Insert-molded product

A molding product, polycarbonate resin technology, applied in the direction of synthetic resin layered products, layered products, vehicle parts, etc., can solve problems such as insufficient fluidity of molding resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] The following were used as the functional resin film. Use a mixed solution of ethyl acetate / methyl ethyl ketone / isopropanol at a ratio of 2:2:1 to prepare "NT-HILAMIC" (registered trademark) 701R produced by Dainichi Seika Industry Co., Ltd. to a printing viscosity of 15 seconds ( Viscosity Cup Zahn Cup#3), the acrylic base film was pattern-printed by gravure printing method, dried in an oven at 70° C. for 10 seconds, and a 35 μm decorative layer was provided.

[0181] The polycarbonate resin for base materials was produced by the following method.

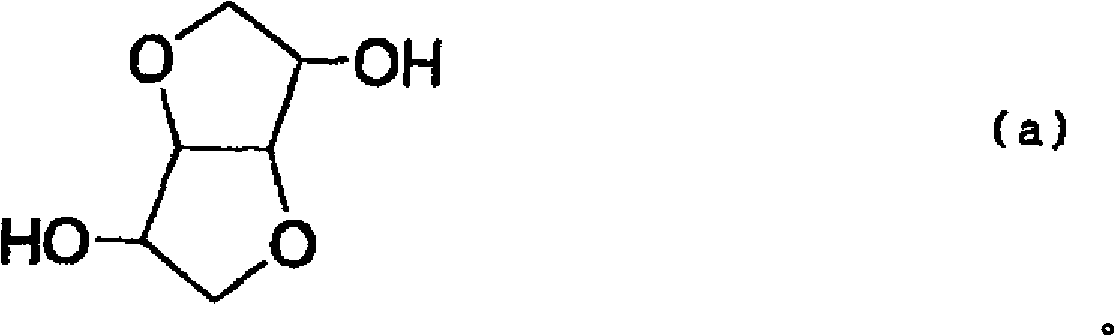

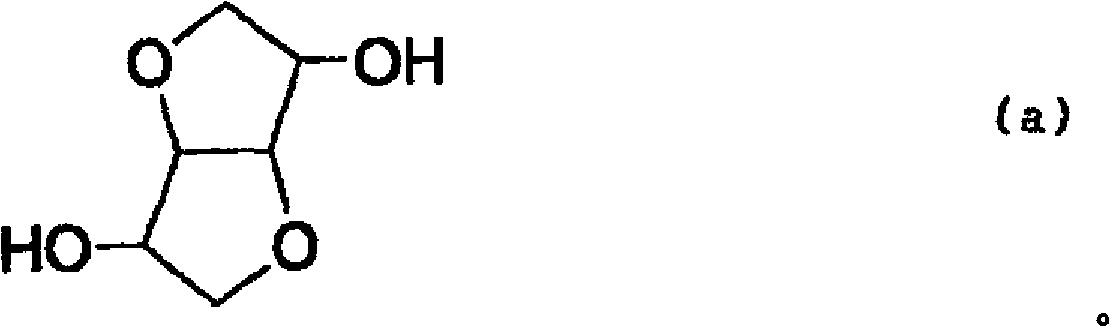

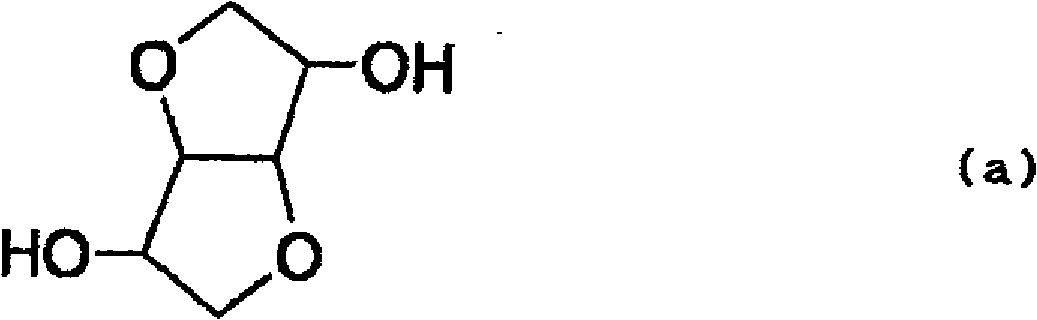

[0182] Add 1,608 parts by weight (11 moles) of isosorbide (hereinafter referred to as ISS sometimes) and 2,356 parts by weight (11 moles) of diphenyl carbonate, and add 1.0 parts by weight of tetramethylammonium hydroxide (relative to carbonic acid 1 mole of diphenyl ester component is 1×10 -4 mol) and sodium hydroxide 1.1×10 -3 Parts by weight (relative to 1 mole of diphenyl carbonate component is 0.25×10 -6 mol) was f...

Embodiment 2

[0193] 66.42 parts by weight of isosorbide (0.45 mole), 11.52 parts by weight (0.15 mole) of 1,3-propanediol (hereinafter referred to as PD) and 129.81 parts by weight (0.61 mole) of diphenyl carbonate are added in the reactor, and 1.0 parts by weight of tetramethylammonium hydroxide (1×10 with respect to 1 mole of diphenyl carbonate component -4 mol) and sodium hydroxide 1.1×10 -3 Parts by weight (relative to 1 mole of diphenyl carbonate component is 0.25×10 -6 mol) as a polymerization catalyst, the same test as in Example 1 was carried out to perform melt polymerization of the polycarbonate resin. The obtained polymer had a specific viscosity of 0.25, a glass transition temperature of 116°C, and a 5% weight loss temperature of 338°C. In the same manner as in Example 1, this resin was used as a molding material, and an insert-molded article with the functional resin film was produced and evaluated.

Embodiment 3

[0195] 804 parts by weight (5.5 moles) of isosorbide, 1,256 parts by weight (5.5 moles) of bisphenol A (BPA) and 2,356 parts by weight (11 moles) of diphenyl carbonate were added to the reaction tank, and tetramethylammonium hydroxide 1.0 parts by weight (relative to 1 mole of diphenyl carbonate component is 1×10 -4 mol) and sodium hydroxide 1.1×10 -3 Parts by weight (relative to 1 mole of diphenyl carbonate component is 0.25×10 -6 mol) was used as a polymerization catalyst, and the same operation as in Example 1 was performed to perform melt polymerization of the polycarbonate resin. The obtained polymer had a specific viscosity of 0.35, a glass transition temperature of 153°C, and a 5% weight loss temperature of 366°C.

[0196] In the same manner as in Example 1, this resin was used as a molding material, and an insert-molded article with the functional resin film was produced and evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com