Continuous steel wall and method for constructing same

A construction method and continuous wall technology, which can be used in excavation, artificial islands, water conservancy projects, etc., and can solve problems such as increased section performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

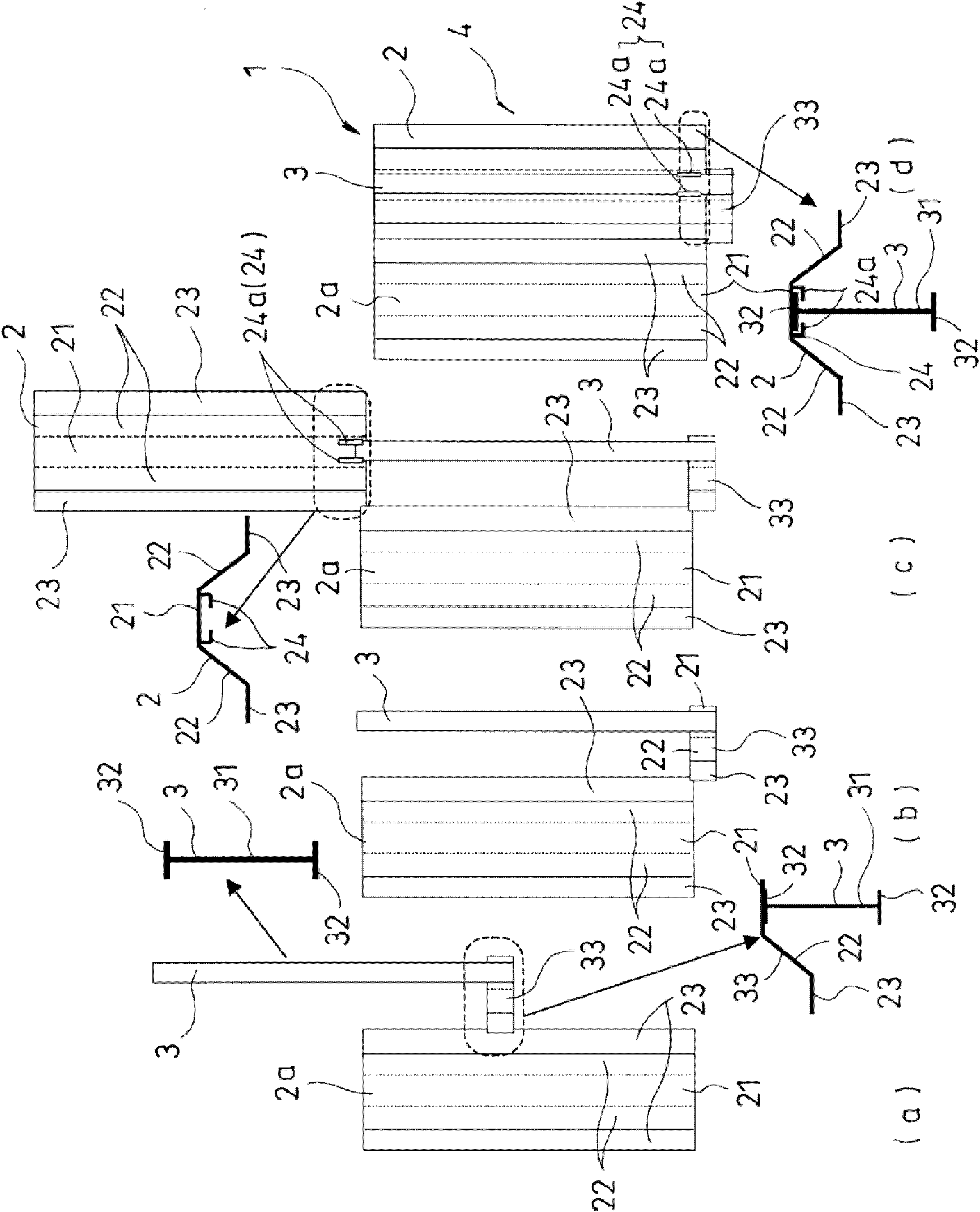

[0042] Embodiments of the present invention will be described below with reference to the drawings.

