Aperture flat cable applicable to multi-directional rotating shafts

A rotating shaft and threading technology, which is applied in the direction of contact parts, printed circuit parts, electrical components, etc., can solve the problems of cable distribution capacitance change, mutual scratching, affecting layers, etc., to improve reliability, prolong life, The effect of stabilizing electrical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

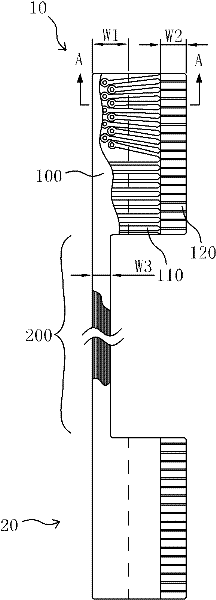

[0036] Such as figure 1 As shown, a top view of the embodiment of the present invention; the piercing section 200 is a long and narrow sheet, which is formed on the same flexible circuit board as the first joint 10 and the second joint 20; the first joint 10 includes three parts respectively The transition section 100, the bending section 110 and the first cable end 120, and the extension direction of these three parts is perpendicular to the extension direction of the piercing section 100 - the purpose of this setting is to make the first joint 10 fold (or After crimping), its form can form a shape with a width comparable to that of the passing section 200, so that it can pass through the shaft hole; usually, when the first joint 10 is folded (or crimped), the transition section 100 and the first cable end The shape of 120 basically remains unchanged, but the bending section 110 is curled or bent, so that the bending will not stretch and damage the static discharge layer on t...

Embodiment 2

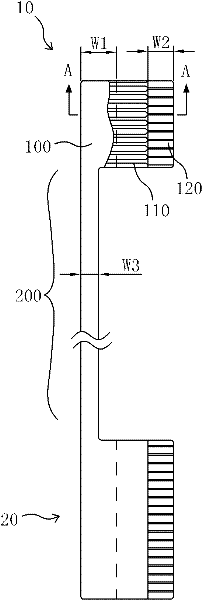

[0041] Such as figure 2 , the top view of the second embodiment of the present invention; compared with the embodiment, the penetration section 200 and the second joint 20 are the same, the difference is the first joint 10 . In the second embodiment, the first joint 10 also has the transition section 100, the bending section 110 and the first cable end 120, but the wiring from the piercing section 200 does not pass through the via hole, and the second is to directly pass through the transition section on both sides. 100. The bending section 110 is finally connected to the golden fingers on the first cable end 120 in one-to-one correspondence; the relationship between the width W1 of the transition section 100, the width W2 of the first cable end, and the width W3 of the piercing section are all implemented in the same manner example one.

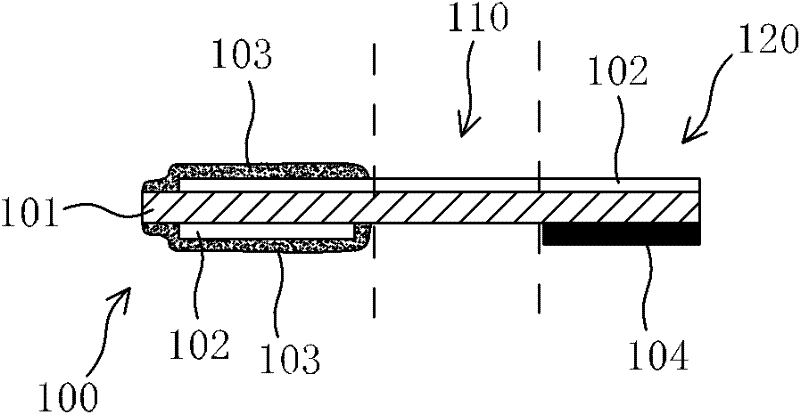

[0042] to combine Figure 4 It can be seen figure 2 Sectional detail of part AA in middle. In the transition section 100, its antista...

Embodiment 3

[0044] Such as Figure 5, the top view of the first joint of the third embodiment of the present invention; the passing section 200, the transition section 100, the bending section 110, the first cable end 120 and other unmarked parts of this embodiment are the same as those of the first embodiment; the difference What is more important is that there is a ground welding spot 109 at the top of the transition section 100 , and the ground welding spot 109 communicates with the conductive trace serving as the ground wire in the penetration section 200 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap