Air spring with function of regulating static stiffness by filler and regulating dynamic stiffness by pressure difference

A technology of air springs and fillers, applied in elastic suspensions, transportation and packaging, suspensions, etc., can solve problems such as design errors, unsatisfactory static stiffness values of air springs, errors between performance parameters and design values, and reduce costs , The adjustment stiffness characteristic curve is reasonable and controllable, and the effect of improving the dynamic stiffness adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

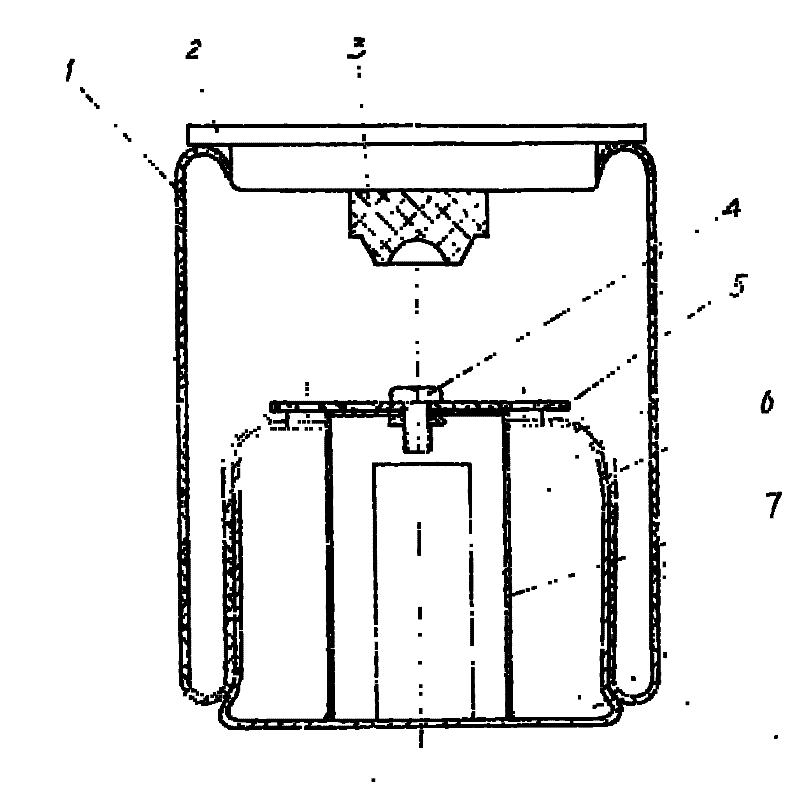

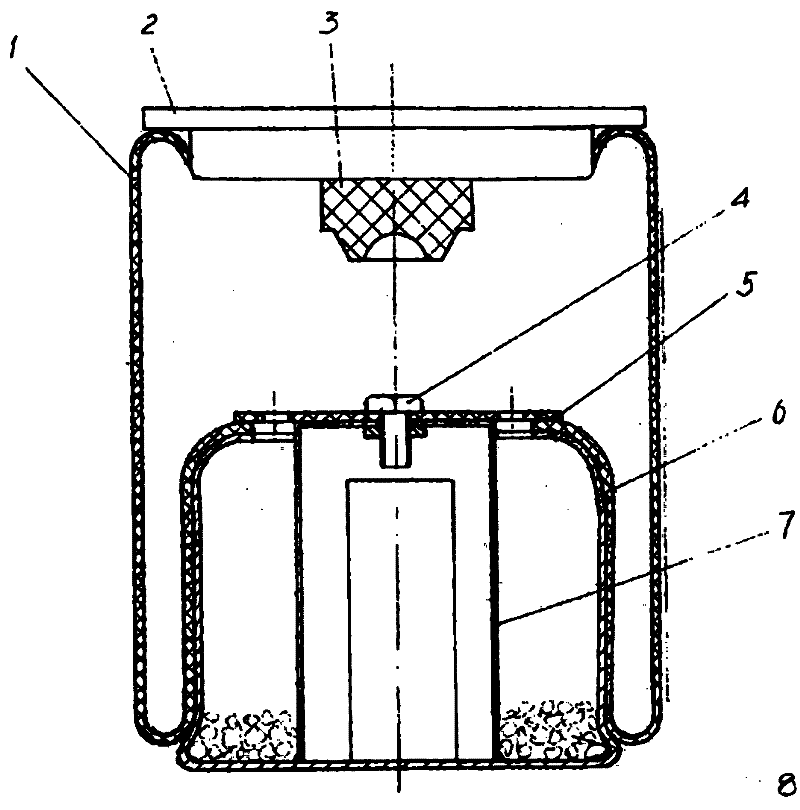

[0008] The specific embodiment of the present invention is: Static stiffness adjustment: in the assembly process of the air spring, first fill the inside of the lower mounting seat 6 into the filler 8 whose volume has been determined through calculation or testing, because the filler 8 is filled into the lower mounting seat 6 The filler 8 occupies the volume of the same volume of compressed air in the air spring, which reduces the volume of compressed air and improves the static stiffness of the air spring; on the contrary, take out part of the filled filler 8 from the lower mounting seat 6, It increases the volume of compressed air of the same volume, and relatively reduces the static stiffness of the air spring. Dynamic stiffness adjustment: when the vehicle is stationary and in a relatively stable running state, the gas flow between the airbag 1 and the lower mounting seat 6 is less, and there is no pressure difference or a small pressure difference between the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com