Construction method of power transmission line steel tube tower

A construction method and transmission line technology, applied in the direction of towers, building types, buildings, etc., can solve problems such as failure to provide inspection and material selection, influence of reliability data, failure of smooth construction, etc., to achieve perfect and stable inspection work, construction personnel and The effect of reducing the amount of labor and reducing the use of tools and appliances on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A construction method for a transmission line steel pipe tower, characterized in that it comprises the following steps:

[0027] Step 1, material selection: select the appropriate steel pipe tower material according to the formula W=Wp+(WF1CF+0.5×WN1CN)+(WF2CF+0.5×WN2CN), where W is the optimal design target weight of the steel pipe member, and WP is the weight of a steel pipe , WF1, WF2 are the weight of the forged flange body at both ends, WN1, WN2 are the weight of all the bolts of the forged flange at both ends, CF, CN are the cost ratio coefficients of the forged flange body or the bolt and the steel pipe; the weight of the steel pipe member is The sum of the weight of the steel pipe, the weight of the forged flange body at both ends and the weight of one-third of the bolts.

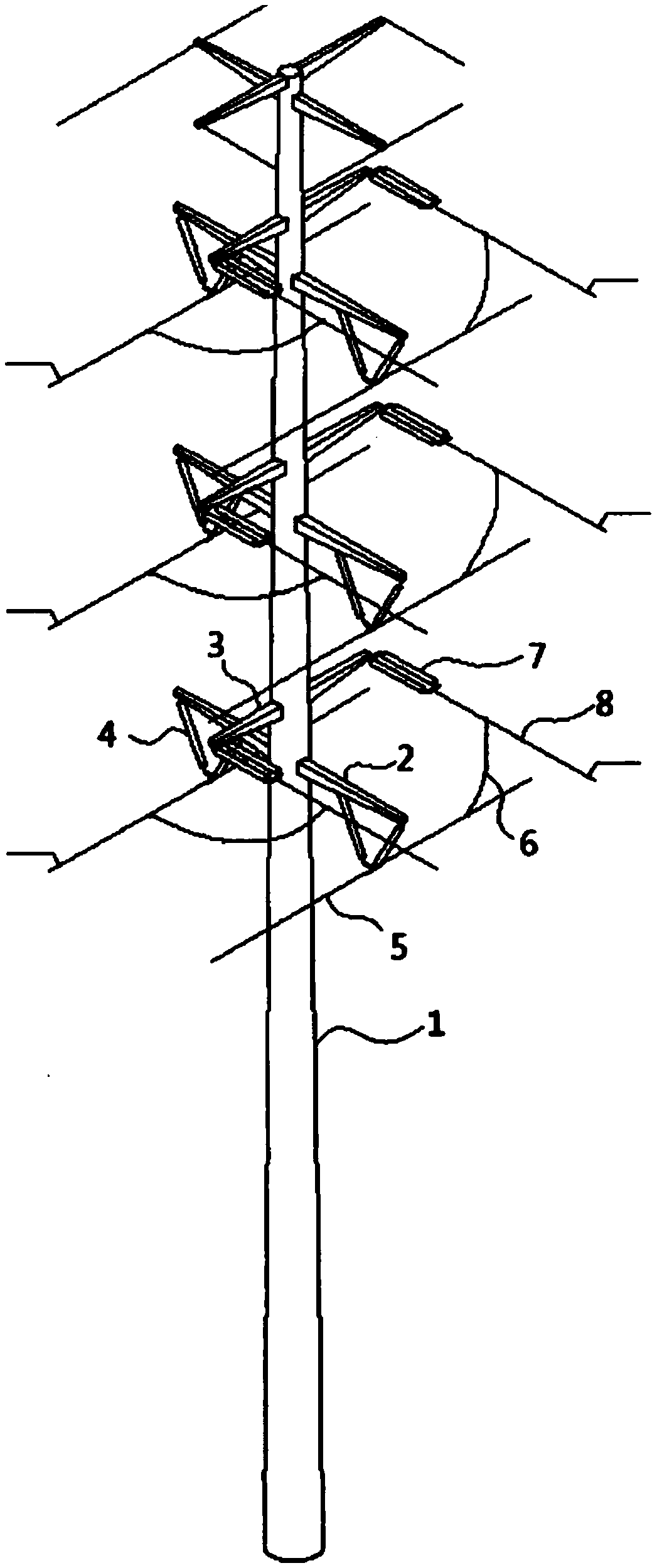

[0028] Step 2, manufacturing the steel pipe tower: welding the selected materials into the set steel pipe tower structure. like figure 1 As shown, the steel pipe tower of the transmission l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com