Support frame for supporting casting blank on electric flat car

A technology of over-straddle car and support frame, applied in the field of support frame, can solve problems such as billet bending, and achieve the effect of avoiding bending deformation, increasing bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

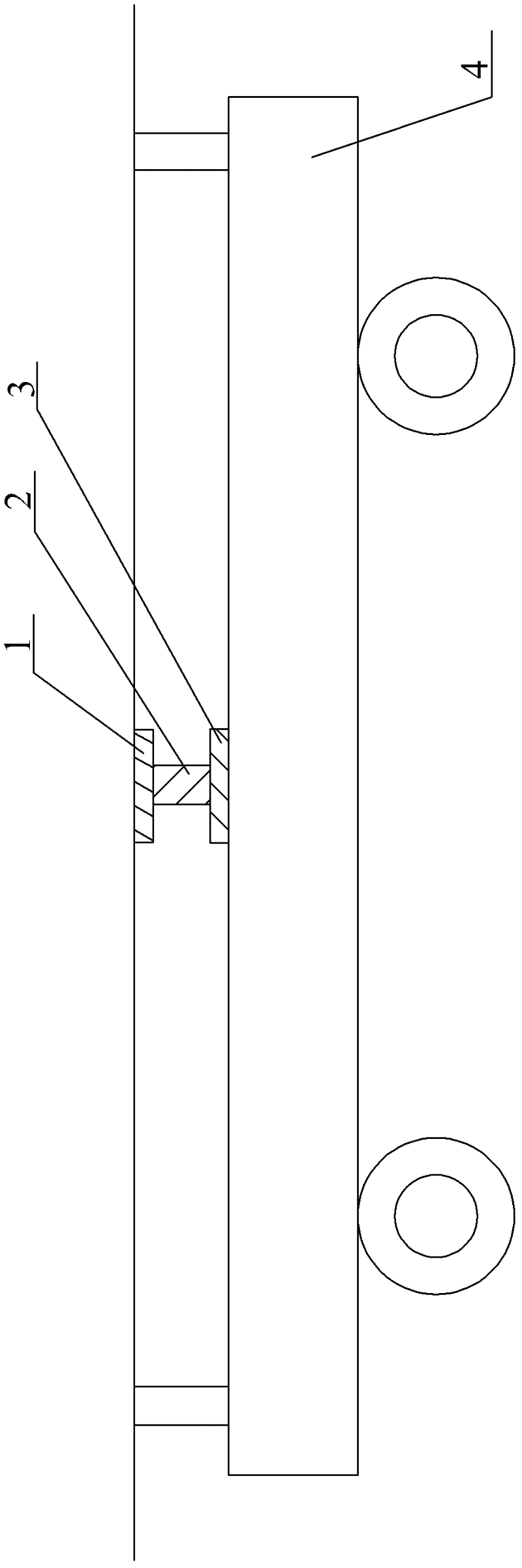

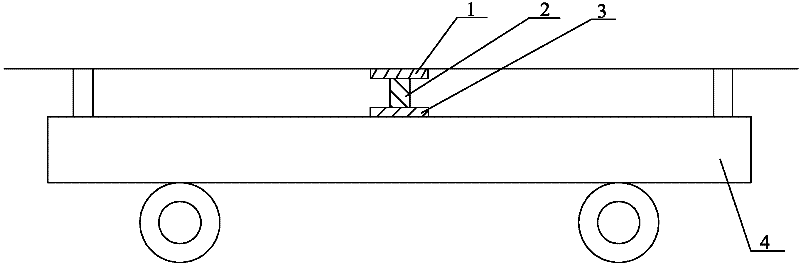

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the support frame that is used to support the cast slab on the over-span car of this embodiment includes upper horizontal plate 1, lower horizontal plate 3 and vertical plate 2, and vertical plate 2 is arranged on the upper horizontal plate 1 and the lower horizontal plate that are arranged in parallel. Between the cross plates 3 and the three are connected as a whole, the lower end surface of the lower cross plate 3 is connected with the upper end surface of the straddle car 4, and the upper end face of the upper cross plate 1 is connected with the supports on both sides of the straddle car 4. The upper end surfaces are on the same level, the support frame is located in the middle of the supports on both sides of the span car and the three are located on the same level.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To describe this embodiment, the connection method of the upper horizontal plate 1 , the lower horizontal plate 3 and the vertical plate 2 described in this embodiment is welding. Such setting meets the design requirements. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com