Device for mounting buckle on sealing strip

A sealing strip and buckle technology, applied in the field of sealing strip assembly assembly equipment, can solve problems such as low installation efficiency of the device, and achieve the effect of improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

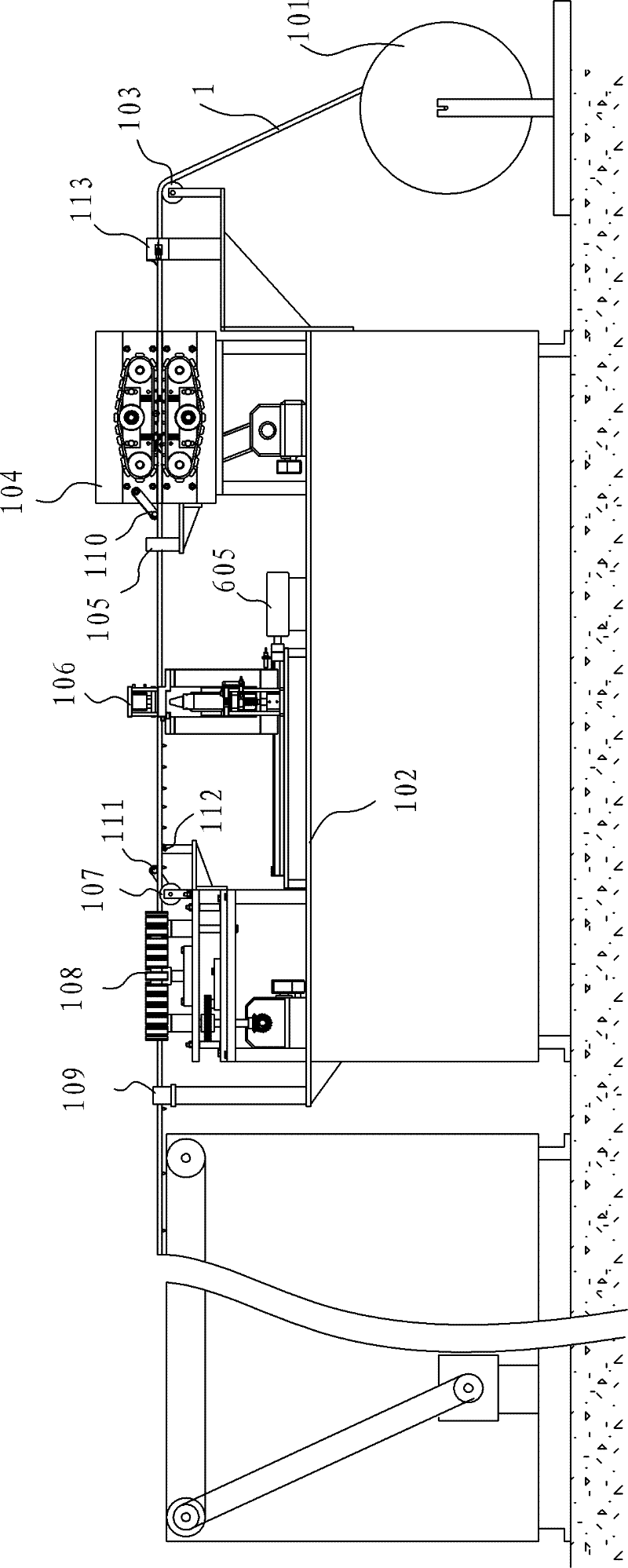

[0044] Such as figure 1 As shown, a device for installing the buckle on the tubular sealing strip on the door of an oven, etc., includes a material rack 101 and a workbench 102, and the workbench 102 is provided with guide wheels 103, front traction mechanism 104, Caliper 105, installation unit 106, guide wheel 107, rear traction mechanism 108, cutting mechanism 109.

