Terminal device

A terminal unit and terminal technology, applied in the direction of electrical components, contact parts, coupling devices, etc., can solve the problem that the movement track of the unlocking handle is difficult to become stable, and achieve the effect of reliable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

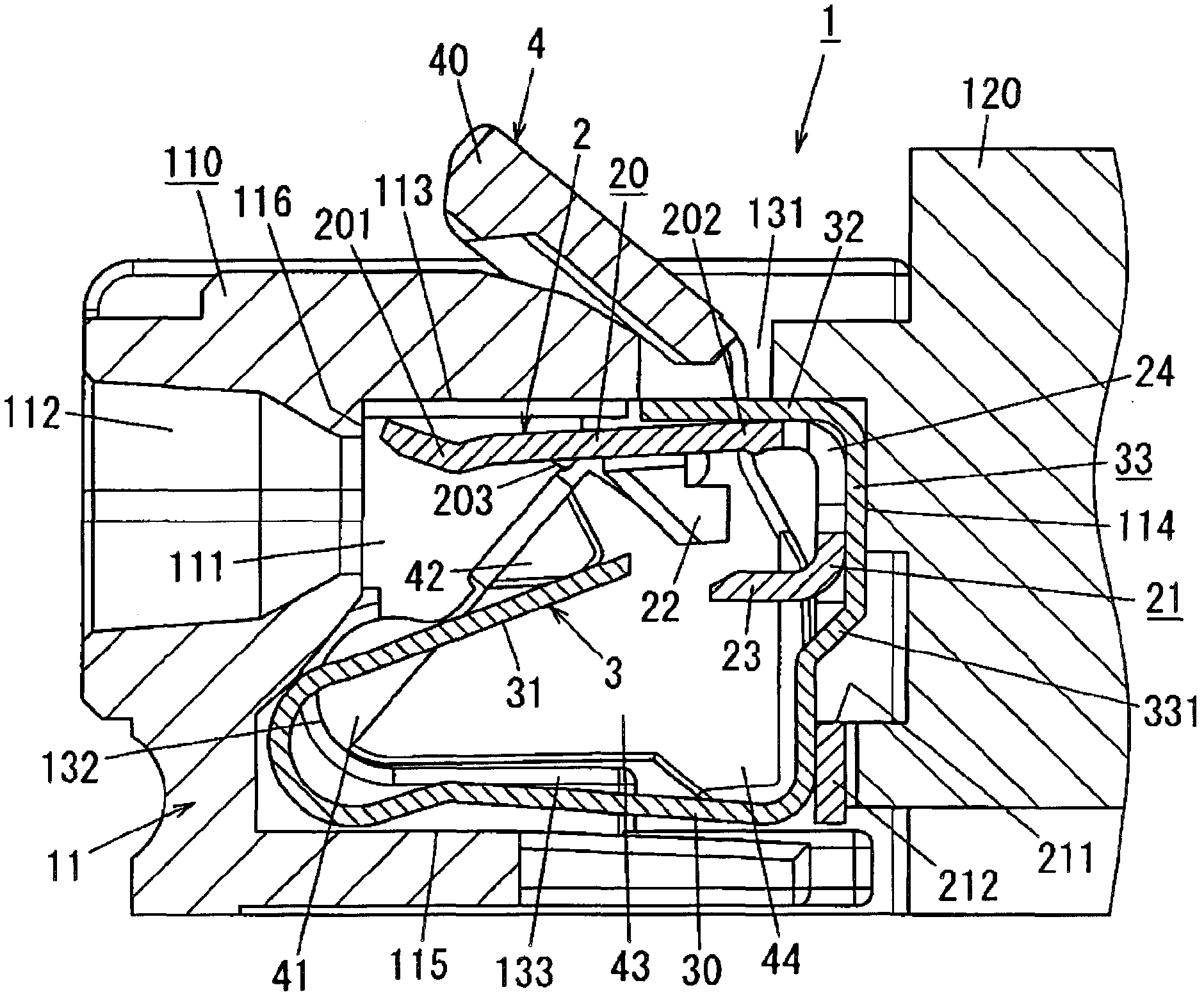

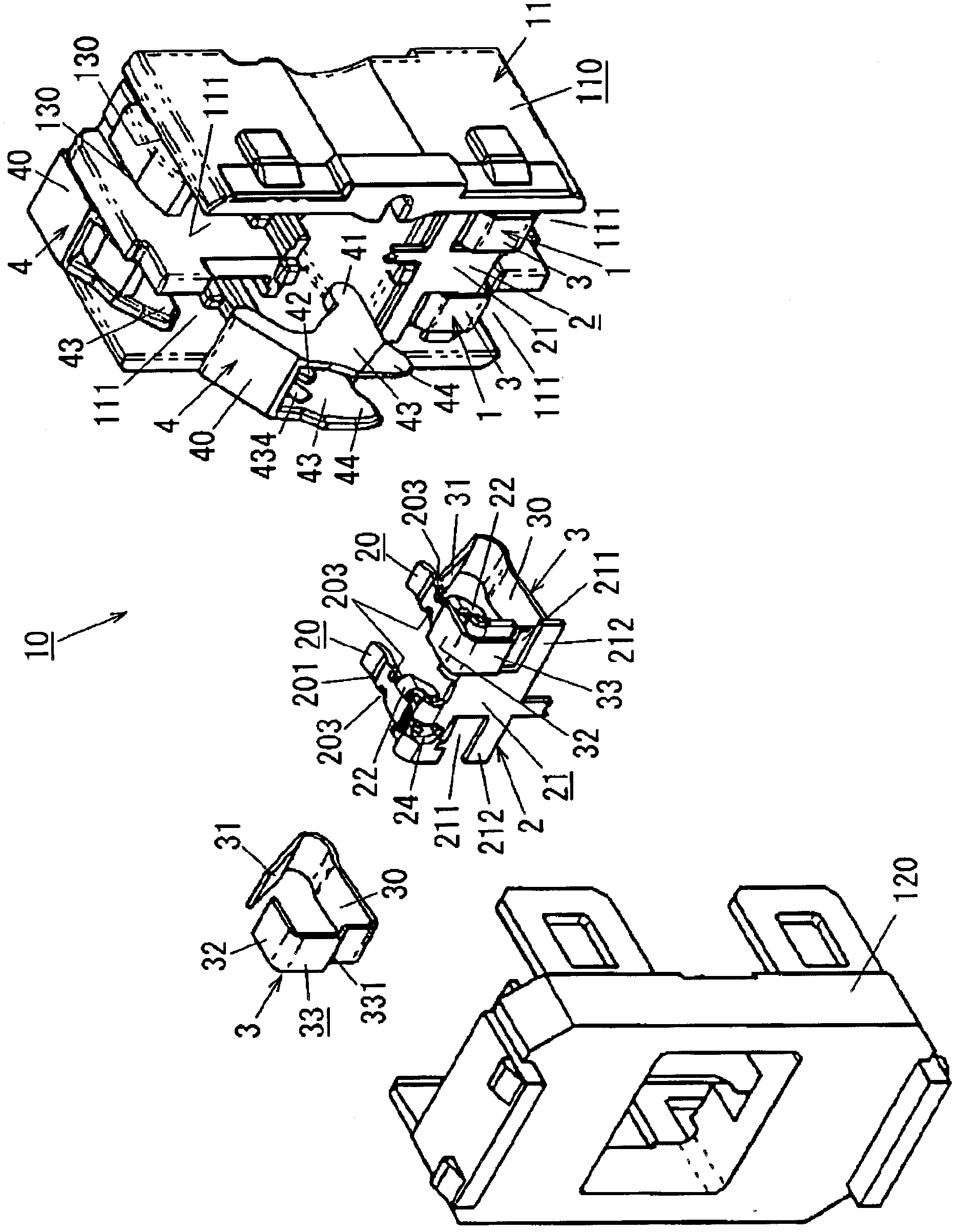

[0033] The terminal unit according to the present embodiment is equipped with, for example, figure 2 Embedded wiring device 10 is shown. In the following description, the up-down direction, front-back direction, and left-right direction are defined according to the state in which the wiring device 10 is attached to the wall (in figure 2 , the up-down direction is vertical, the lower-left side is forward and the upper-left side is left). However, these definitions are not intended to limit the orientation in which the terminal unit may be used.

[0034] Such as figure 2 The illustrated wiring device 10 includes a device housing 11 made of synthetic resin. The device case 11 includes a rectangular box-shaped body 110 having a front opening, and a cover 120 combined with the body 110 to cover the opening of the body 110 .

