Glass fiber reinforced plastic finned tube and production method

A pipeline and conveying pipeline technology, applied in the field of FRP reinforced pipes and production, can solve the problems of uneven product quality, low elongation at break, poor hoop stiffness, etc., and achieve high production efficiency, high corrosion resistance, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings. This manufacturing technology using long fiberglass fiber and the production technology of continuous drawing and weaving fiberglass reinforced pipe are relatively clear to those skilled in the art.

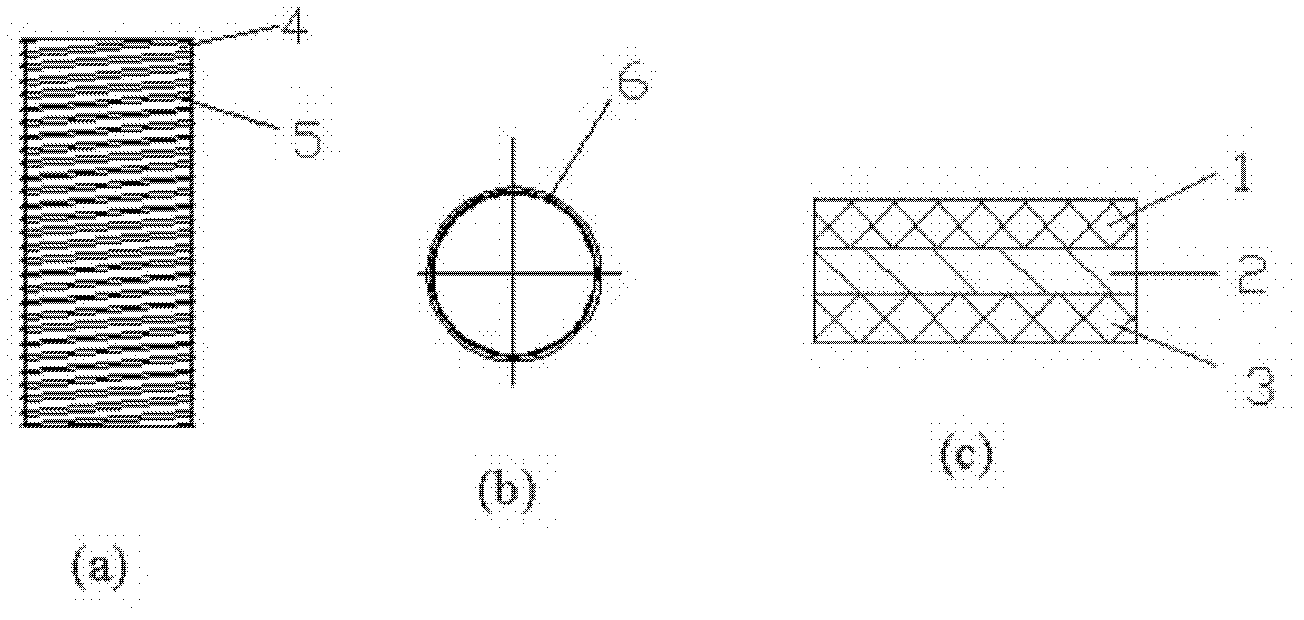

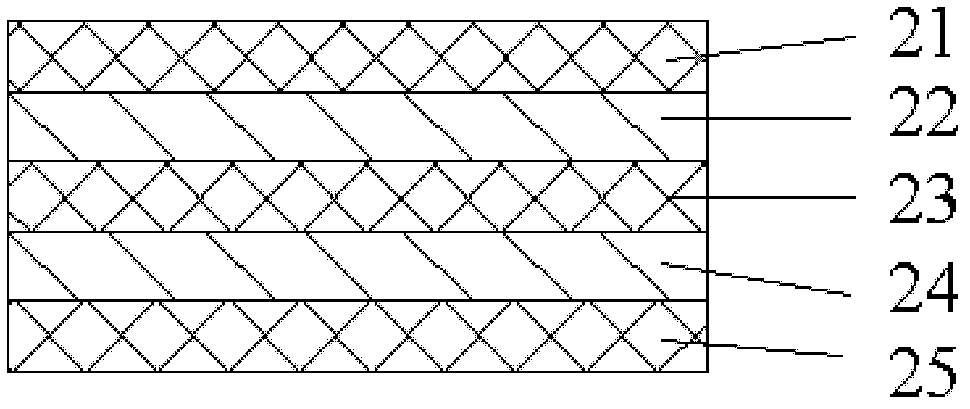

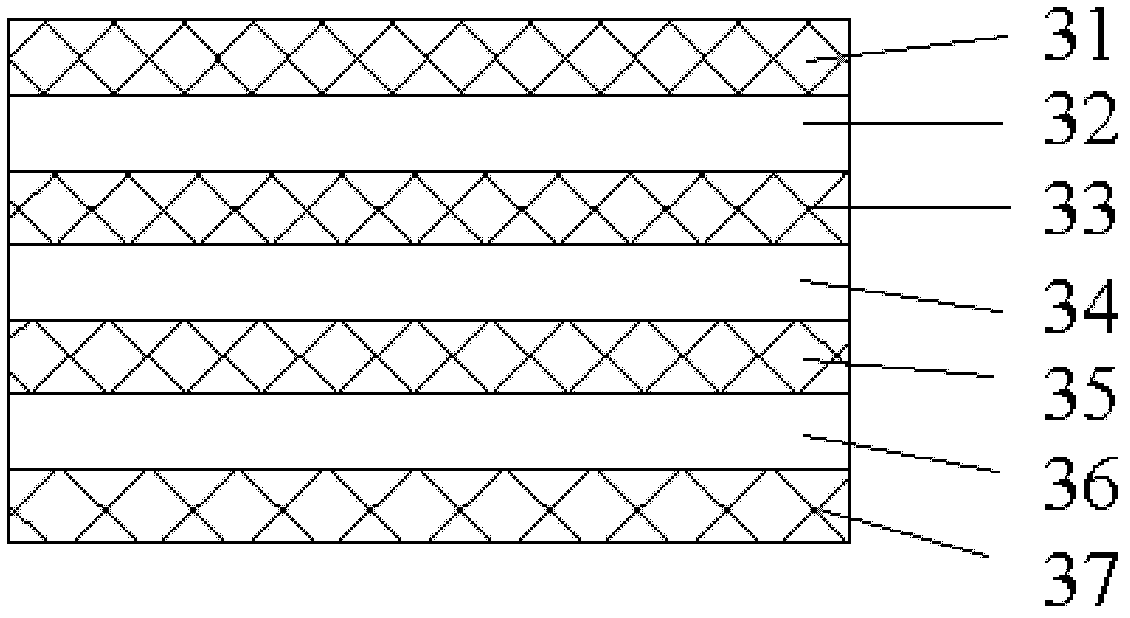

[0022] figure 1 The three-layer schematic diagram of the basic structure of the reinforced pipe is given, figure 2 A schematic diagram of the structure of a five-layer structure reinforced pipe is given, image 3 A schematic diagram of the structure of a seven-layer structure reinforced pipe is given,

[0023] refer to figure 1 According to the product design requirements, open the mold, heat up the mold, and prepare the weaving machine and fiber spindle, according to figure 1 or figure 2 or image 3 Weave the fiber layer, the fiber layer can be three layers, or multi-layer long fiber weaving, the fiber layer is covered on the mandrel and dipped in the dipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com