Energy-saving water supply equipment of high-rise building

A technology for water supply equipment and high-rise buildings, applied in buildings, water supply devices, water supply main pipelines, etc., can solve the problems of low efficiency of small flow pumps and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

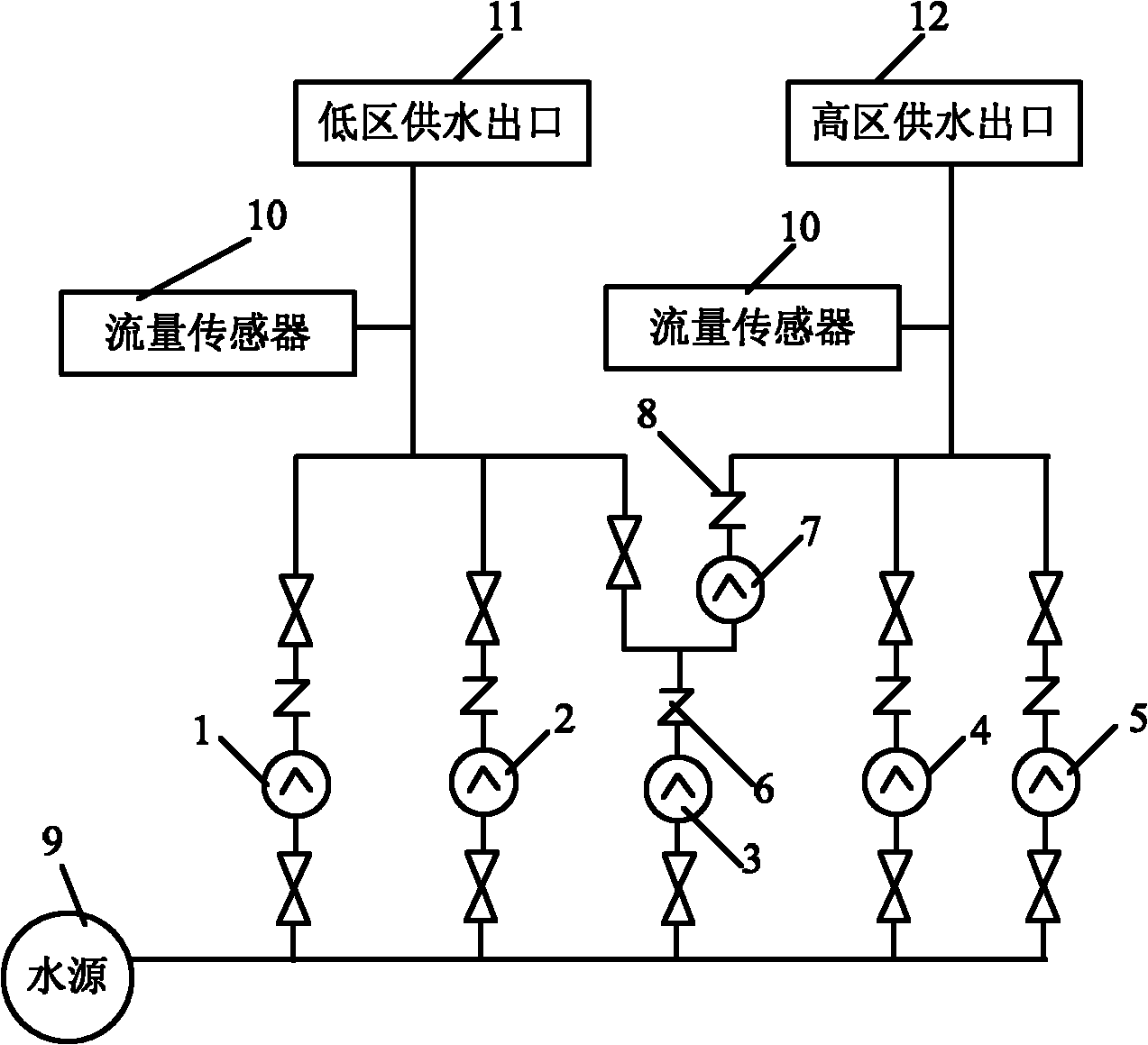

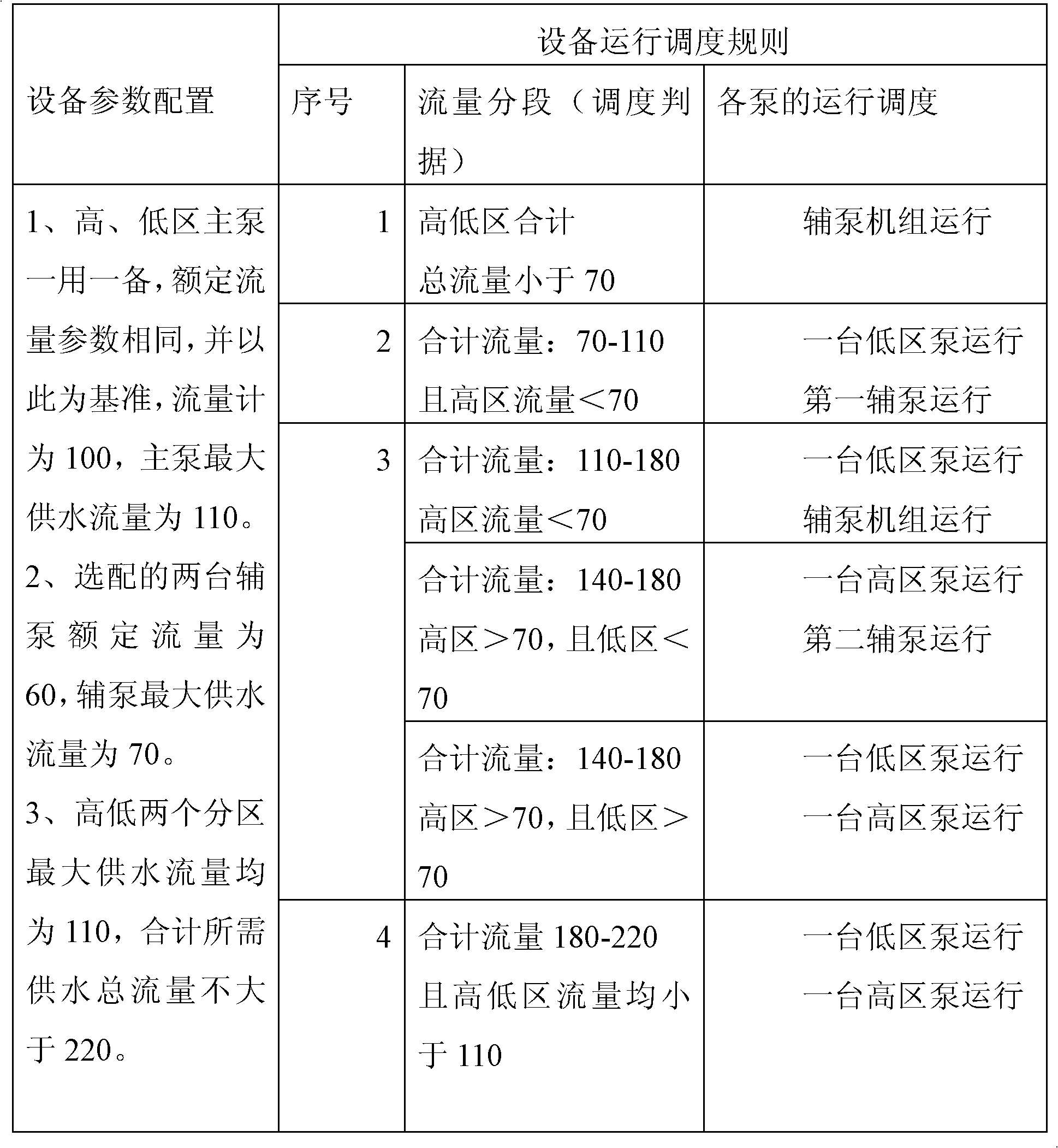

[0015] Such as figure 1 As shown, the energy-saving water supply equipment for high-rise buildings of the present invention includes a low-zone booster unit, a high-zone booster unit, an auxiliary pump unit, a first check valve 6, and a second check valve 8, wherein the low-zone booster unit includes the first The first low-zone main pump 1 and the second low-zone main pump 2 (the number of low-zone main pumps is more than two) and their supporting valve pipelines, the first low-zone main pump 1 and the second low-zone main pump 2 are connected in parallel , as required, the low-zone booster unit can also be equipped with more main pumps (not shown in the figure), and the high-zone booster unit includes the first high-zone main pump 4, the second high-zone main pump 5 (high-zone main pump The quantity is tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com