Circuit board manufacturing method

A technology of circuit board production and copper-clad substrate, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, and can solve problems such as image sensor deviation, photomask and circuit board alignment deviation, and circuit board scrapping. Achieve accurate alignment, improve signal transmission quality, and prevent excessive alignment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The circuit board manufacturing method of the technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

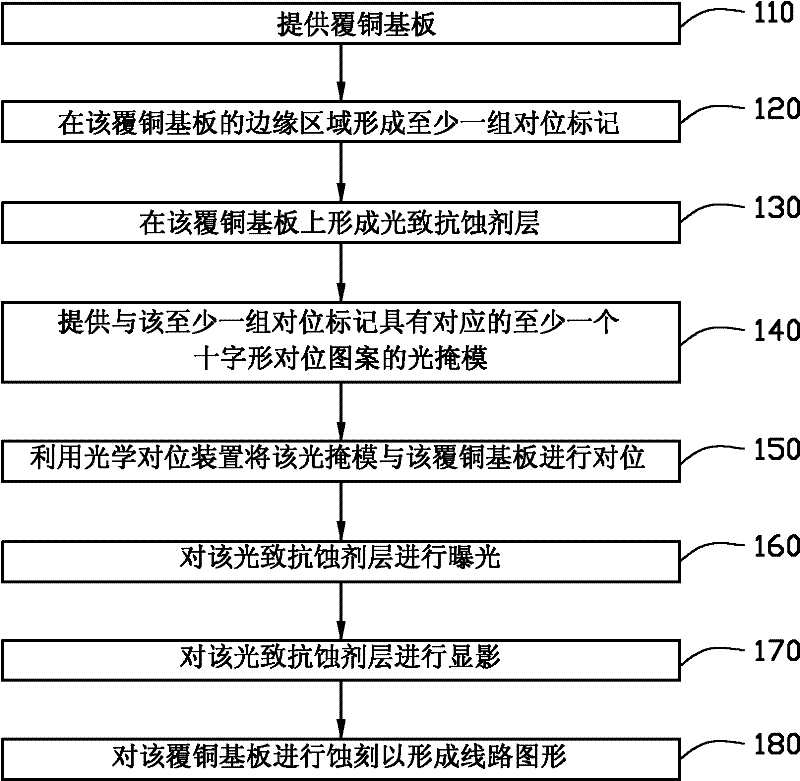

[0055] see figure 1 , the embodiment of the technical solution provides a circuit board manufacturing method, which includes the following steps:

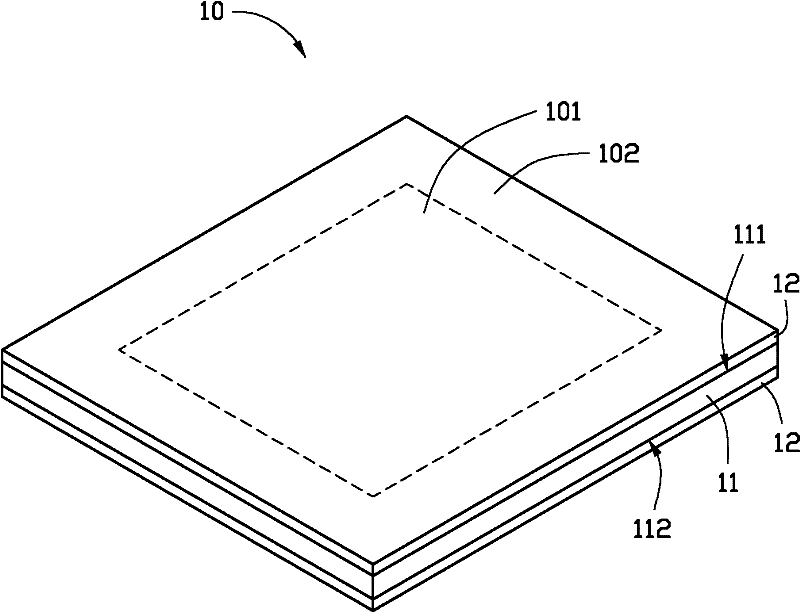

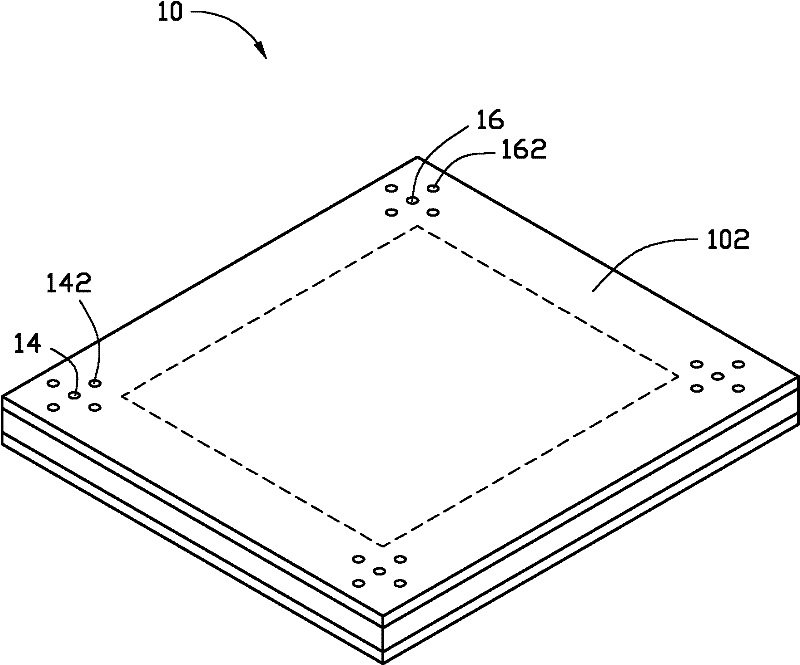

[0056] Step 110, see figure 2 , providing a copper clad substrate 10 .

[0057] In this embodiment, the copper clad substrate 10 includes a first insulating layer 11 and a first copper foil layer 12 . The first insulating layer 11 has a first surface 111 and a second surface 112 opposite to each other. The first surface 111 is parallel to the second surface 112 . A first copper foil layer 12 is disposed on the first surface 111 and the second surface 112 respectively, that is, the copper clad substrate 10 is a double-sided board. Of course, the copper-clad substrate 10 can also be a single-sided board with only one first copper foil layer 12 . The c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap