An all-terrain four-wheel drive off-road vehicle chassis and its vehicle

An off-road vehicle and all-terrain technology, which is applied to vehicle components, elastic suspensions, suspensions, etc., can solve problems such as small bearing capacity and complex structure, and achieve the effect of enhancing the passing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

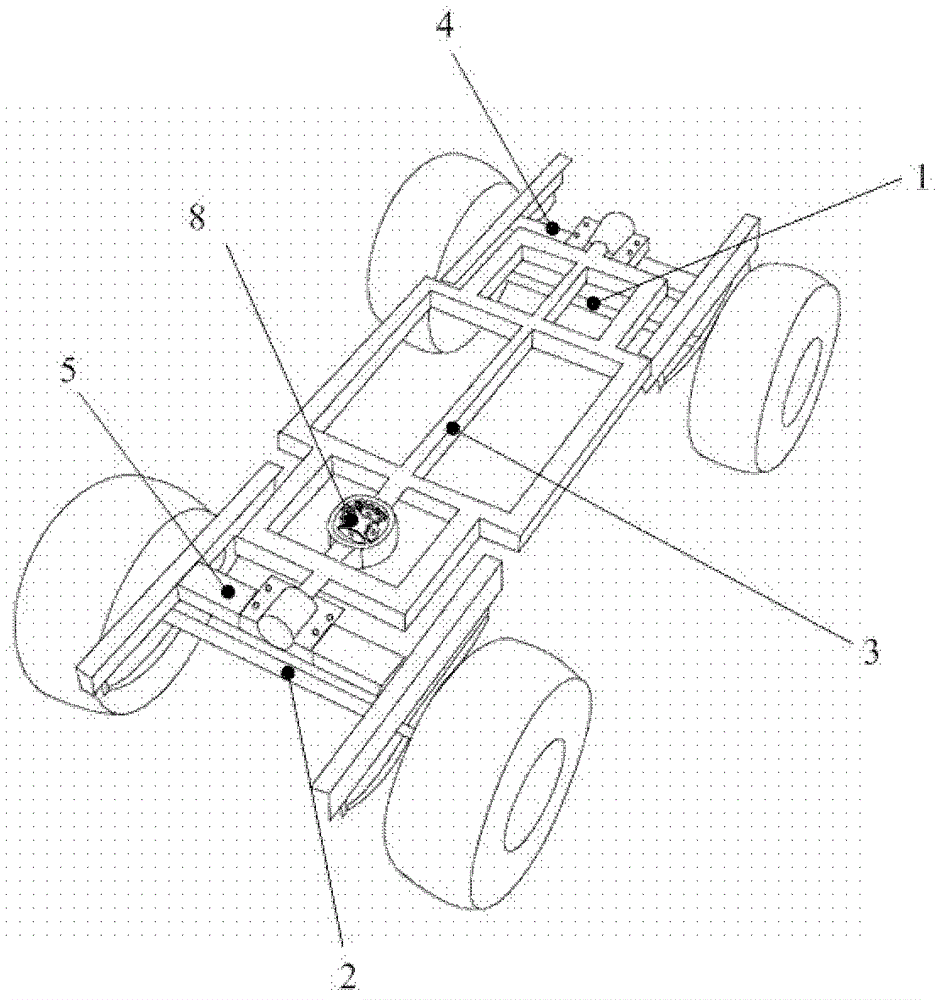

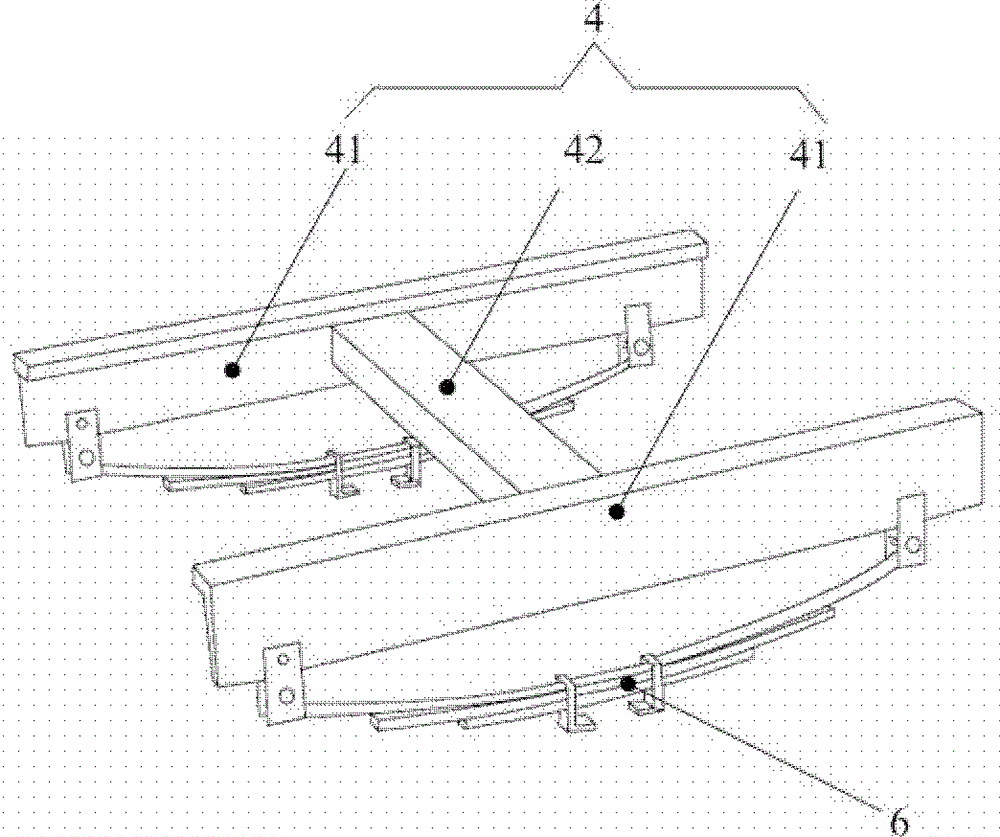

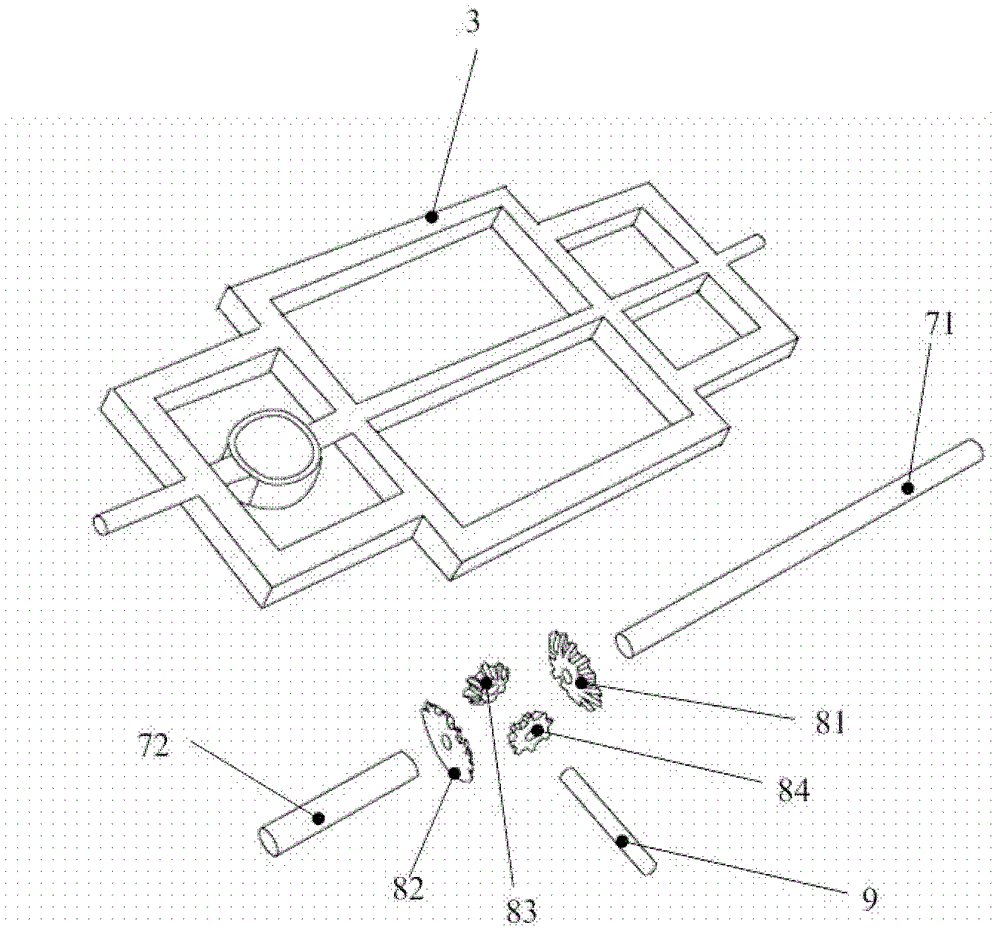

[0026] figure 1 It is a schematic diagram of the overall structure of an all-terrain four-wheel drive off-road vehicle chassis proposed by the present invention. figure 2 for figure 1 Schematic diagram of the structure of the I-beam. image 3 for figure 1 Schematic diagram of the local explosion structure of the all-terrain four-wheel drive off-road vehicle chassis.

[0027] refer to Figure 1-Figure 3 , the present invention provides an all-terrain four-wheel drive off-road vehicle chassis, comprising: a front axle 1, a rear axle 2, and a spine bridge 3 connecting the front and rear axles. The front axle 1 connects the two front wheels, and the rear axle 2 connects the two rear wheels. The spine bridge 3 is connected with the front axle 1 and the rear axle 2 through the first I-shaped swing frame 4 and the second I-shaped swing frame 5 respectively.

[0028] Wherein, the first I-shaped swinging frame 4 and the second I-shaped swinging frame 5 have the same structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com