Secondary cooling water amplitude-cutting control method of slab continuous casting machine

A technology of slab continuous casting machine and control method, which is applied to the online adjustment of cooling water spray width, the field of online width cutting control of the inner arc secondary cooling water spray width of wide and thick slab continuous caster, and can solve the spray width control accuracy Poor quality, high cost, large amount of transformation and other problems, to achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

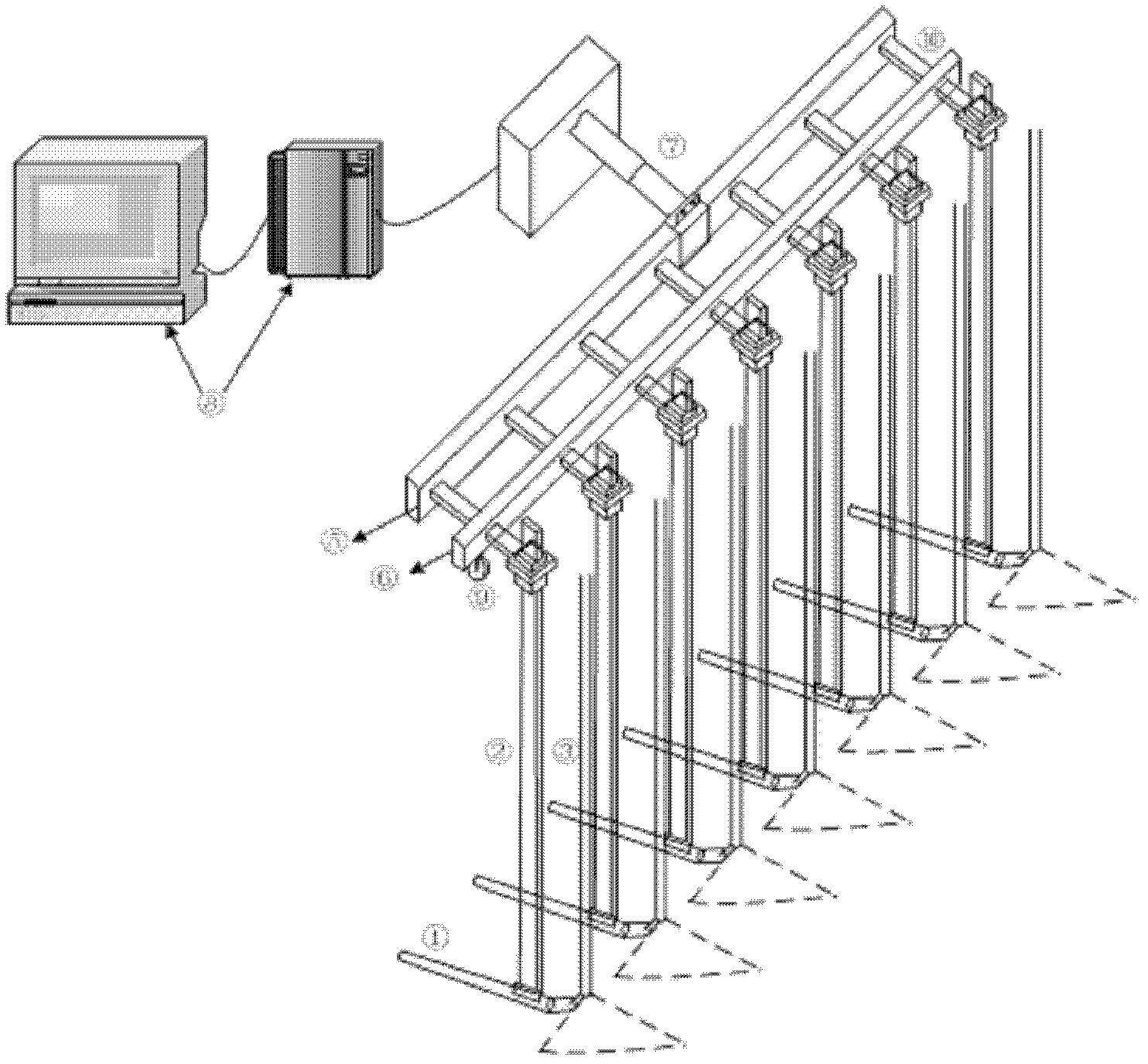

