Balance test mould and test method of flexible gyroscope inertia rotor component

A technology of balance testing and gyro rotor, applied in the field of manufacturing, can solve the problems of gyro drift, large dispersion, affecting the magnification of the test circuit, etc., to ensure the accuracy and repeatability, and improve the overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

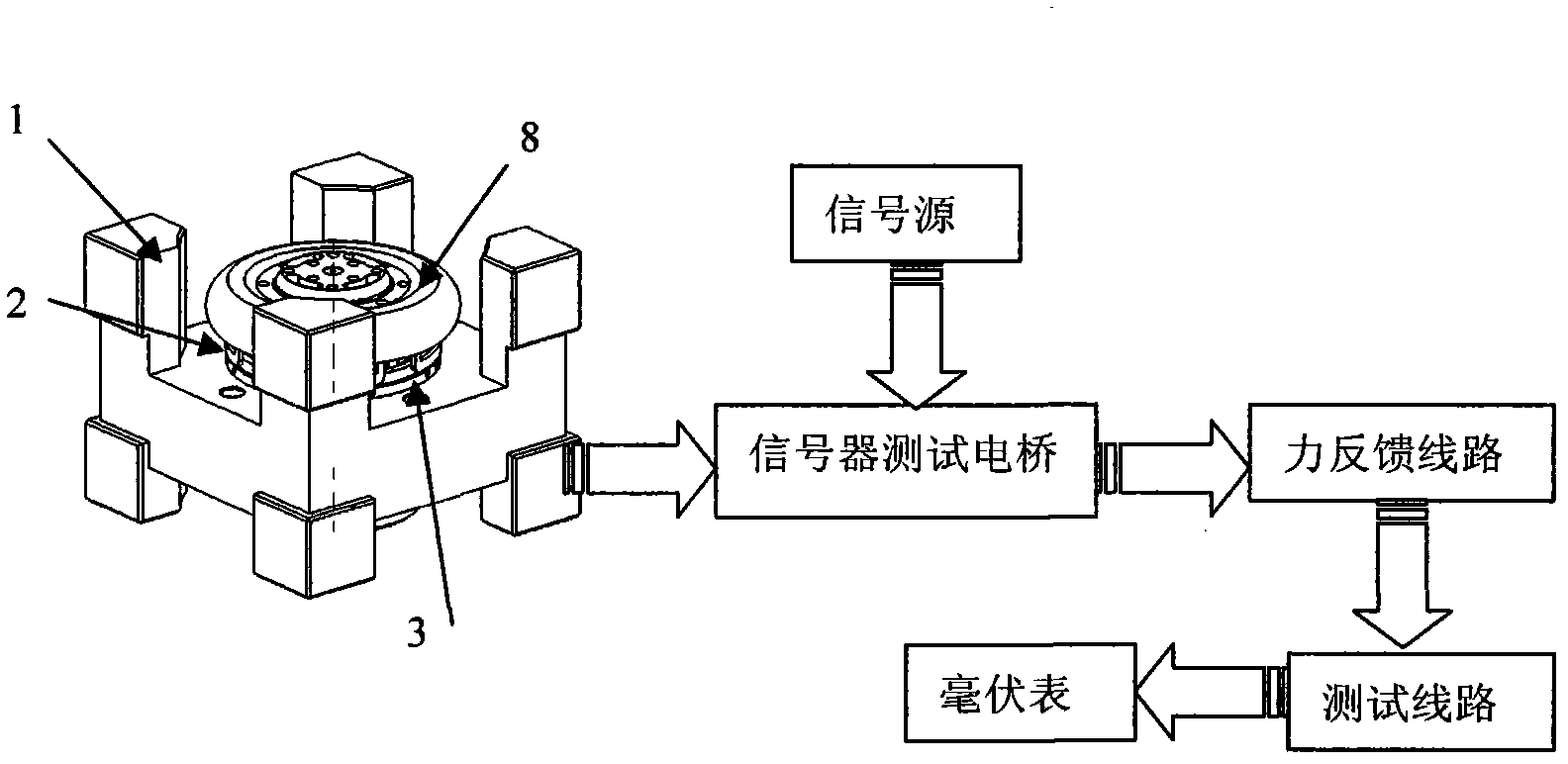

[0030] Such as figure 1 , the realization of this method mainly includes two parts: testing mold and measuring circuit system. The test mold provides a benchmark for the test and provides the function of adjusting the gap of the annunciator to be consistent; the measurement circuit system includes the annunciator test bridge, force feedback loop, etc., which are all flexible gyroscope testing general circuits, and the test instrument and power measurement system include the signal source (Model 33220A), dual-channel digital AC millivoltmeter (Model TH2290A) provides measurement power and test output.

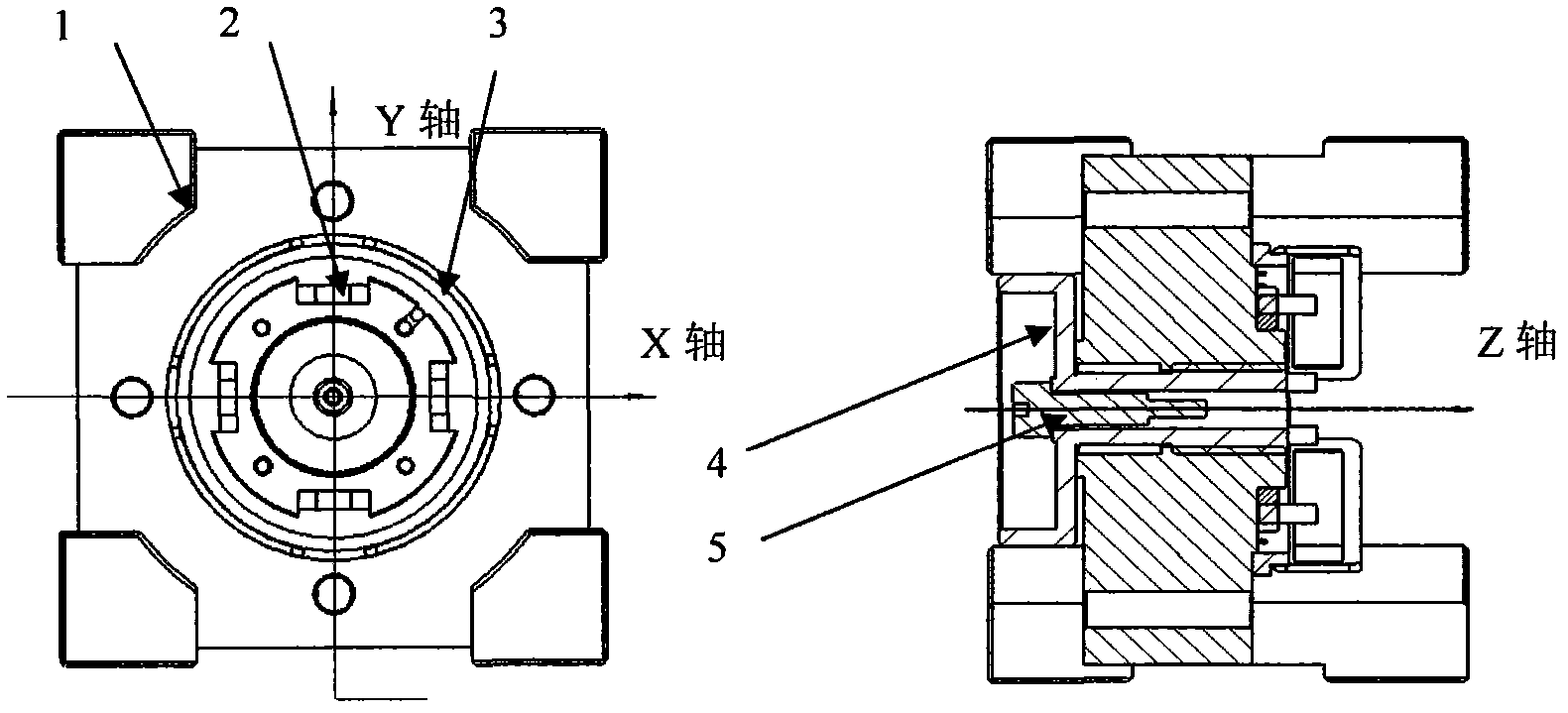

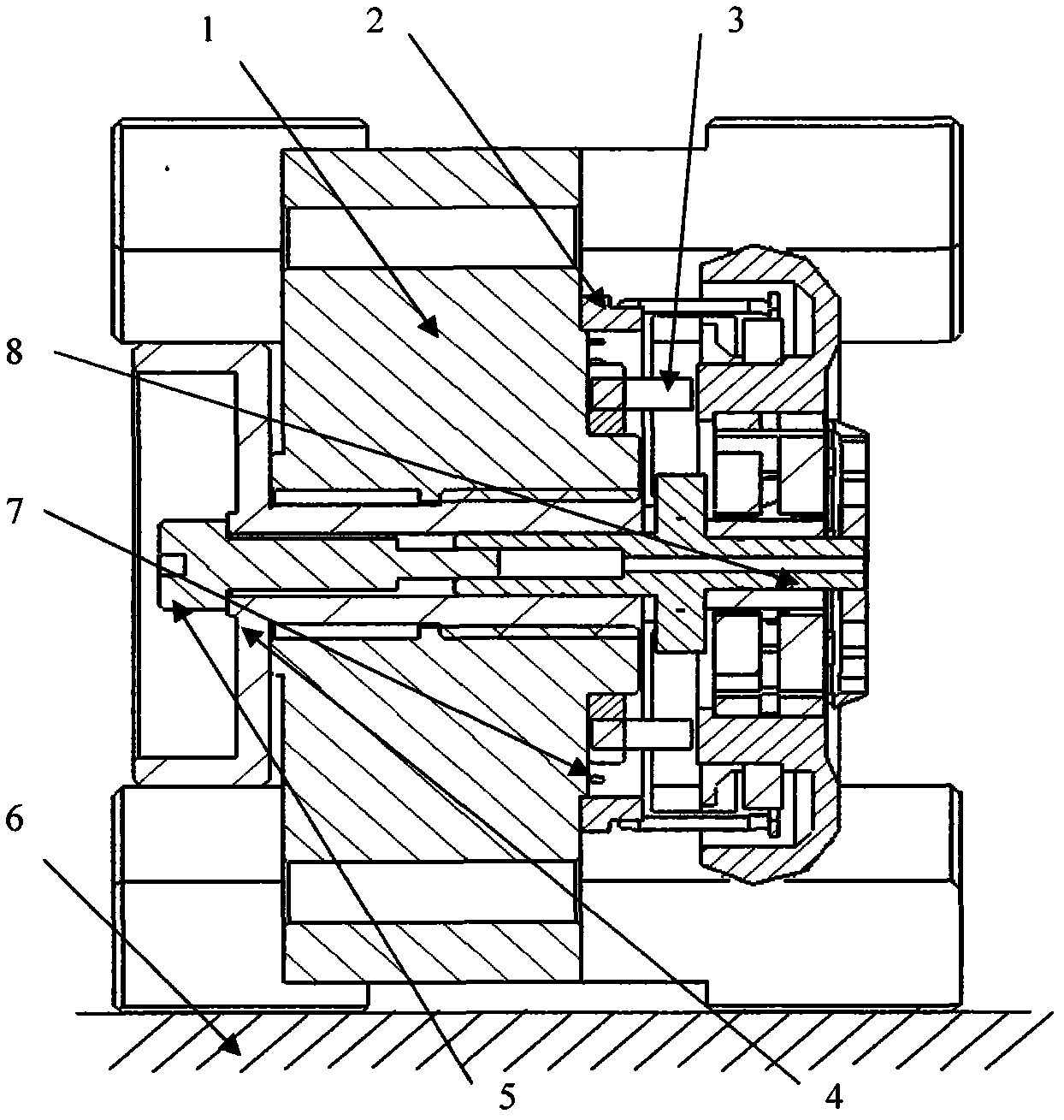

[0031] 1. Test mold

[0032] The static balance test of the gyro rotor includes two parts: the axial unbalance test and the radial unbalance test. The axial unbalance test process needs to test the gyro rotor under test at two positions of 0° and 180° when it is placed horizontally. The radial unbalance test process requires testing at two positions of 0° and 180° when the gyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com