Power transmission line steel tube tower and construction method thereof

A technology for transmission lines and steel pipe towers, which is applied to the spatial arrangement/configuration of towers and cables, building types, etc., can solve problems such as the impact of reliability data, and achieve reduction of construction personnel and labor, short external power outages, and input lines. The effect of less hardware material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical implementation process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

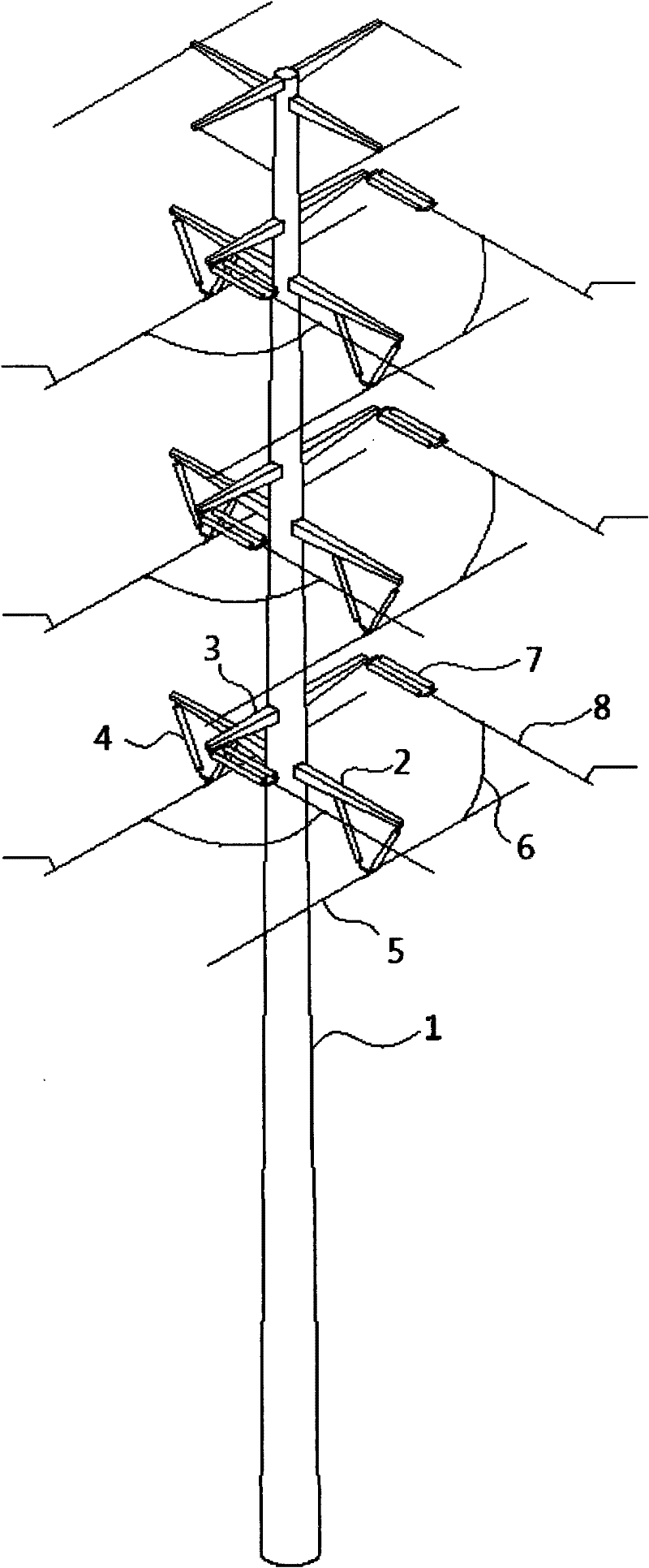

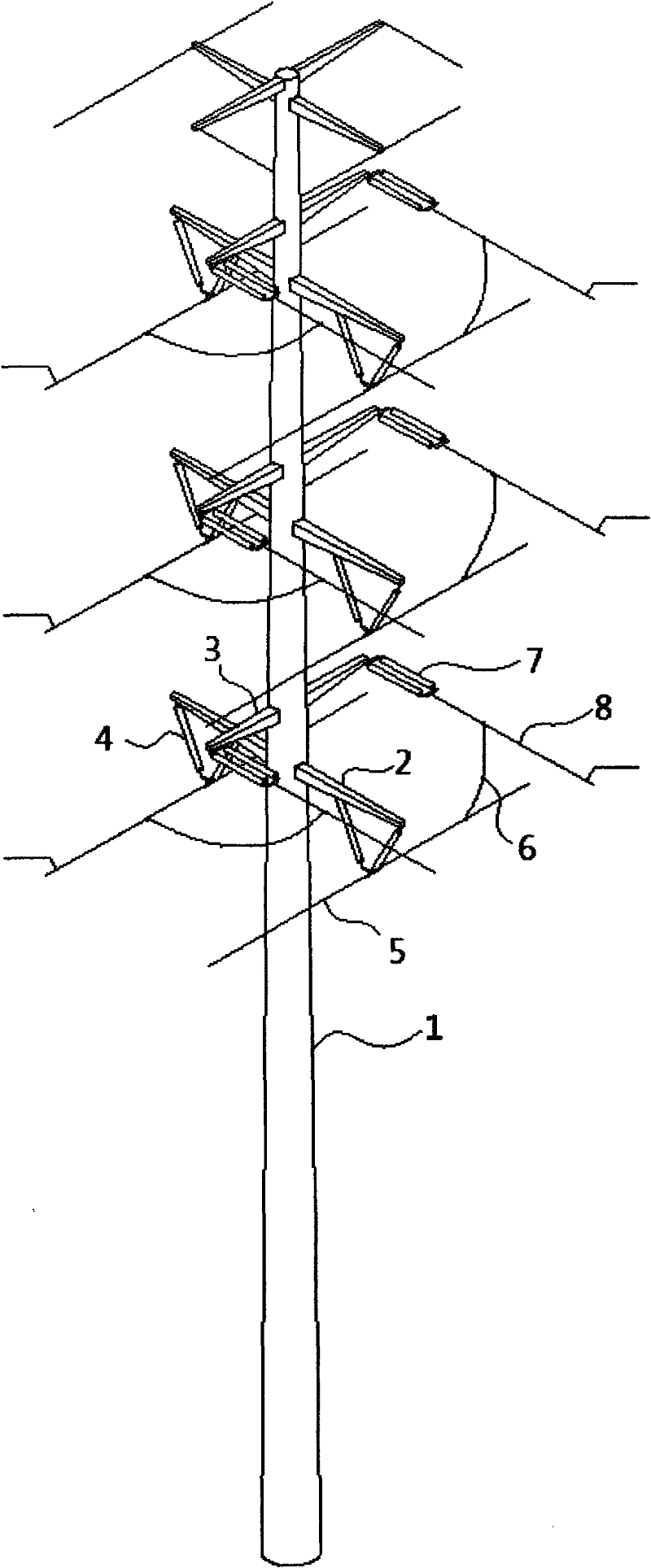

[0026] see figure 1 As shown, a steel pipe tower for a power transmission line includes a steel pipe tower trunk 1, a plurality of branch line cross arms 3 are arranged on the steel pipe tower trunk 1, and the tail ends of the branch line cross arms 3 are connected to branch lines 8 through tension clamps 7, The steel pipe tower trunk 1 is also provided with a main line cross arm 2, the main line cross arm 2 and the branch line cross arm 3 are arranged alternately, and the arm of the main line cross arm 2 is connected with a suspension line for suspending the main line 5 Clip 4.

[0027] Preferably, a pair of suspension wire clamps 4 are arranged on the arm of the main line cross arm 2, and the pair of suspension wire clamps 4 are arranged in a "V" shape.

[0028] Use the construction method of transmission line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com