Air purifying device for glass bottled draught beer filling line

An air purification device and glass bottle technology, applied in the field of air purification systems, can solve the problems of 10,000-level air not meeting the sterile requirements, pure draft beer pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

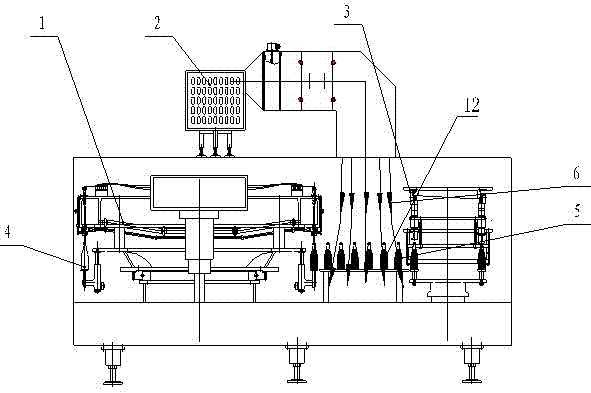

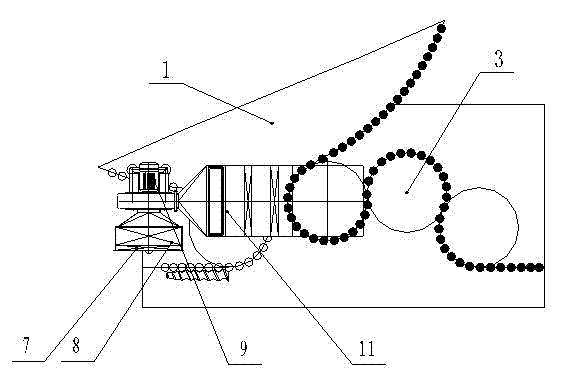

[0011] Such as figure 1 with figure 2 As shown, the empty glass bottle 4 is input into the filling machine 1, and the pure draft beer is poured into the empty glass bottle 4 by the filling machine 1, and then the glass bottle 5 filled with pure draft beer is sent into the gland through the bottle feeding star wheel 12 The machine 3 presses the cap, when the glass bottle 5 containing pure draft beer passes through the bottle conveying star wheel 12, the 100-grade air purification system 2 will blow out the sterile 100-grade air 6, so that the glass bottle 5 containing pure draft beer passing through the bottle conveying star wheel 12 The air that the glass bottle 5 of draft beer contacts is aseptic 100-grade air, guarantees that pure draft beer is not polluted by microorganisms in the air. The 100-level air purification system 2 is composed of the primary effect filter 7, the medium-efficiency filter 8, the air intake blower 9 and the high-efficiency filter 11; when the 100-l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap