Continuous large-caliber woven fiber reinforced thermoset pultrusion pipeline and production method

A braided fiber and thermosetting technology, applied in the field of braided fiber reinforced thermosetting pultruded pipes, can solve the problems of low longitudinal strength, poor bottom strength, short life, etc., achieve high strength and rigidity and impact resistance, and overcome labor-intensive, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the accompanying drawings, the present invention will be described in further detail. This fiber layer weaving technology including the intermediate layer production technology is clear to those skilled in the art. The product structure and technical indicators of different production methods are different.

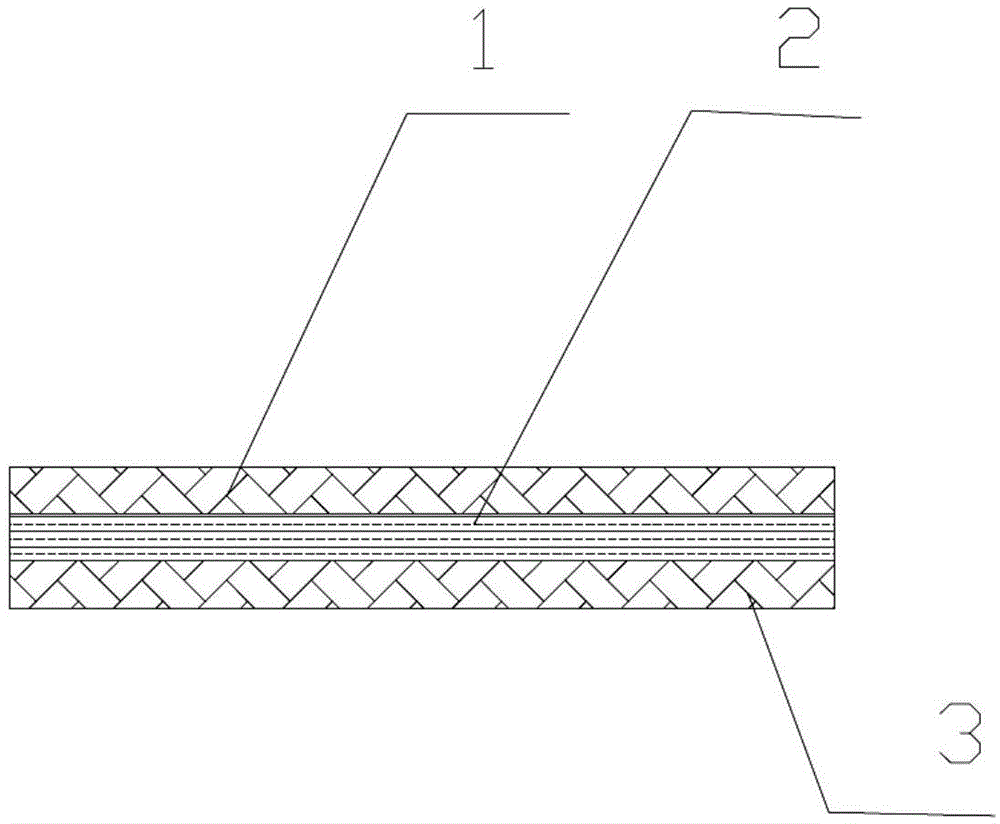

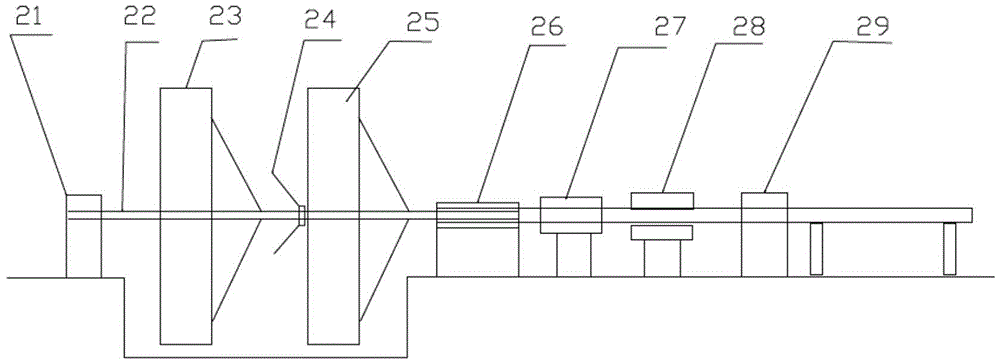

[0018] figure 1 The three-layer schematic diagram of the basic structure of the fiber braided layer is given, figure 2 A process flow diagram is given, see figure 2 , the mold 22 is fixed on the mold support 21, the outer mold 27 is heated up, and the braiding machine 23 and the braiding machine 25 and the fiber spindle and the intermediate layer 24 are ready, figure 1 The fiber layer is coated on the core mold 22 and dipped in the dipping mold 26, together with the intermediate fiber, it enters the outer mold 27 under the traction of the tractor 28, heats and solidifies, and the product comes out from the right end to a length of 6 met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com