Feed-forward type microwave antenna

A microwave antenna and feed-forward technology, applied in antennas, electrical components, etc., can solve problems such as the difficulty of manufacturing large-scale CNC machine tools, the difficulty of making metal paraboloids, and energy loss, so as to improve the range of short-distance radiation, improve convergence performance, and avoid The effect of the reduction of electromagnetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

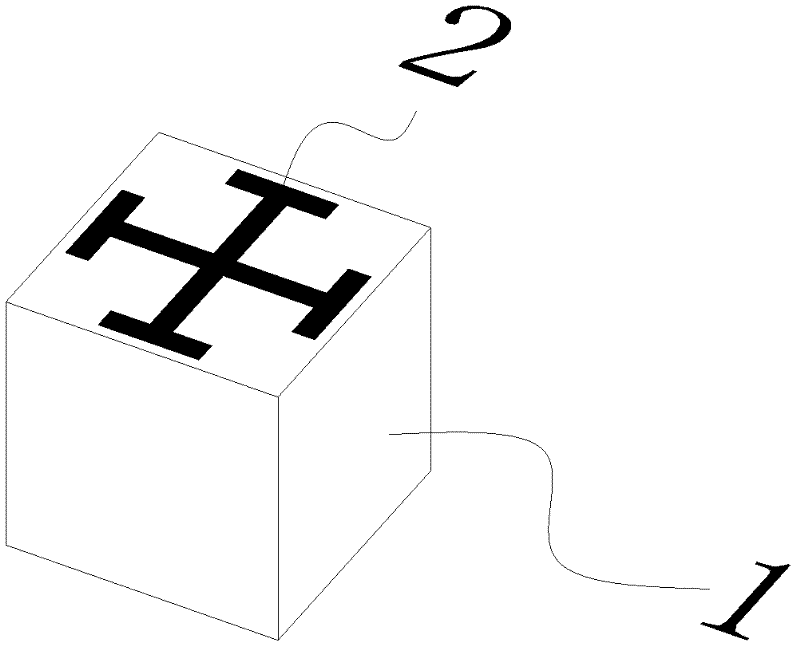

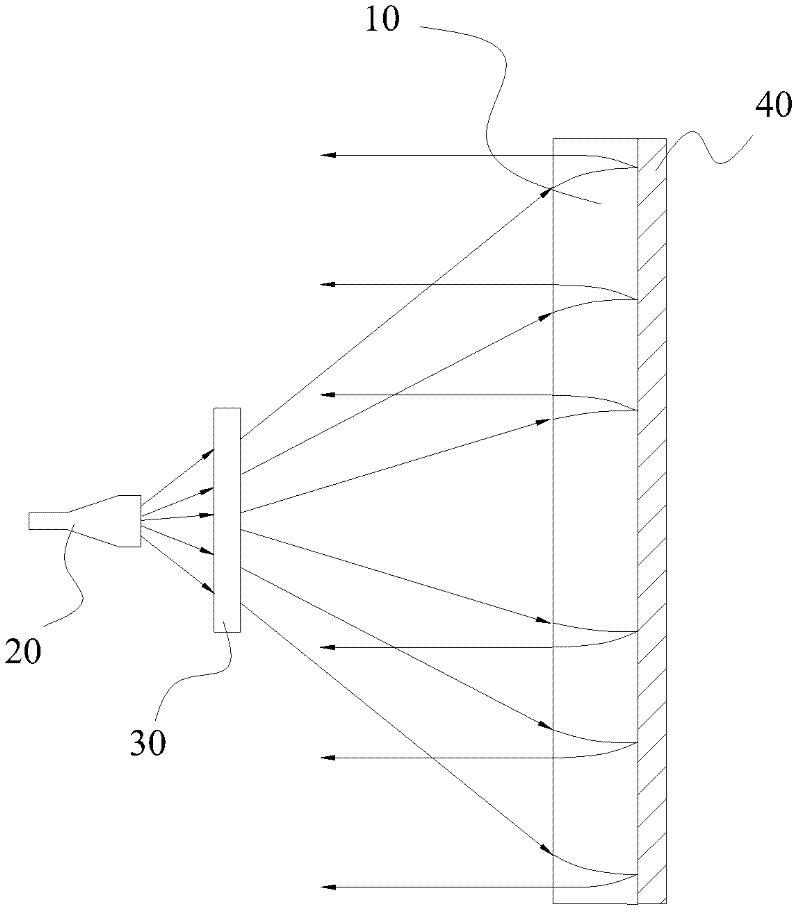

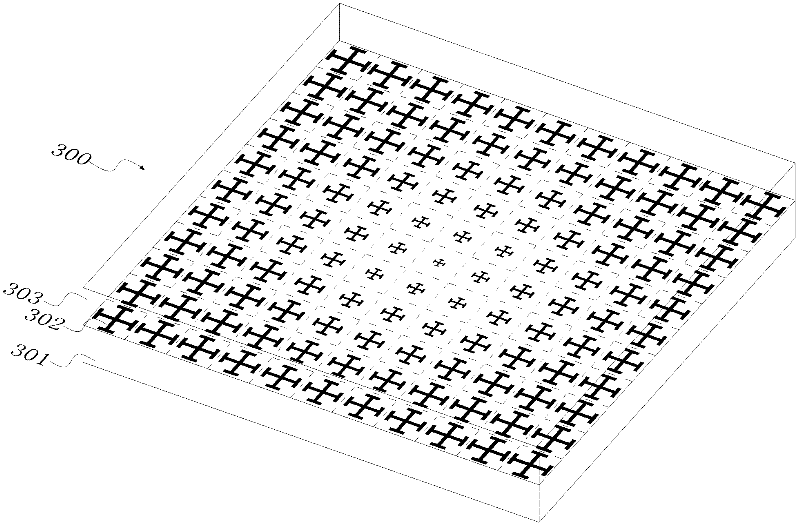

[0030]Light, as a kind of electromagnetic wave, when it passes through glass, because the wavelength of light is much larger than the size of atoms, we can use the overall parameters of the glass, such as the refractive index, rather than the detailed parameters of the atoms that make up the glass to describe The response of glass to light. Correspondingly, when studying the response of materials to other electromagnetic waves, the response of any structure in the material whose scale is much smaller than the wavelength of the electromagnetic wave to electromagnetic waves can also be described by the overall parameters of the material, such as the dielectric constant ε and magnetic permeability μ. By designing the structure of each point of the material, the dielectric constant and magnetic permeability of each point of the material are the same or different, so that the overall dielectric constant and magnetic permeability of the material are arranged in a certain order, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com