Shear special for plates

A technology of scissors and plates, which is applied to shearing equipment, shearing devices, and hand-held metal shearing equipment. Shear force, the effect of overcoming working strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

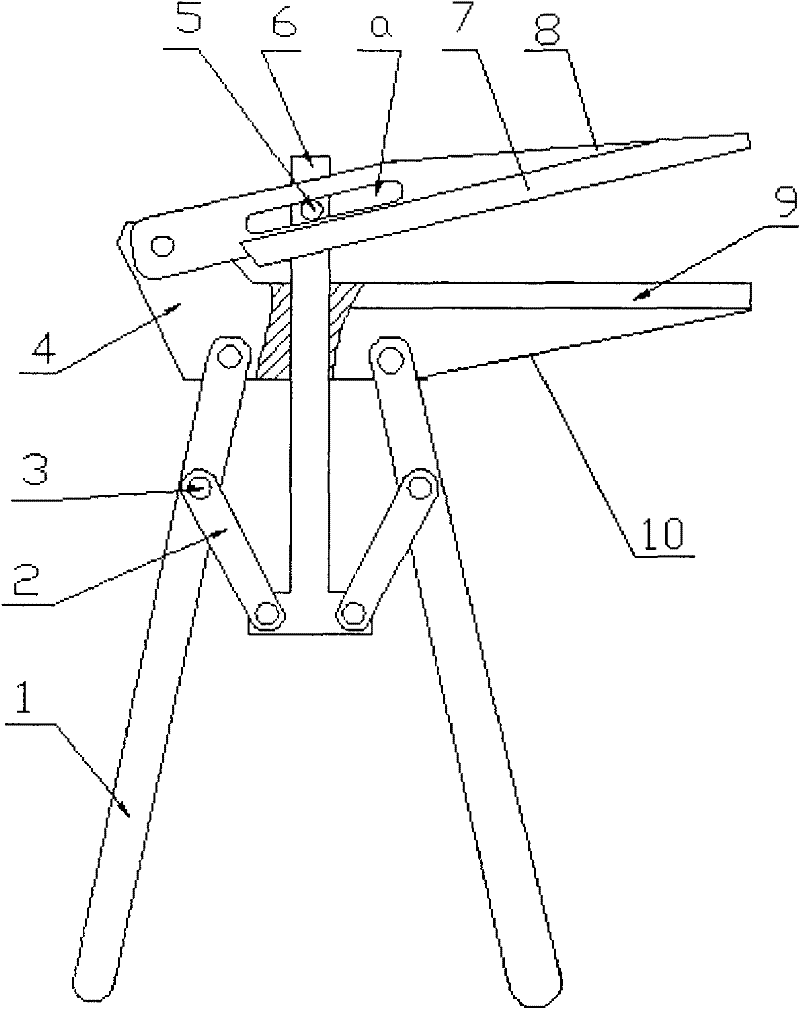

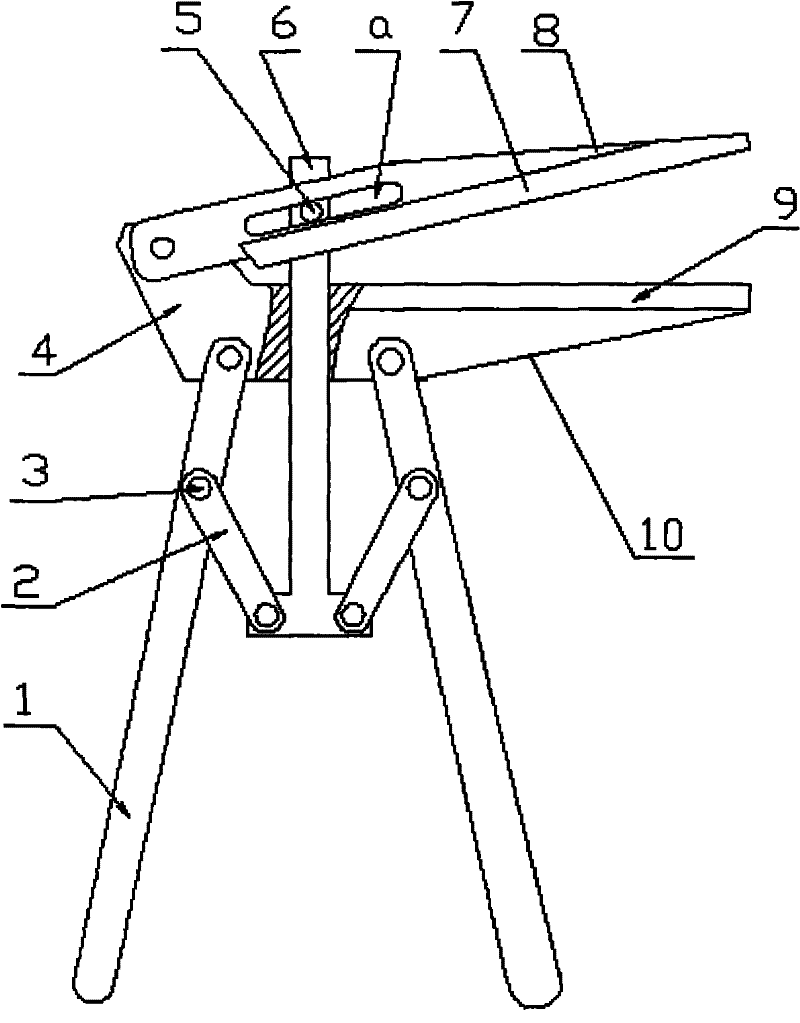

[0009] The special scissors for plate parts have a movable knife seat (8), and a long hole (a) is opened on the movable knife seat (8) along its length direction, and there is a pin at the end of the movable knife seat (8) and the fixed blade (9). The shafts (3) are hinged together, and a movable blade (7) and a fixed blade (9) are respectively installed on the inboard of the movable knife seat (8) and the fixed knife edge (9); The upper end of the pull rod (6) has a sliding pin (5) hinged in the long hole (a); the handle (1) is symmetrically installed on both sides of the lower end of the pull rod (6) by the pin (3) On the fixed knife seat (4), the two ends of the connecting rod (2) are respectively installed on the handle (1) on the left and right sides and the lower end of the pull rod (6) on both sides with the pin shaft (3), and the back of the knife (10) is connected with a Fixed knife seat (4), fixed knife seat (4) is fixed by bearing pin (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com