Slide rail structure and automatic business device

The technology of an automatic transaction device and a slide rail is applied to a device for accepting coins, a casing of an automatic teller machine, parts of an automatic teller machine, etc. Cost-reducing, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

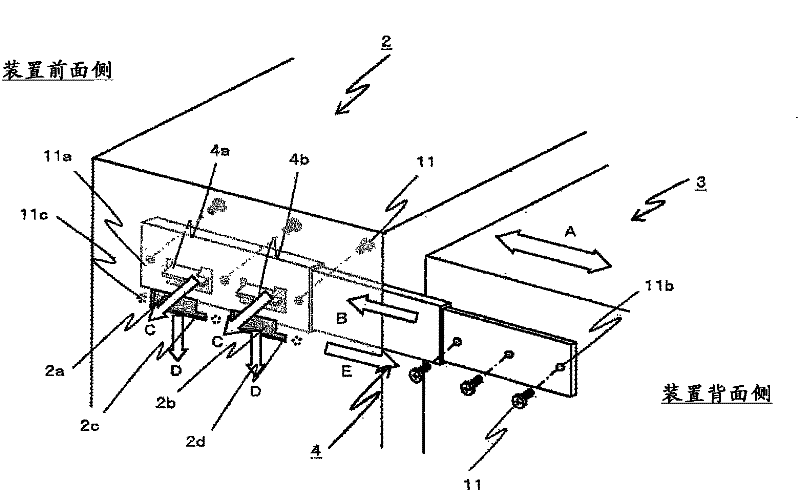

[0025] (constitute)

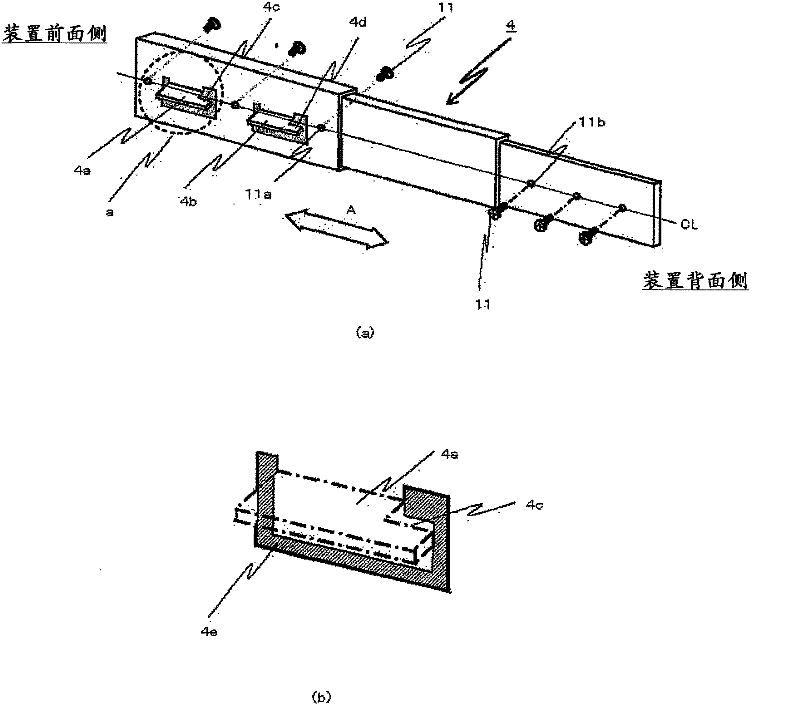

[0026] figure 1 (a) is the overall configuration diagram of the slide rail 4 of embodiment 1, figure 1 (b) for figure 1 (a) Enlarged view of part a of the dotted line part. As shown in this figure, the slide rail 4 of Embodiment 1 is equipped with: L-shaped curved portions 4a, 4b on the side surface of the device front side of the slide rail 4, and the L-shaped curved portions 4a, 4b are as follows: figure 1 (b) The U-shaped punching part 4e of the hatched part shown in (b) is punched out and formed by L-shaped bending; 4, and is configured such that a threaded hole 11b for fixing the unit 3 and the slide rail 4 is provided on one side surface of the slide rail 4 on the back side of the device main body 2. Notches 4c, 4d are provided on the device back side of the L-shaped bent portions 4a, 4b.

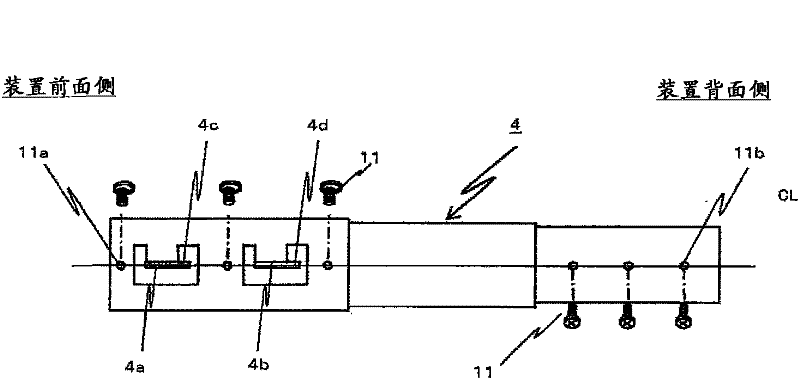

[0027] figure 2 is a side view of the slide rail 4. As shown in the figure, the L-shaped bent portions 4 a, 4 b and the threaded holes 11 a, 11 b are...

Embodiment 2

[0046] (constitute)

[0047] Figure 6 (a) is the configuration diagram of the slide rail 14 of embodiment 2, Figure 6 (b) for Figure 6 (a) Enlarged view of part a of the dotted line part. As shown in this figure, the slide rail 14 of Embodiment 2 has L-shaped curved portions 14a, 14b opposite to the L-shaped curved portions 4a, 4b of the slide rail 4 of Embodiment 1 in the direction of arrow A, so as to achieve easier installation. Purpose on device body 2.

[0048] That is, the slide rail 14 of the second embodiment is provided with: L-shaped curved portions 14a, 14b which are formed by connecting one side surface of the slide rail 14 on the side of the device main body 2 such as Figure 6 (b) The U-shaped punching part 14e of the oblique line part is punched and formed by L-shaped bending; and the threaded hole 11a is used to fix the device main body 2 and the slide rail 14 by screws 11, Furthermore, the slide rail 14 is configured such that a screw hole 11 b for fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com