Active-control hydraulic type rub-impact fault detection test apparatus

A technology of active control and experimental equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of failure simulation of rubbing failures, inability to accurately control the movement and stress of rubbing parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

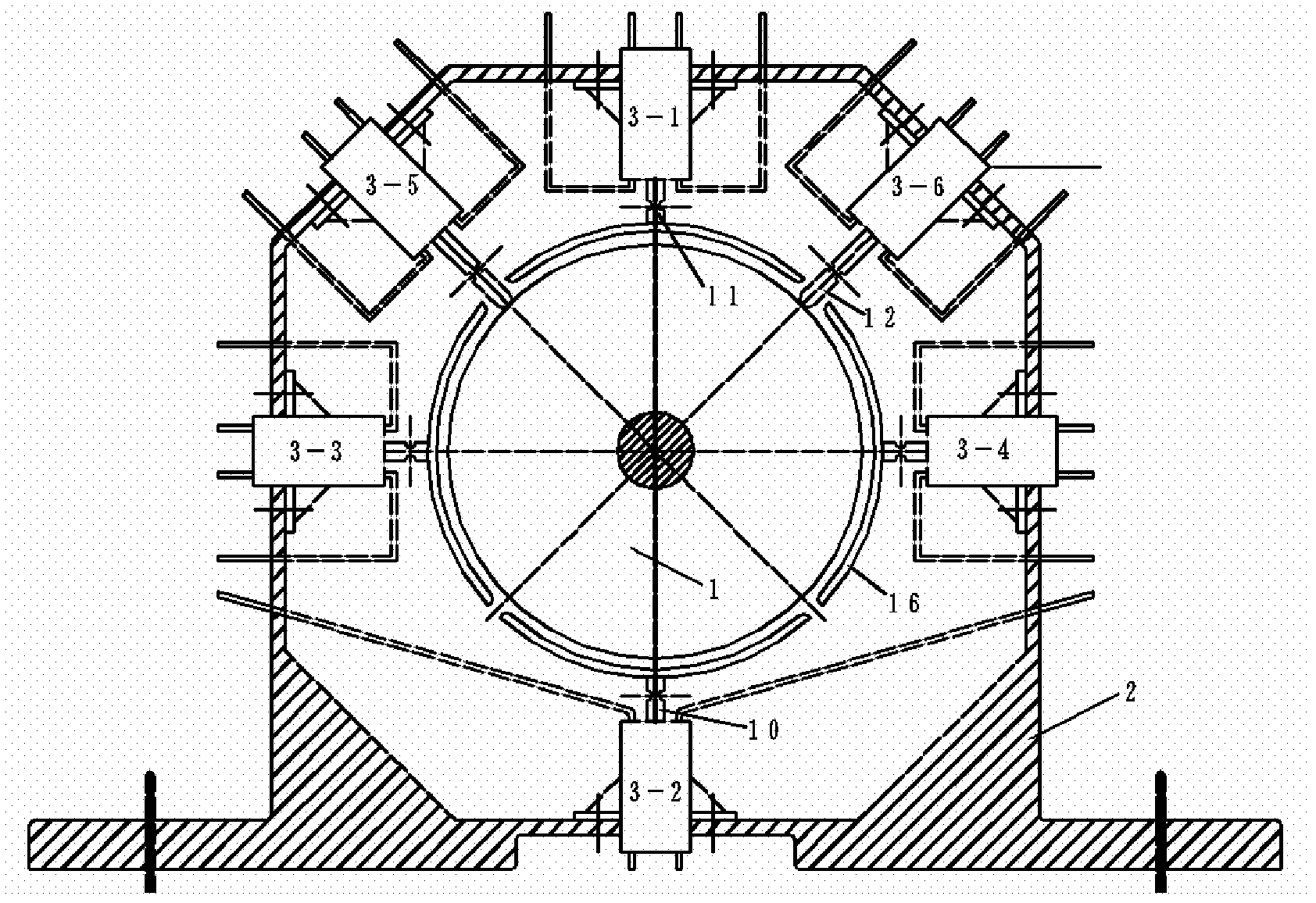

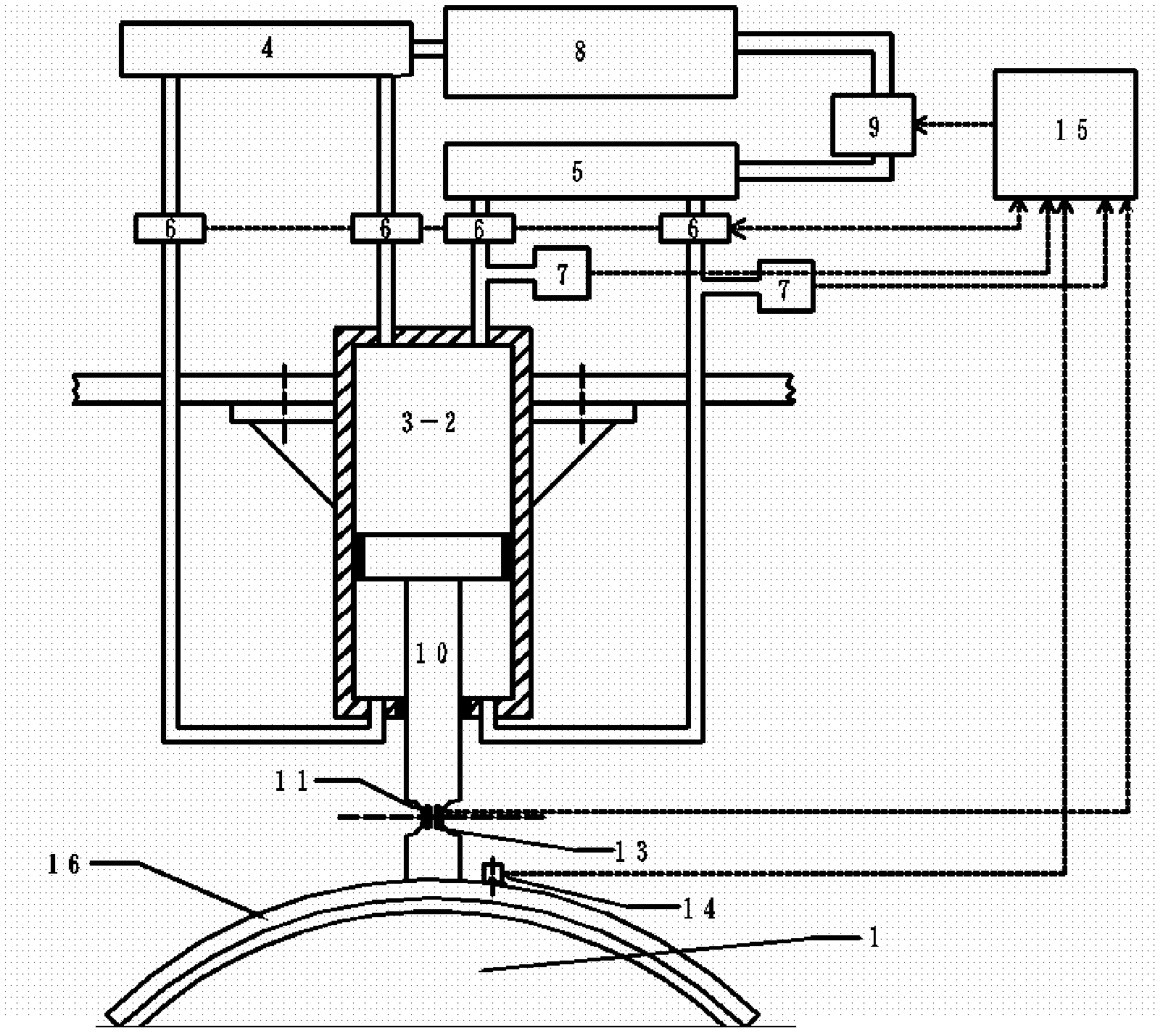

[0013] Actively controlled hydraulic rubbing fault detection experimental device consists of hydraulic cylinder, piston connecting rod, hydraulic oil return tank, constant pressure tank, electromagnetic pressure regulating valve, pressure sensor, oil storage tank, oil pump, elastic hinge and rubbing column. Drive System. The connection structure of its components is: the rotor wheel 1 is placed in the test bench 2 through the rotor main shaft, and the outer periphery of the rotor wheel is equipped with 6 sets of hydraulic drive systems. Hydraulic cylinders 3-1, 3-2, the third and fourth hydraulic cylinders 3-3, 3-4 are respectively provided in the horizontal direction of the rotor disc, with the horizontal direction of the center of the rotor disc bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com