Installation bracket of front steering lamp and front fairing

A front shroud and mounting bracket technology, which is applied in the field of motorcycle parts, can solve the problems of limited installation space, difficult management, and a large number of mounting bracket parts, and achieve the effects of beautiful assembly, reliable strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

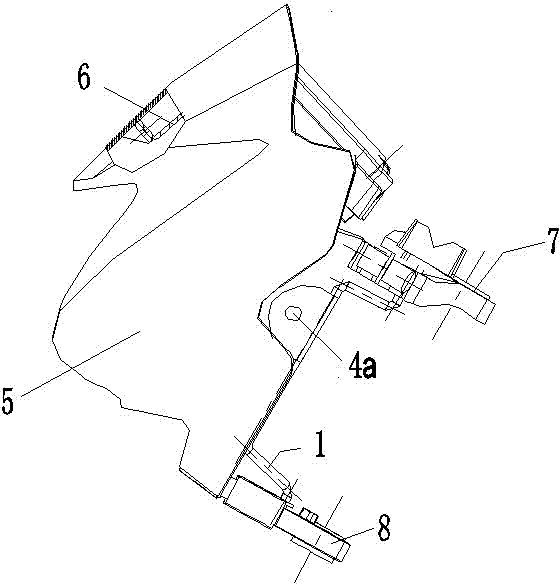

[0011] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

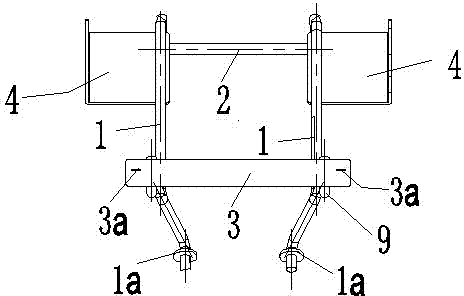

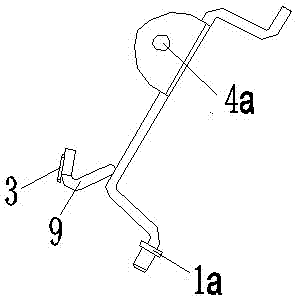

[0012] like figure 1 , figure 2 The mounting brackets of the front turn signal lamp and the front windshield shown are formed by welding the bending rod 1 , the first connecting rod 2 , the second connecting rod 9 , the first mounting plate 3 and the second mounting plate 4 . Two bending rods 1 are symmetrically arranged left and right, the middle part of the bending rod 1 is a straight rod, the upper part of the bending rod 1 is bent backwards and then upwards, and the lower part of the bending rod 1 is bent backwards and then downwards bent. The first connecting rod 2 is arranged at the middle and upper part of the two bending rods 1 , and the two ends of the first connecting rod 2 are respectively connected with the two bending rods 1 . The second connecting rod 9 is arranged on the middle and lower parts of the two bending rods 1, and the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com