A flip-chip packaging product without conductive adhesive and its manufacturing process

A technology of chip packaging and manufacturing process, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of large thickness, high cost, and expensive material cost, and achieve cost reduction, high practicability, and chip reduction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

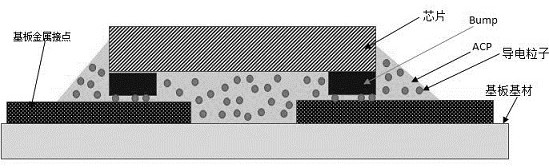

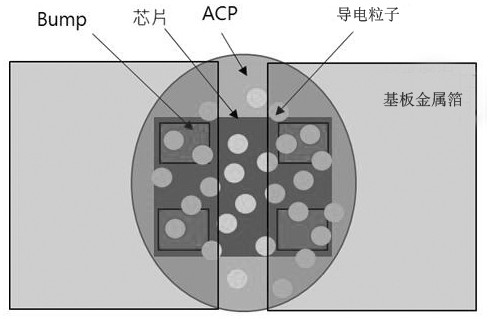

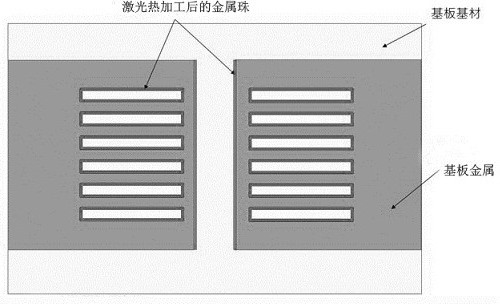

[0029] A flip-chip packaging product that does not use conductive glue, including flip-chip packaging chips and substrates, and the metal foil on the substrate is heated and melted into metal beads. The metal beads are distributed on the substrate contacts and filled between the chip and the substrate. Non-conductive structural glue (thermosetting glue or UV glue), so that the metal beads on the substrate contact or embed on the Bump of the chip or the PAD of the chip.

[0030] The above-mentioned metal beads are made of aluminum, copper, silver, tin, gold-plated copper, tin-plated copper, nickel-plated gold or copper-plated tin-lead.

[0031] The above-mentioned substrates are PET+aluminum flexible substrate, PET+copper flexible substrate, PI+aluminum flexible substrate, PI+copper flexible substrate, FR4+copper substrate, FR4+aluminum substrate, BT+copper substrate or BT+aluminum substrate.

[0032] The Bump or PAD material on the chip above is gold, silver, copper, aluminum,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap