Low-insertion-force connector

A low insertion force, connector technology, applied in the direction of connection, connecting device parts, coupling device, etc., can solve the problem of connector fitting and detachment, reduce rotation operation gap, promote gap saving, and promote compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

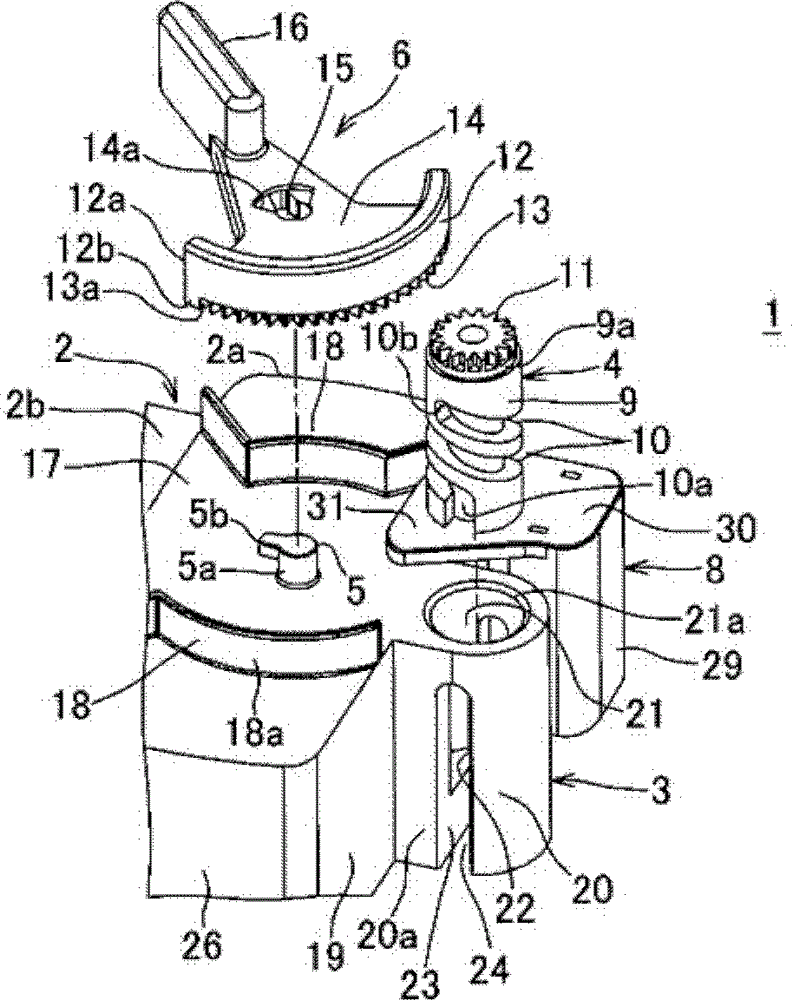

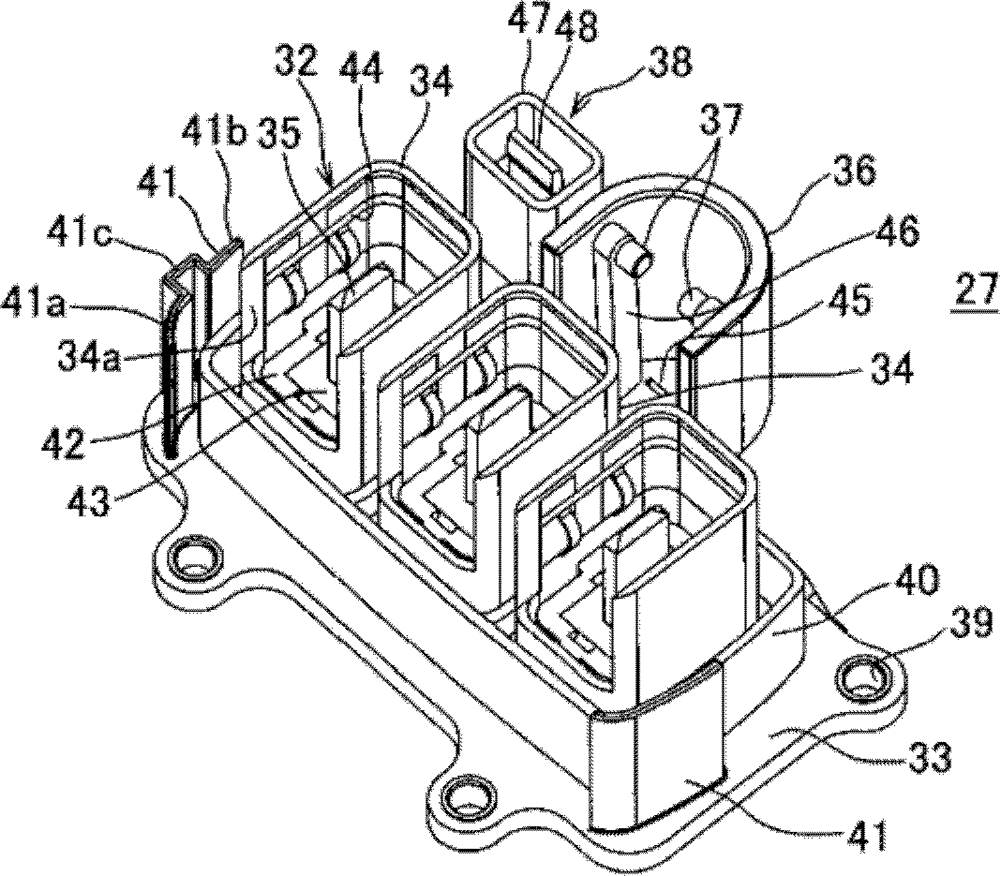

[0044] Figure 1 ~ Figure 2 It is a figure which shows the 1st Embodiment of the low insertion force connector concerning this invention. figure 1 Indicates the connector (female connector) that accommodates the female terminal, figure 2 It shows the other connector (male connector) that accommodates the male terminal, and two connectors constitute a low insertion force connector.

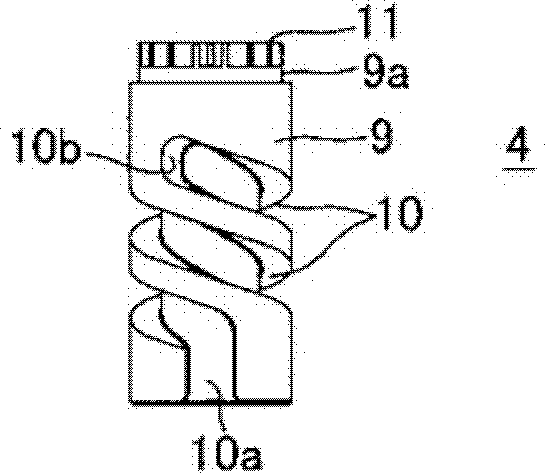

[0045] Such as figure 1 As shown, one connector 1 includes a connector housing 2 made of insulating resin and an L-shaped female terminal with a wire (not shown) housed in the connector housing 2 and is mounted on the connector housing 2. The cylindrical gear member 4 made of synthetic resin in the substantially cylindrical receiving portion 3, the drive rod 6 made of synthetic resin that is rotatably engaged with the shaft portion 5 of the connector housing 2 and meshes with the gear member 4, With the rail part 7 ( Figure 4 ) A safety circuit unit 8 that is slidably engaged and can be slidably mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com