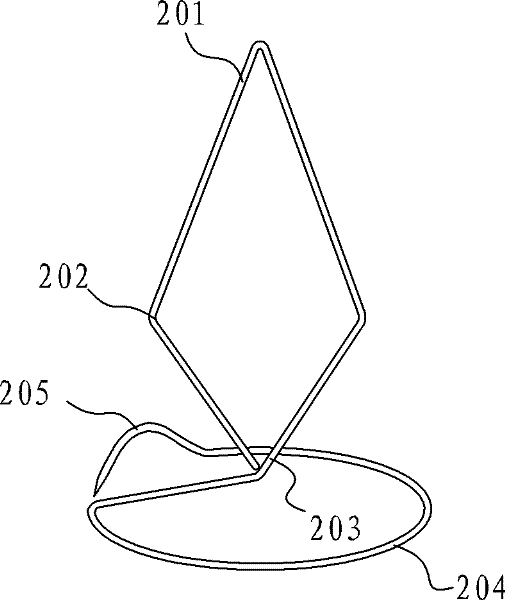

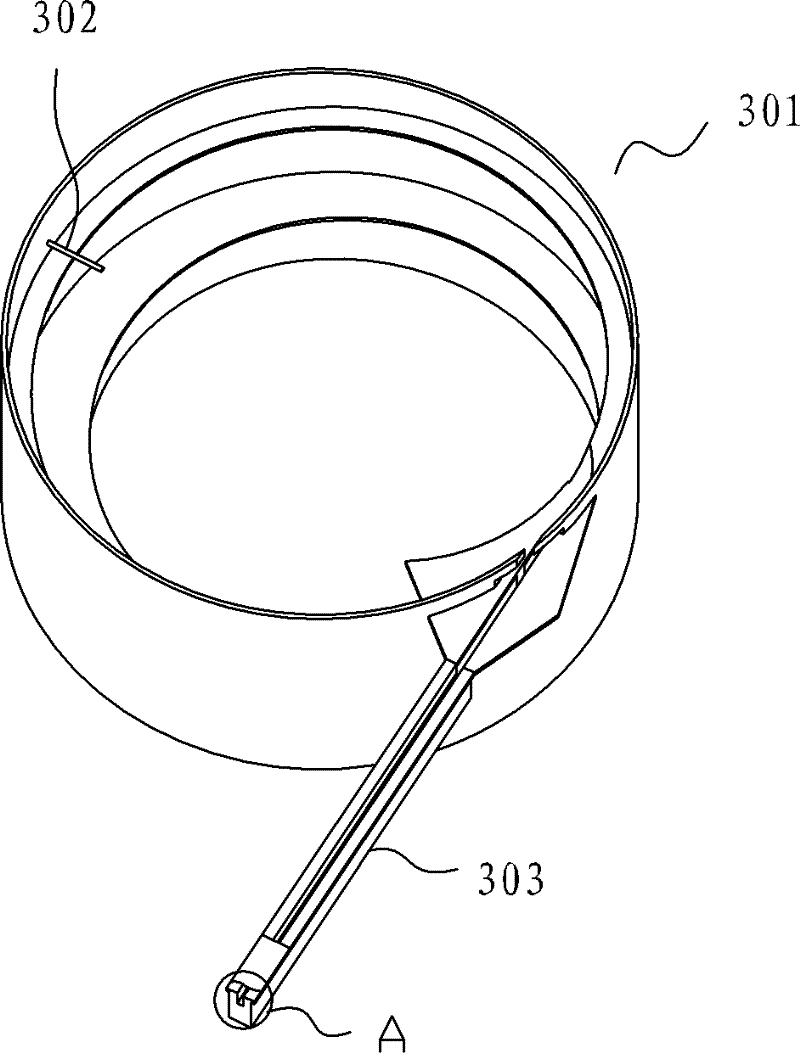

[0045]The above-mentioned sealing strip has a double-layer structure, the inner layer is a metal mesh, or a glass fiber rope, and the outer layer is a glass fiber sleeve. The above-mentioned buckle is figure 2 The buckle shown can also be the buckle disclosed in Chinese patents 200820164622.8 and 200920120533.8, which is made by bending a single elastic metal wire, including a head 201, two shoulders 202, a neck 203 and an annular The base 204 has a wave-shaped protrusion 205 perpendicular to the plane where the base is located, and the descending section of the wave-shaped protrusion 205 is just the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com