Quick wiring terminal

A fast technology for connecting terminals, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of reducing wiring efficiency, cumbersome operation, increasing production costs, etc., and achieve the effect of improving wiring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

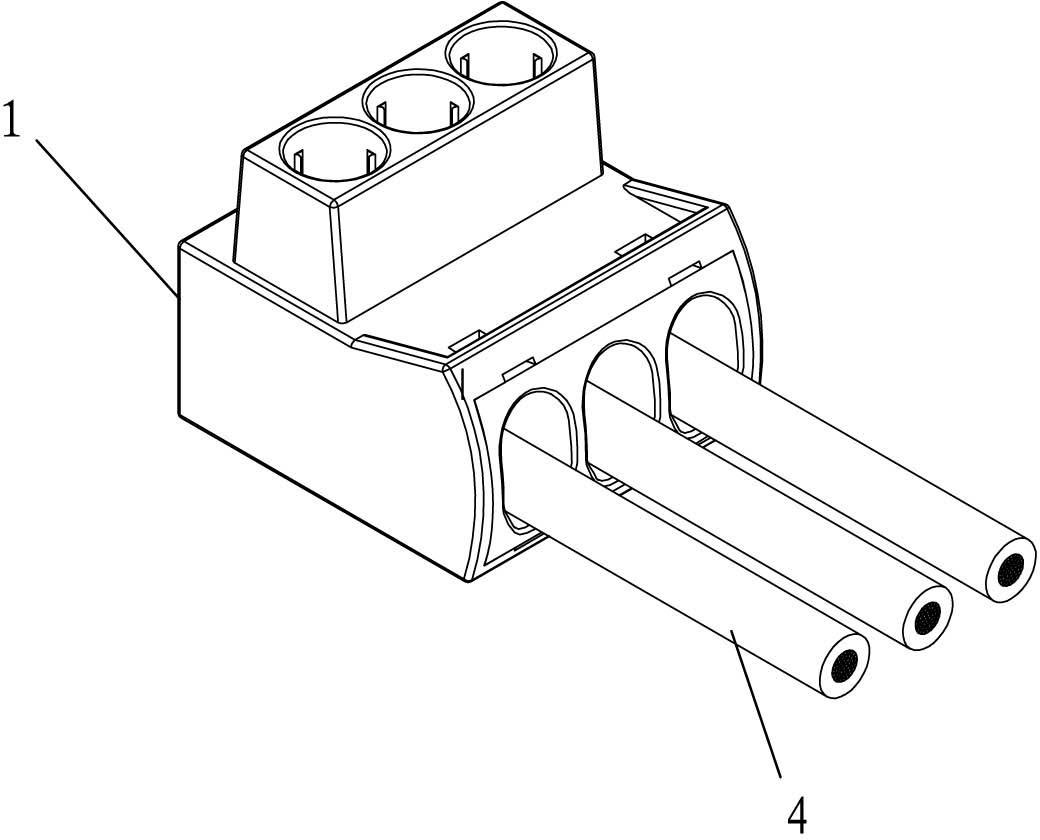

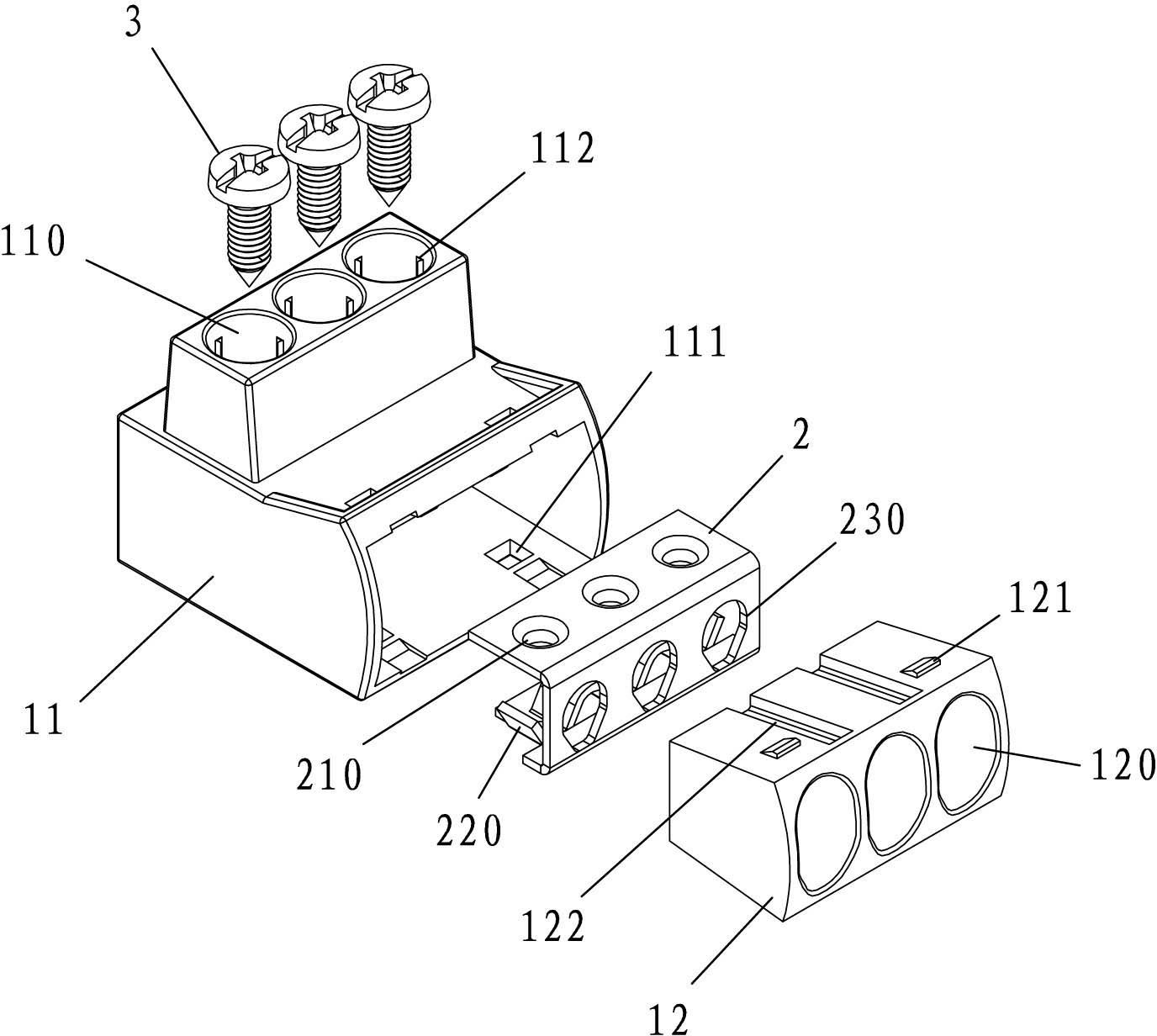

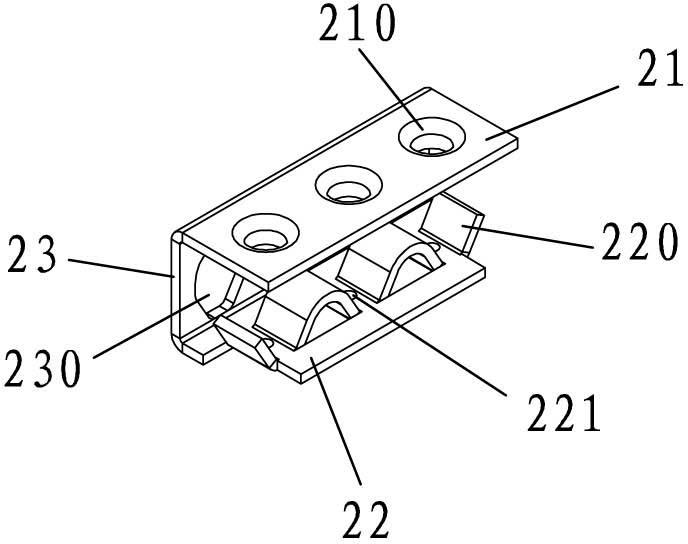

[0024] refer to Figure 1 to Figure 7 , a quick connection terminal of the present invention, including a housing 1, a conductive block 2 arranged in the housing 1, a bolt 3 arranged on the conductive block 2 for tightening the wire 4, the housing 1 is composed of a housing 11 and a cover 12 Assembled, the conductive block 2 is set in the casing 11, the pressing cover 12 is arranged in front of the conductive block 2 and the conductive block 2 is pressed into the casing 11, and the pressing cover 12 is provided with an outwardly protruding hook 121. The inner wall of the body 11 is provided with a slot 111 matched with the hook 121. After the cover 12 is inserted into the housing 11, the hook 121 is hooked in the slot 111, so that the press cover 12 and the housing 11 are assembled and fixed, and it is not easy to fall off. , The cover 12 is provided with a guide groove 122, and the housing 11 is provided with a guide block 114 matching the guide groove 122. The guide groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com