Cable railway system

A technology for cableways and cable cars, applied in the field of cableway systems, can solve problems such as increased wear of support rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

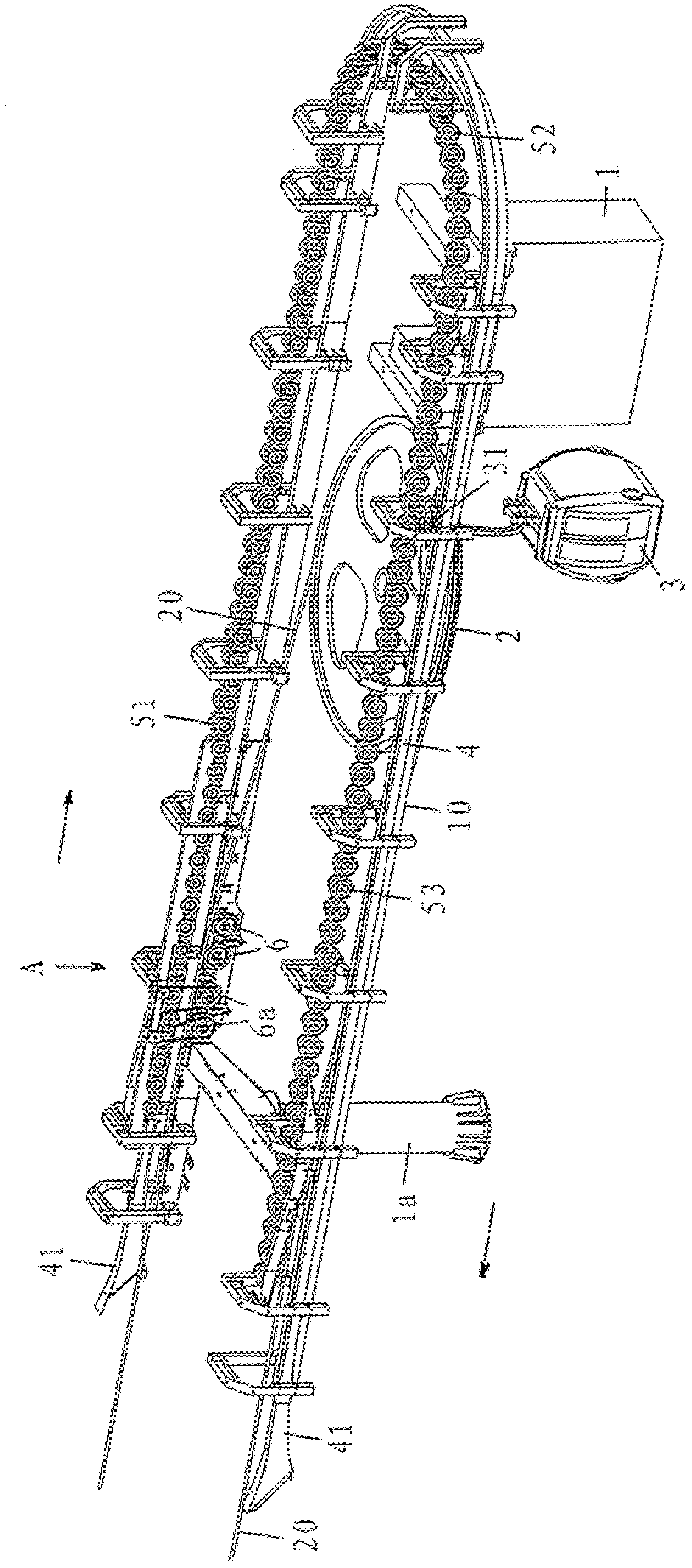

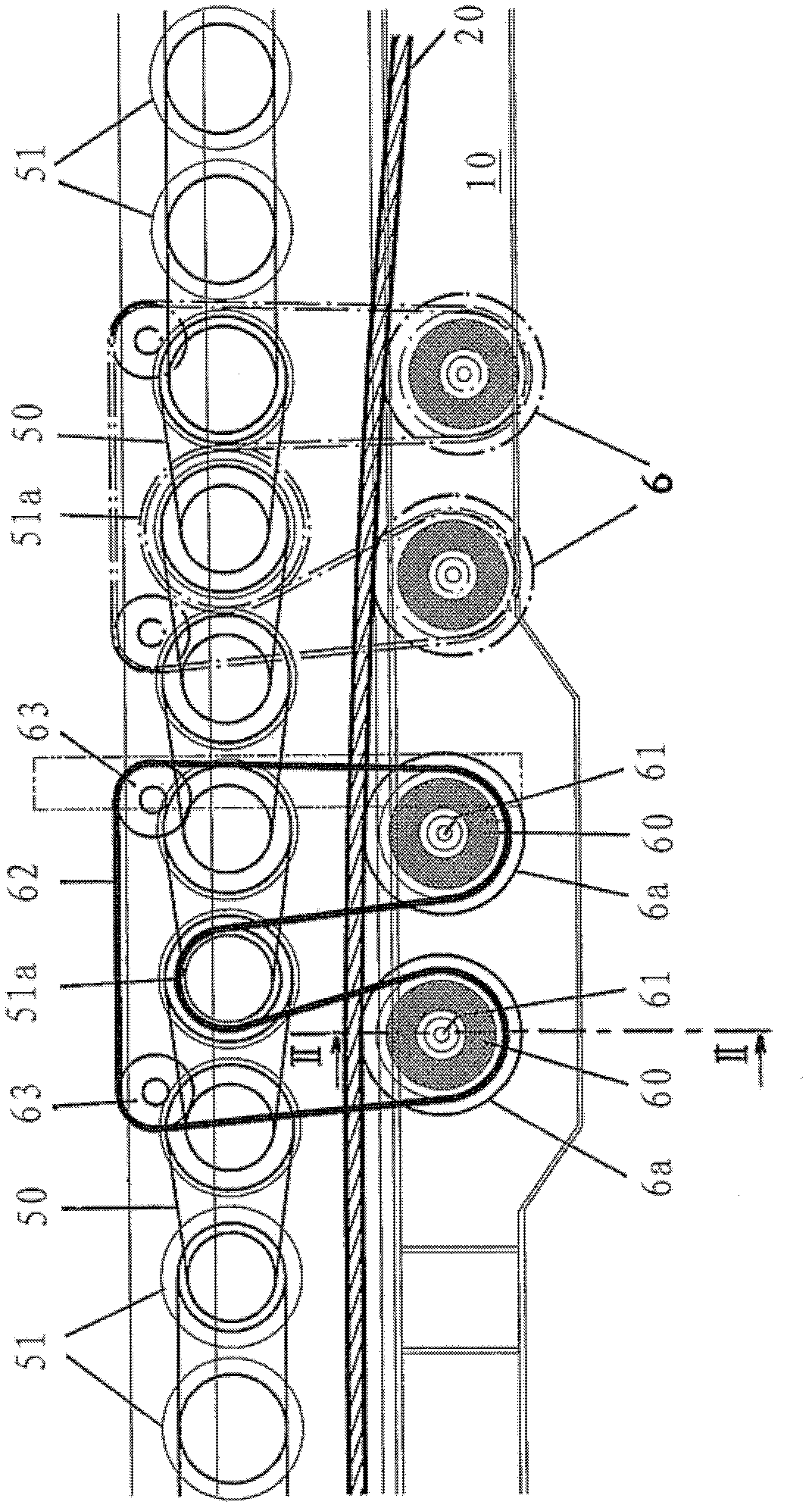

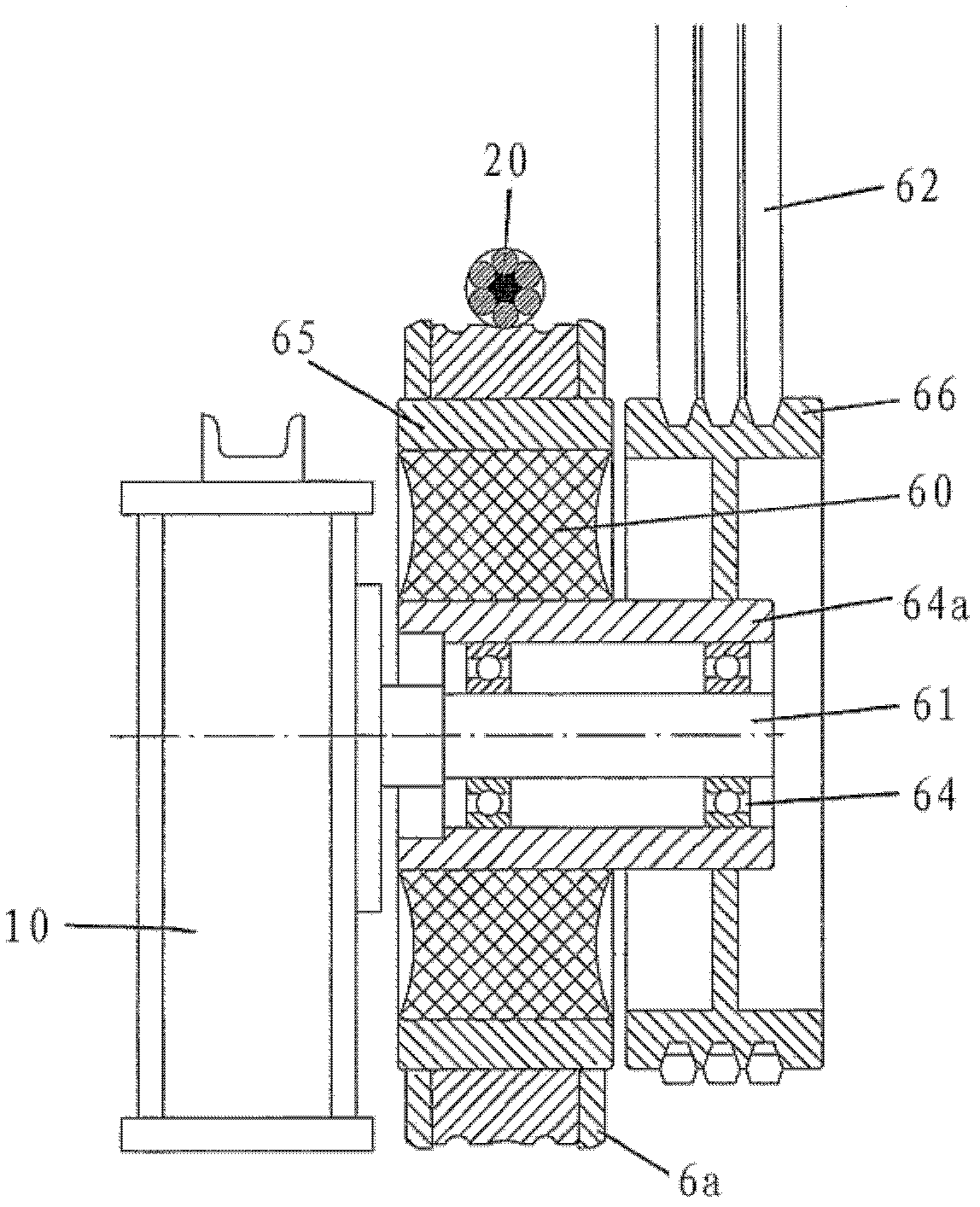

[0022] Reference is now made to the figure numbers of the accompanying drawings in detail and first in particular to figure 1 , which shows a terminal station with a load supporting structure 10 supported by columns 1 and 1a and on which a deflection pulley 2, also called a head wheel, is mounted on an approximately vertical axle , is guided via the pulley transmission cable 20 . During operation of the funicular cableway system, the transmission cable 20 is run at a speed of eg 6 m / s by means of a drive motor located preferably at the top station. The transport vehicle 3 , in the present case the gondola, can be connected to the transmission cable 20 . On the road, the motor vehicle 3 is connected to the transmission cable 20 . At the entrance to the station, the motor vehicle 3 is detached from the transmission cable 20 and moved through the station along the guide rail 4 by means of a running transmission 31 . At the exit of the station, the vehicle 3 is reconnected to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap