Centrifugal field slope pile driving system

A centrifugal field and slope technology, which is applied in the direction of sheet pile wall, foundation structure test, construction, etc., can solve the problems that the influence of slope deformation cannot be considered, and the pile entry conditions cannot be simulated, so as to achieve easy transformation, low cost, The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings.

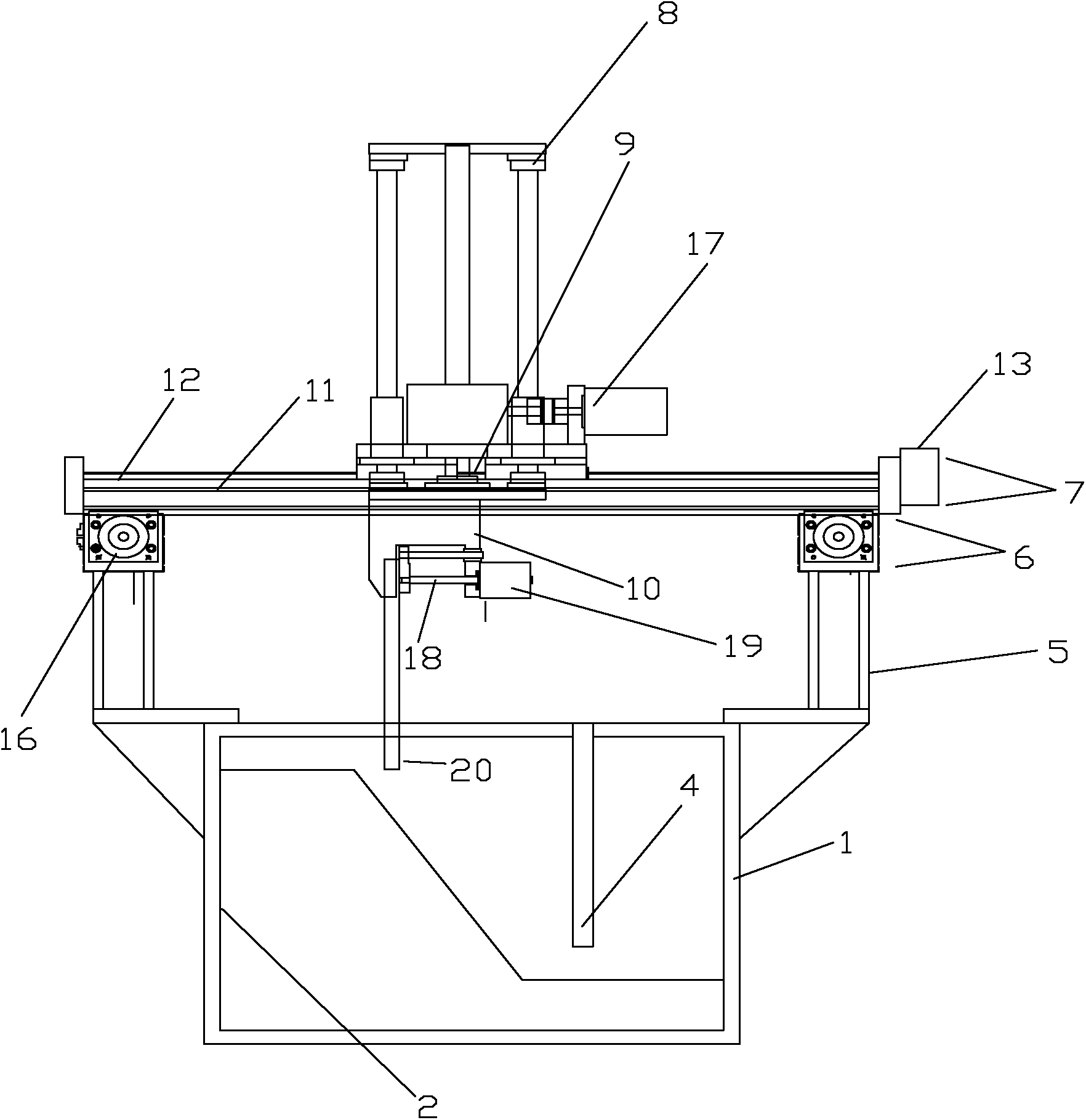

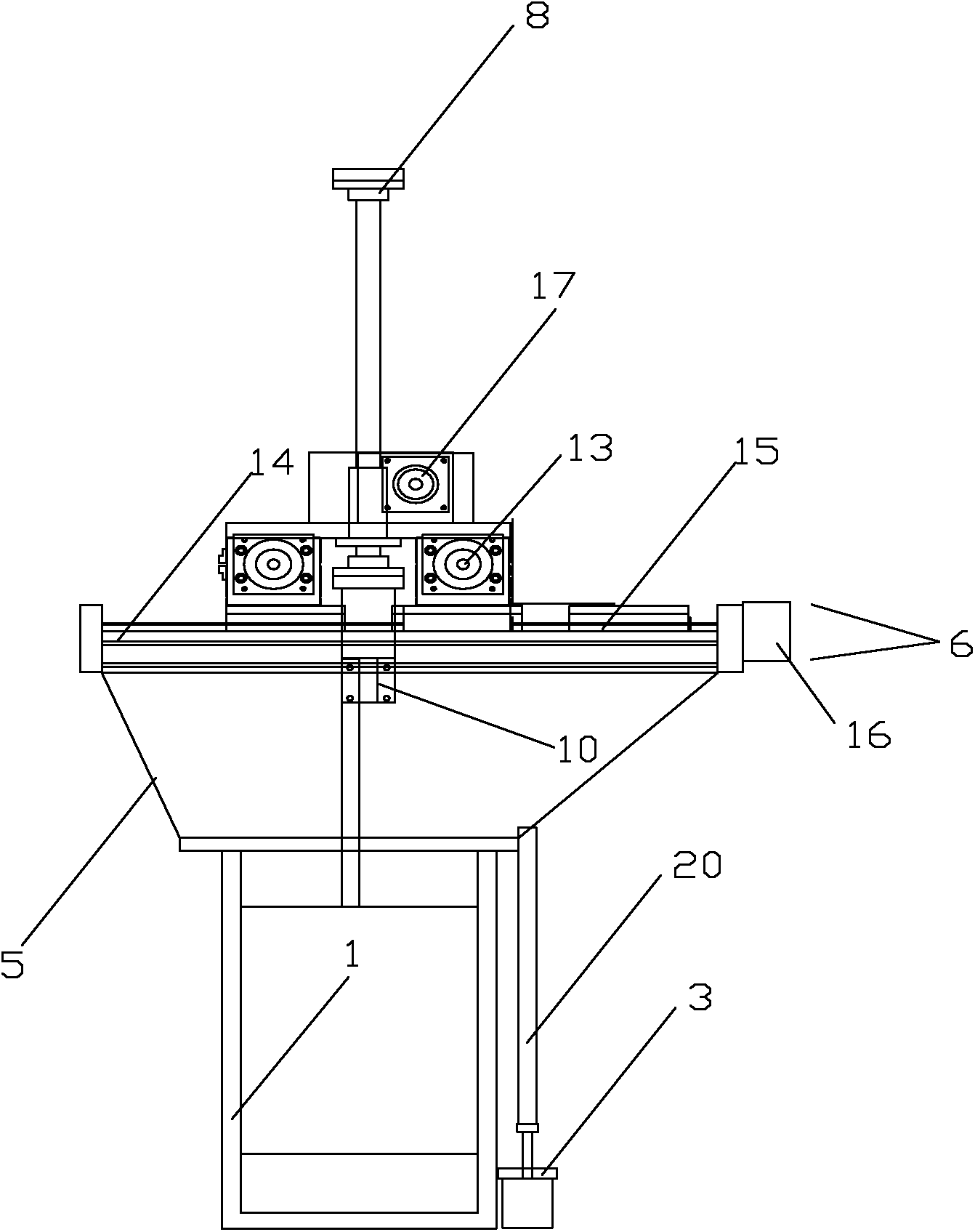

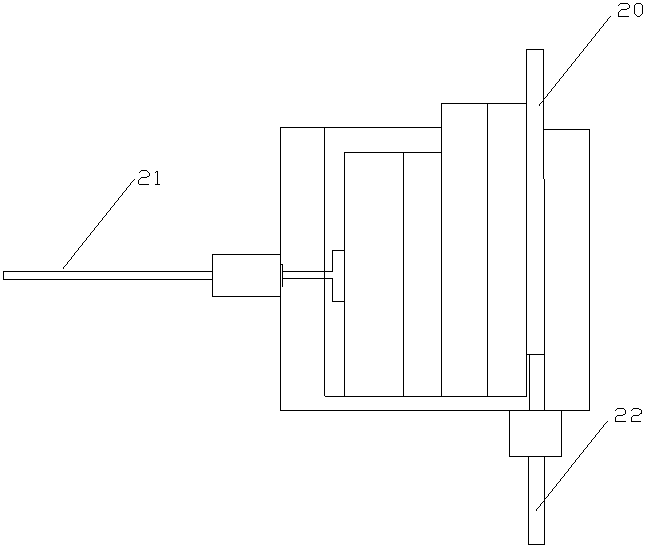

[0017] Such as figure 1 and figure 2 As shown, the centrifugal field side slope pile entry system includes a pile storage mechanism 3 installed on the opposite surface adjacent to the window 2 of the model box 1, and the opposite surface of the model box 1 is provided with an anti-slide pile entrance groove 4. A system rack 5 is installed above the model box 1, and a longitudinal Y-direction linear motion subsystem 6 and a lateral X-direction linear motion subsystem 7 are installed in sequence on the system rack 5, which is called a shifting mechanism, on which is a press The pile-pressing mechanism 8 that pile T-shaped leading screw 9 is connected, the bottom end of pile-pressing T-shaped leading screw 9 is equipped with clamping manipulator 10. Such as image 3 As shown, the pile storage mechanism 3 includes a push mechanism 22 and a side push mechanism 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com