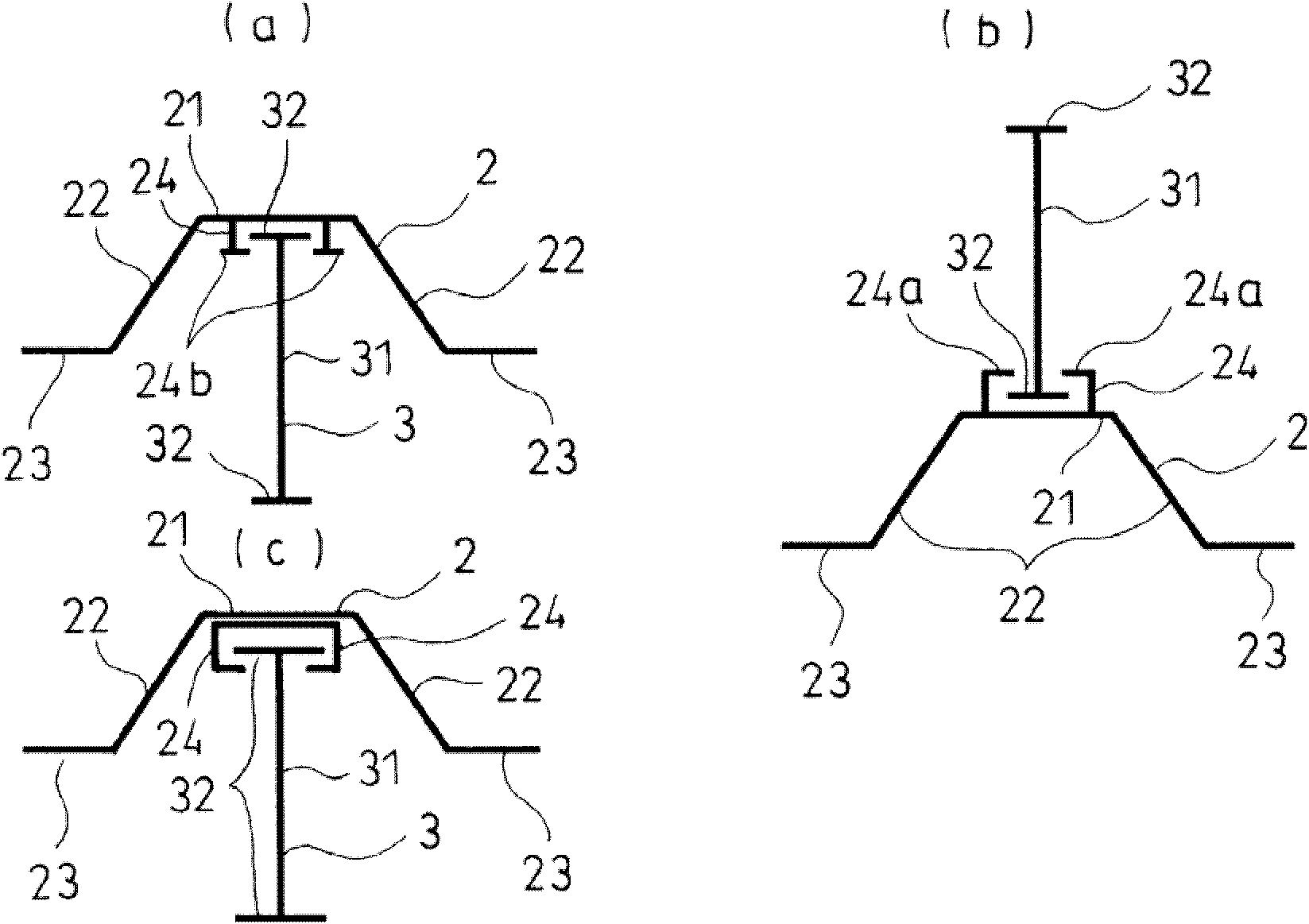

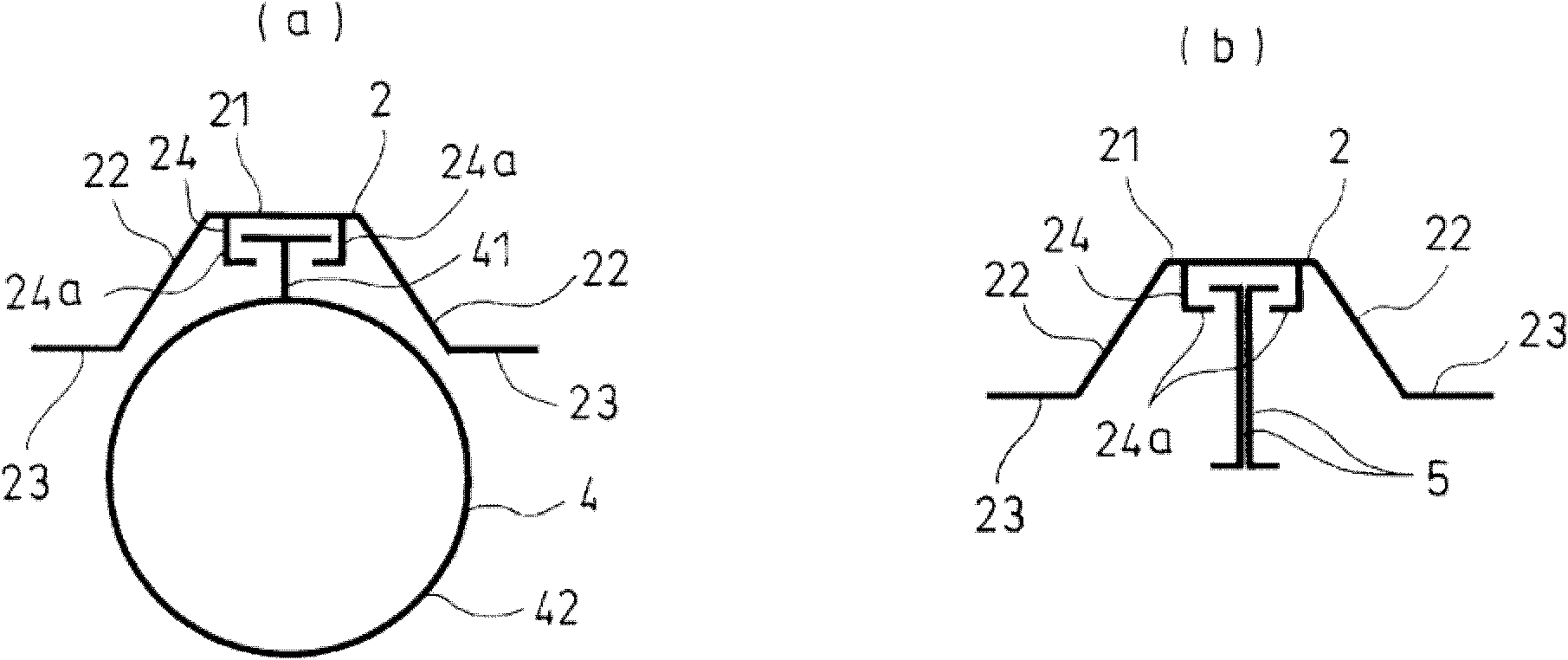

[0043] figure 1 The steel continuous wall 1 shown has the structure which contacted the steel sheet pile 2 and the H-shaped steel 3, without joining the hat-shaped steel sheet pile 2 and the H-shaped steel 3 which are reinforcements integrally.

[0044] As is well known, the hat-shaped steel sheet pile 2 includes a web 21 , flanges 22 provided obliquely so that the front ends of the web 21 extend from the left and right ends of the web 21 , and the front ends of the flanges 22 are parallel to the web 21 . The arm 23 extending ground and the joint (not shown) provided at the front end portion of the arm 23 . In addition, the joint is, for example, a well-known structure in which it is bent and folded back at intervals on the inner peripheral side. In addition, the left and right joints are folded back in opposite directions, and the opposite joints are fitted together.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com