[0035] A pair of storage chambers 111 arranged side by side in a lateral direction (left-right direction) are formed in each longitudinal (vertical) op...

no. 2 example

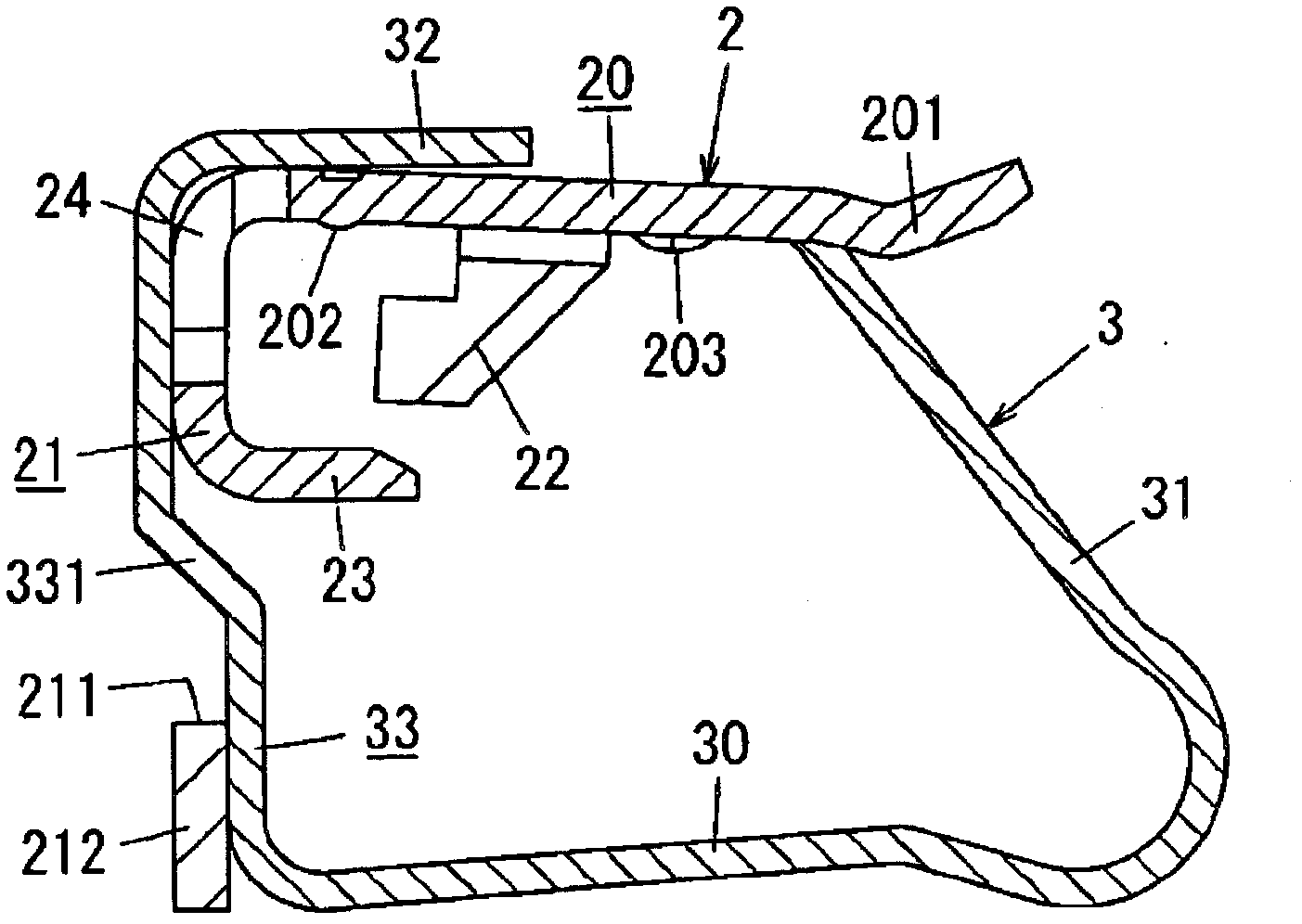

[0087] The terminal unit 1 of the present embodiment is fitted to an outlet as a wiring device. The terminal unit 1 of this embodiment differs from the terminal unit 1 of the first embodiment in that Figure 8 Protrusions 213 are formed in the clamping tab 21 of the illustrated end plate 2 .

[0088]The protrusion 213 is formed on a clamping surface 214 which is one thickness direction surface (front surface) of the clamping piece 21 . The protrusions 213 are arranged between the insertion grooves 211 of the clamping pieces 21, and have a circular shape as seen in plan view. The protrusion 213 protrudes forward from the clamping surface 214 . The protruding dimension of the protrusion 213 is set to be greater than the thickness of the connecting piece 33 of the lock spring 3 . In other words, the height of the protrusion 213 from the clamping surface 214 is set to be greater than the height of the connecting piece 33 of the lock spring 3 from the clamping surface 214 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com