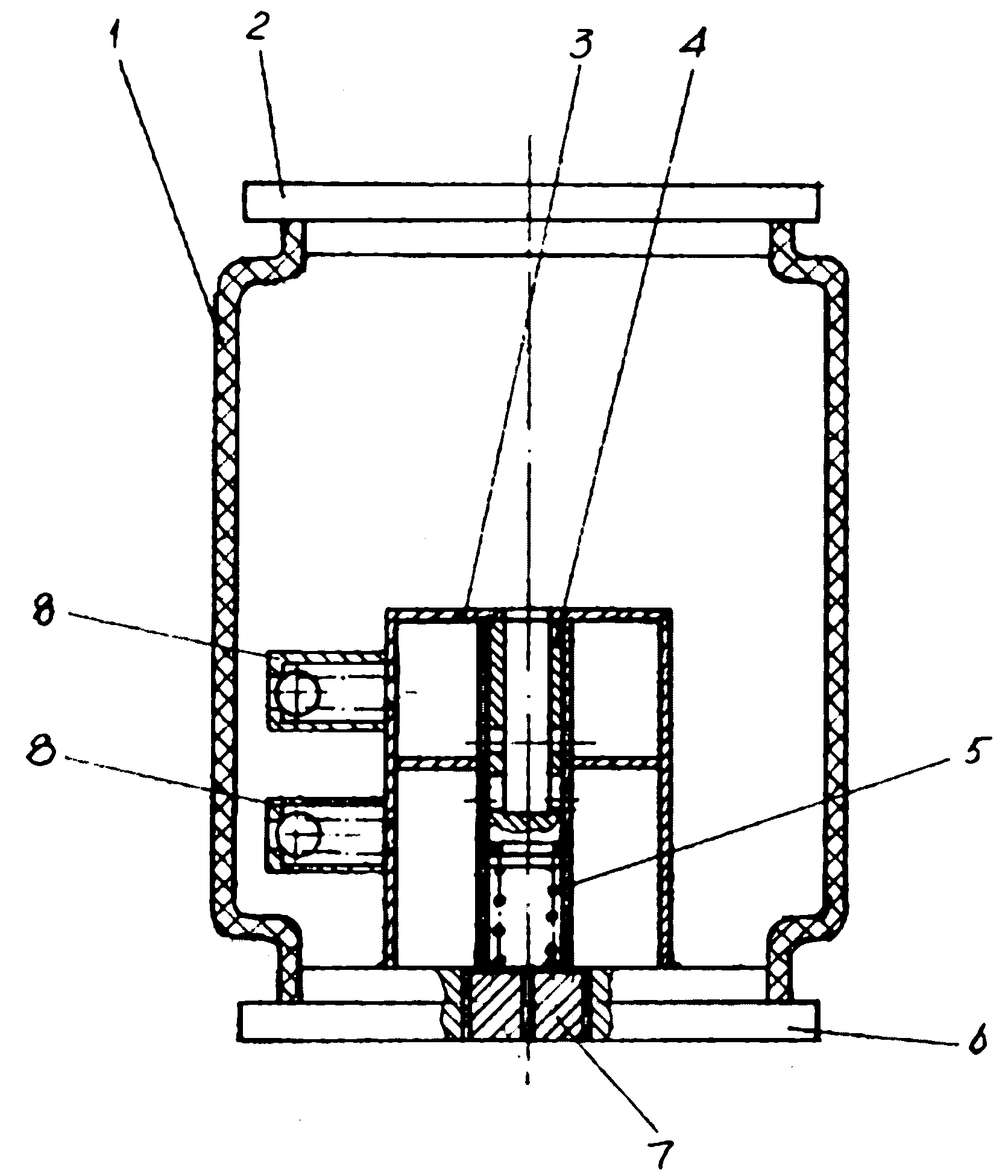

[0008] The specific embodiment of the present invention is: the dynamic stiffness adjustment of the air spring: the air pressure in the air bag 1 directly acts on the upper end surface of the throttle valve core 4, and its lower end is axially supported by the spring 5, and the vehicle is at no-load and set height At this time, the air pressure in the air spring airbag 1 multiplied by the cross-sectional area of the throttle spool 4 produces a thrust that is balanced with the spring force of the spring 5. The air chamber of the air bag is connected and is at the largest opening, and the dynamic stiffness of the air spring is the smallest; when the load and dynamic load of the vehicle increase, the air pressure in the air bag 1 rises, and the thrust generated by acting on the upper end surface of the throttle valve core 4 increases , push the throttle spool 4 to overcome the spring force of the spring 5 and move down to reach a new balance, and the throttle spool 4 moves down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com