Air spring for adjusting static stiffness and dynamic stiffness by filler and floating throttle plate

An air spring and throttling adjustment technology, which is applied in the direction of springs, spring/shock absorbers, gas shock absorbers, etc., can solve the problem that the adjustment of stiffness is not continuous, so as to achieve smooth and continuous adjustment and adjust the stiffness characteristic curve more reasonable and controllability, the effect of improving the dynamic stiffness adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

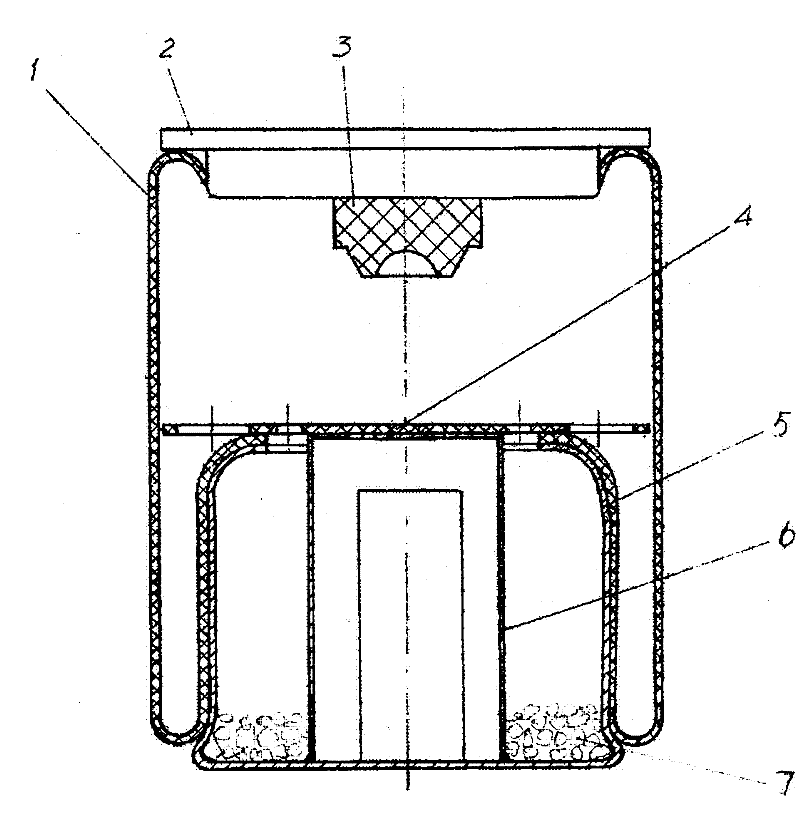

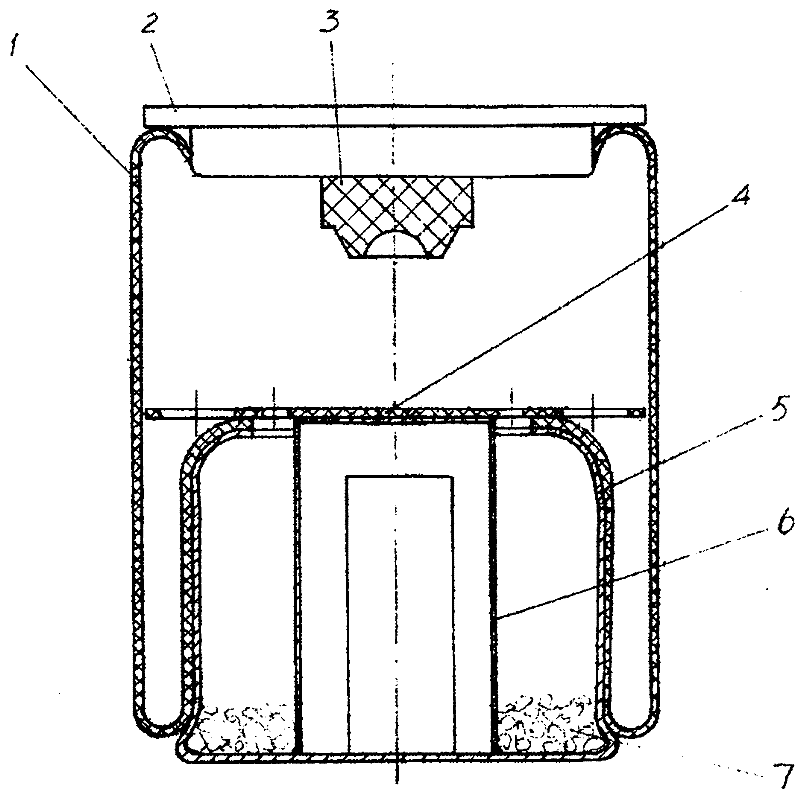

[0009] The specific embodiment of the present invention is: its static stiffness adjustment method is: when the air spring is assembled, first fill the cavity of the lower mounting seat 5 with a filler 7 whose volume has been determined through calculation or testing, and the filled filler 7 occupies the volume of the same volume of compressed air, which increases the static stiffness of the air spring; on the contrary, taking out part of the filled filler 7 increases the volume of the same volume of compressed air, which relatively reduces the static stiffness of the air spring ; Its dynamic stiffness adjustment method is: when the vehicle is stationary and in a relatively stable running state, the vehicle body does not move up and down much, and the airflow flowing through the inner ring throttle hole on the throttle adjustment plate 4 is not much, and its upper and lower surfaces have no pressure The pressure difference or the pressure difference is not large, and the thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com