Drill bit

A drill bit and sub-face technology, applied in twist drills, drill accessories, drilling/drilling equipment, etc., can solve problems such as drill bit breakage, and achieve the effect of large cutting angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

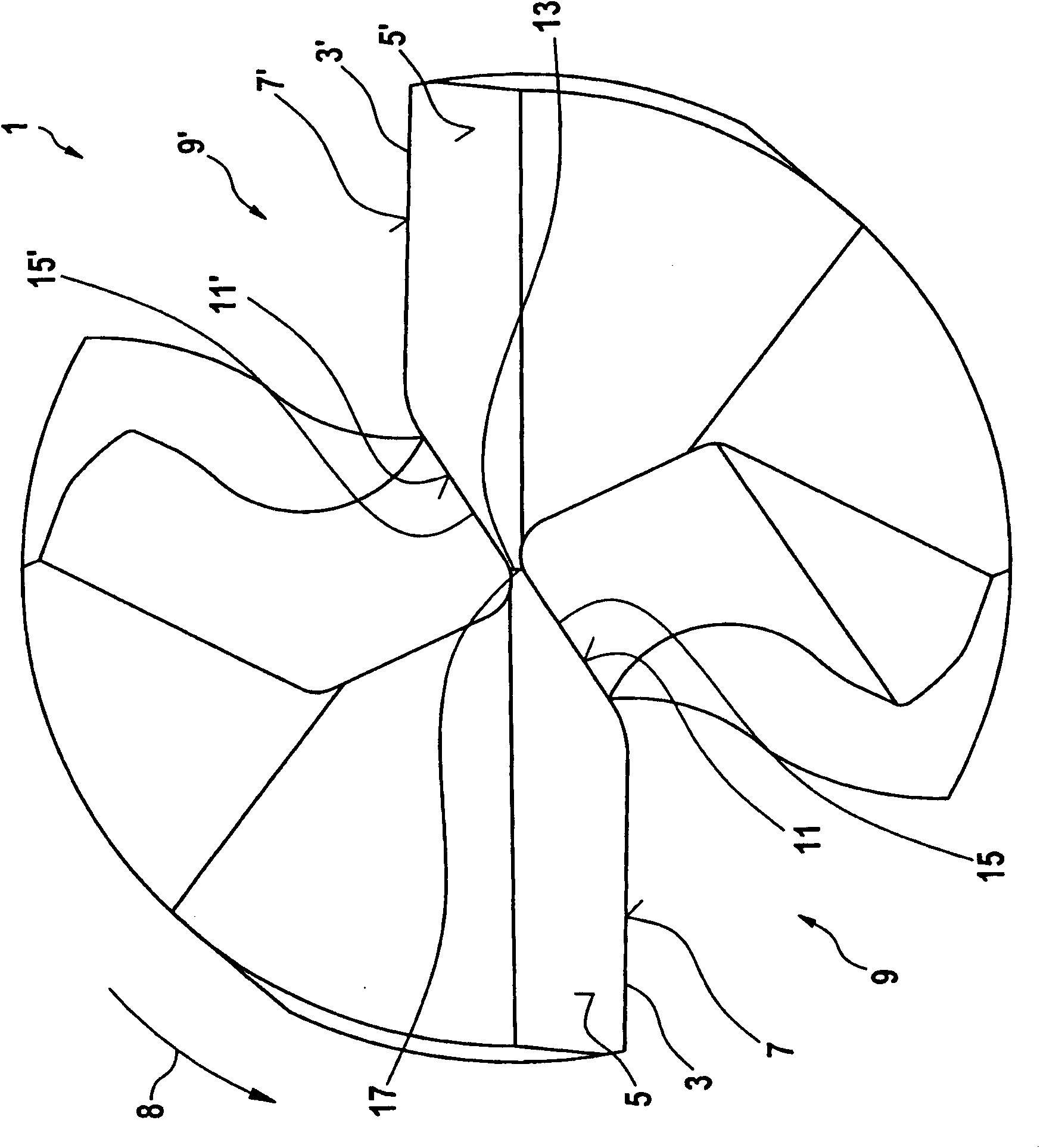

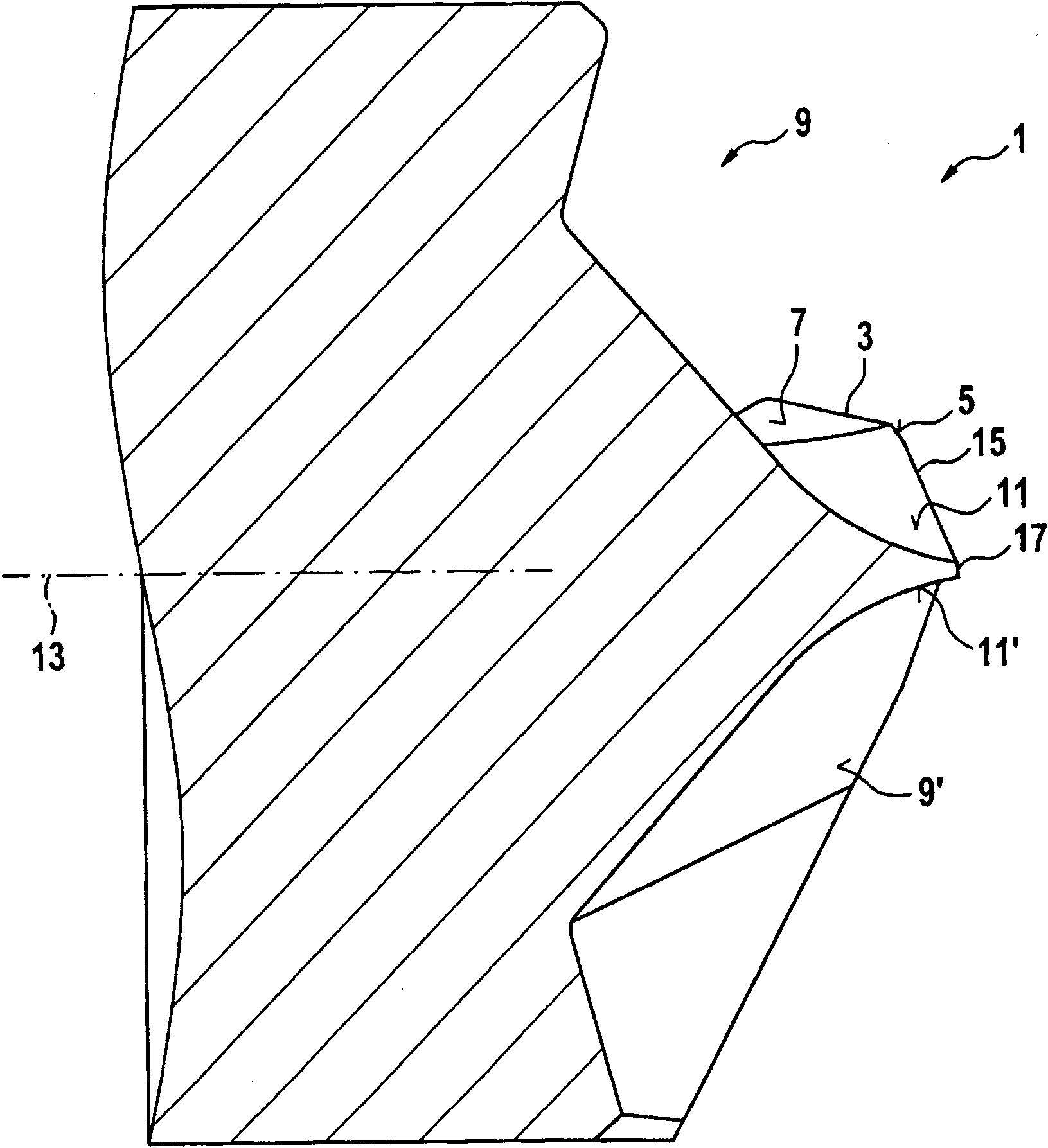

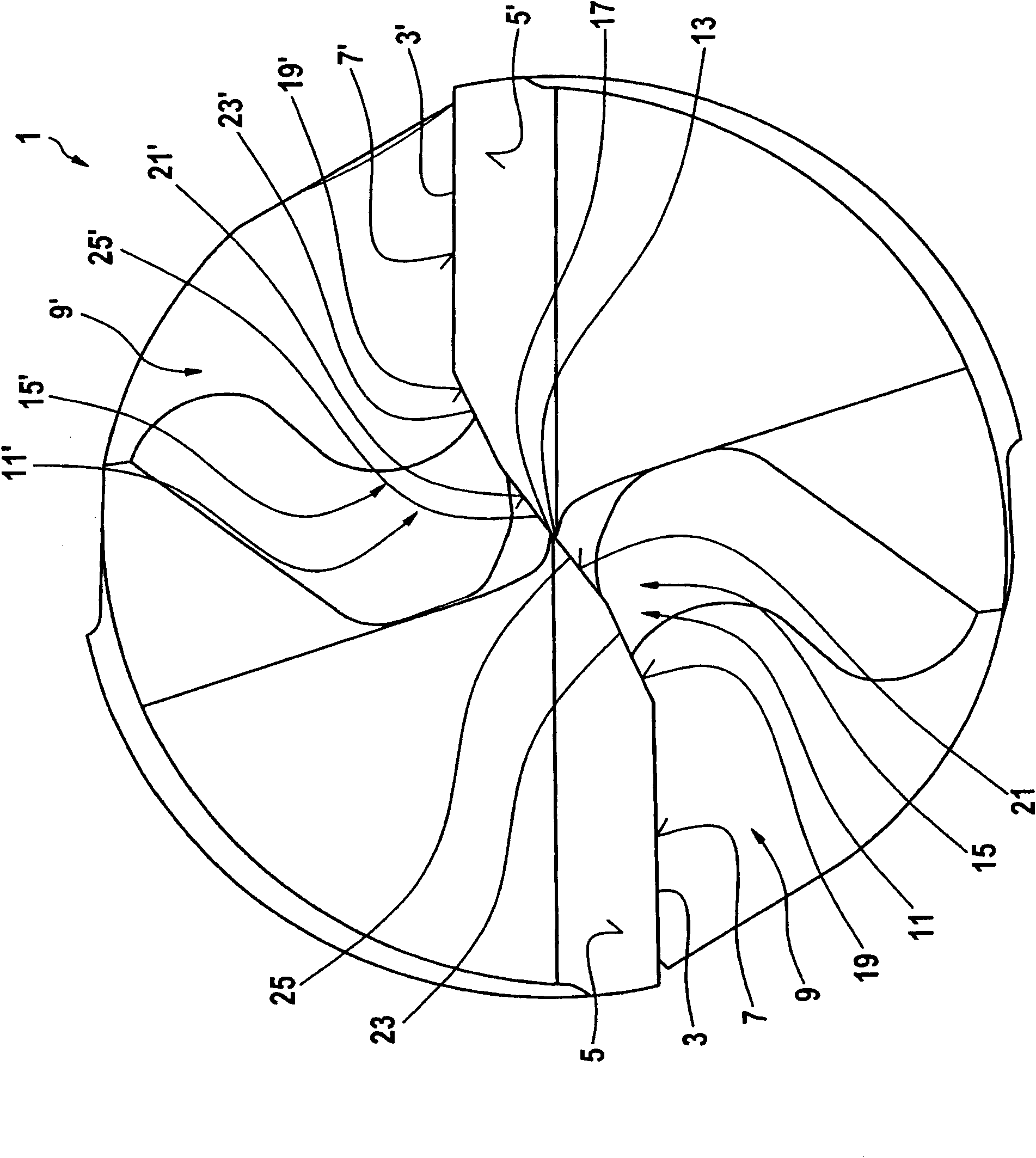

[0023] figure 1 A front view of a known drill bit 1 is shown, which has a conventional geometry with sharpening. The drill comprises at least one main cutting edge, to be precise here two main cutting edges 3 and 3'. The main cutting edges 3 and 3' are each formed by the intersection of the free surface 5, 5' and the cutting surface 7, 7'. The free faces 5 , 5 ′ follow the main cutting edges 3 and 3 ′ in the cutting direction, which here means the direction of rotation of the drill when machining the workpiece. In this embodiment, this direction is opposite to the clockwise direction and is indicated by arrow 8 . The free surfaces 5 , 5 ′ fall opposite to the cutting direction so that they form an angle with a plane parallel to the machined surface of the workpiece, which is referred to as the free angle (Freiwinkel). The chips removed from the workpiece by the main cutting edges 3 and 3' are discharged from the cutting faces 7, 7'. The cutting faces 7, 7' form an angle wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com