Assembly and method for manufacturing a green radial pneumatic tyre

A technology of pneumatic tires and radials, which is applied in the field of manufacturing green radial tires, and can solve the problems of cord path pattern obstruction, conventional path destruction, rubber layer deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

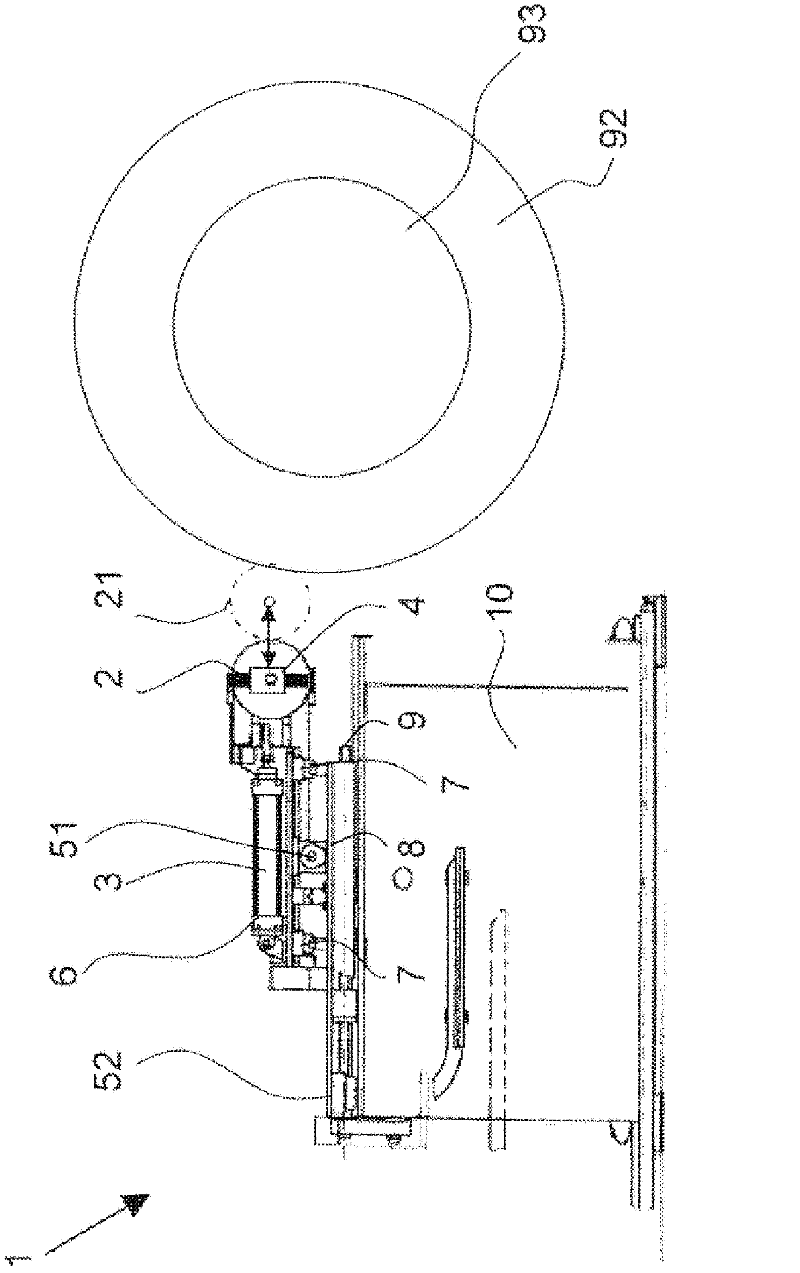

[0036] The tire drum 93 is used to be built on or unrolled on a carcass 92 having beads and sidewalls when green radial pneumatic tires are manufactured. After the crown / carcass has been placed on the carcass 92, the crown / carcass is pressed against the carcass 92 with beading, sidewalls and crown / casing by means of the pressing roller unit 1 with an adjustable force , while rotating the drums 93 so that they are attached to each other for forming an embryonic radial tire which can then be further processed.

[0037] The pressing roller unit 1 can be composed of at least one such as figure 1The composition of the stitching roller 2 is shown schematically. Using the cylinders 3, the stitching roller 2 can be moved upwards in the direction of the tire drum 93 into the position 21 for pressing against the crown / carcass, and this position is shown in dotted lines. Subsequently, the stitching roller 2 is pressed against the carcass 92 with an adjustable force.

[0038] By means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com