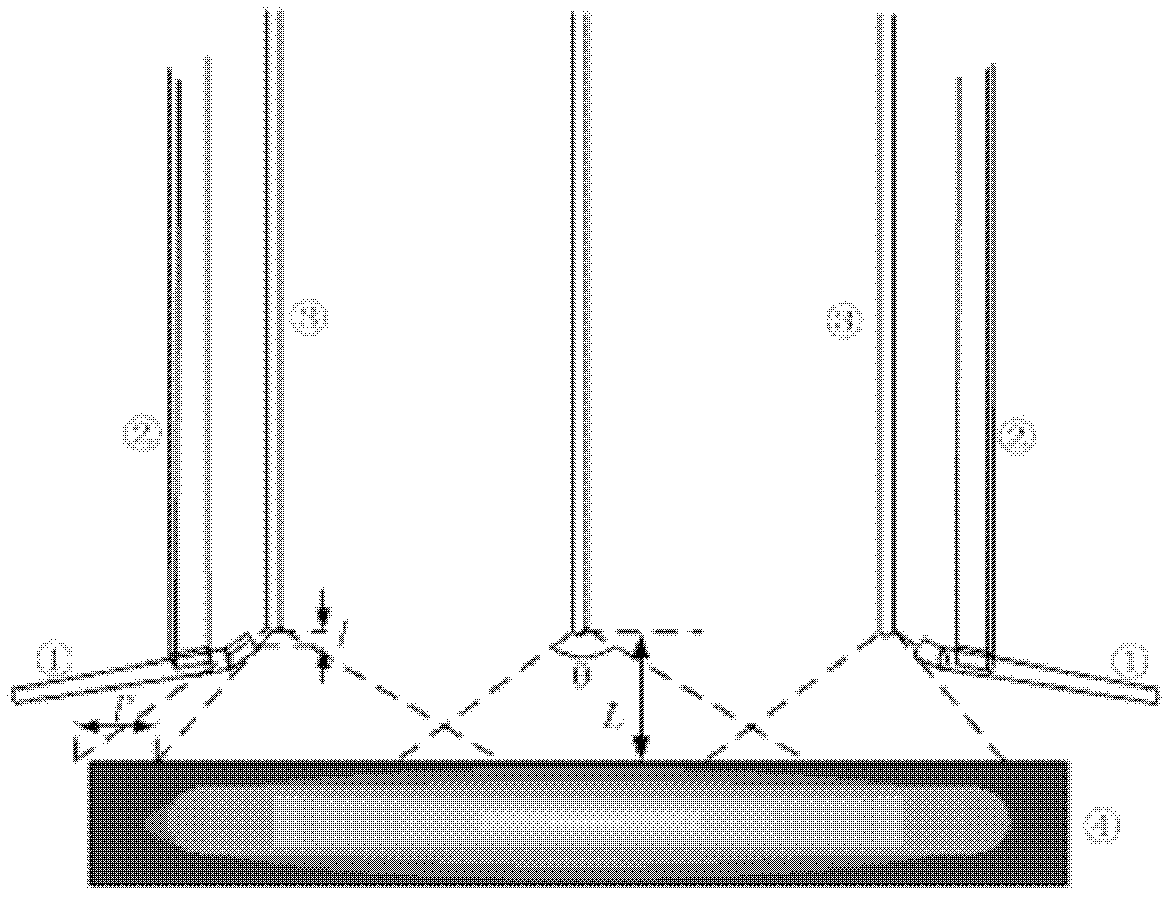

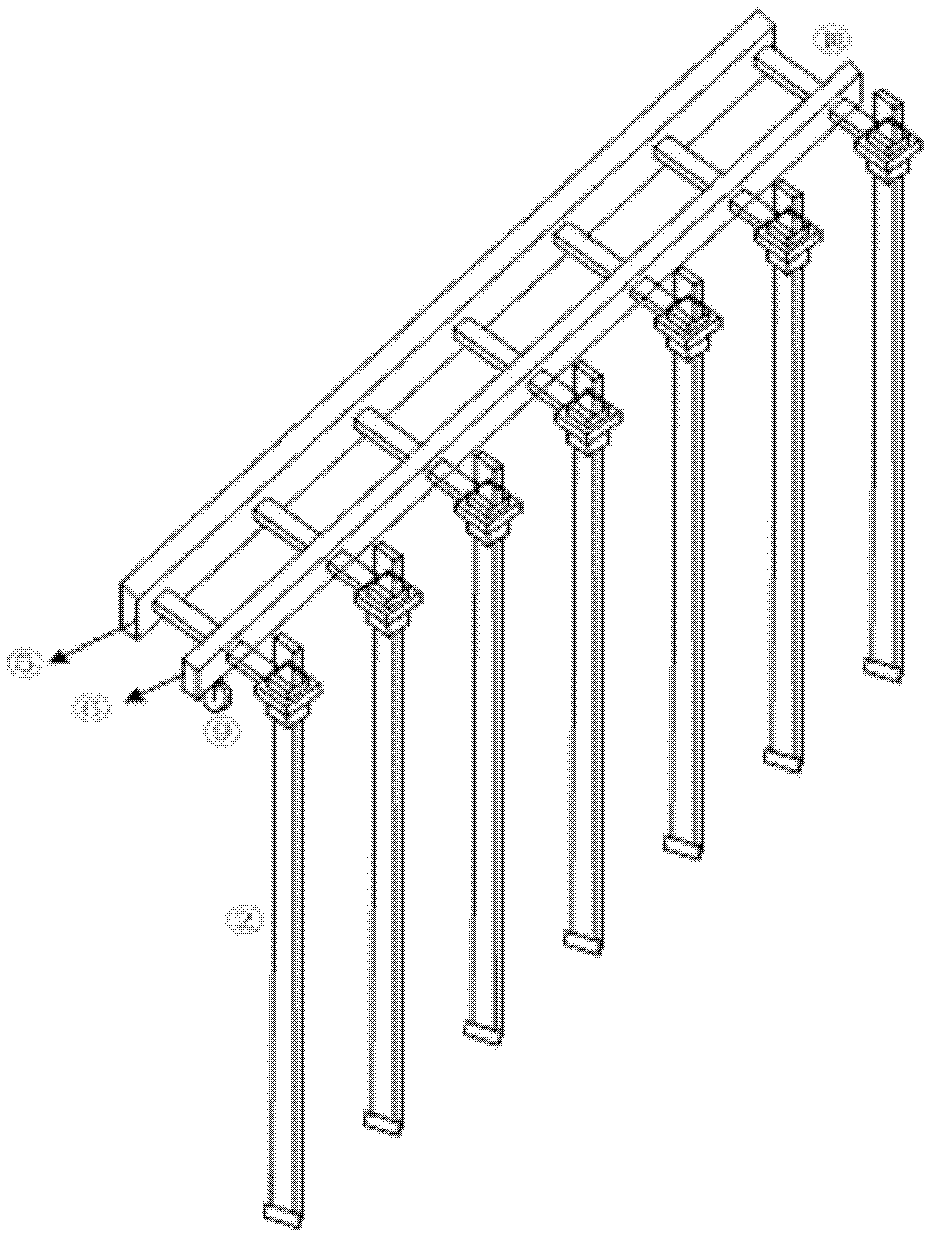

[0023] Continuous casting machine parameters: straight arc wide and thick slab continuous casting machine, 0 section is vertical bending section, 1-6 section is arc section, 7-8 section is straightening section, 9-14 section is horizontal section, streamline The total length is 35.5m; the cross-sectional width specifications of the slabs for production are 1600mm, 1800mm and 2100mm respectively, and each sector is equipped with 7 rows of spray pipes, and each row is equipped with 3 nozzles at equal intervals. The height of the nozzles from the upper surface of the slab is uniform is 480mm, the spray angle of the nozzle is 110°, and the original coverage width of the secondary cooling water in the transverse direction of the slab is 2470mm.

[0024] The specific parameters in the implementation of the present invention are: the second cold water spray width online automatic adjustment diversion device system is installed on both sides of the casting stream in the arc section 3-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com