Slide rail device for vehicle

A technology for slide rails and vehicles, which is applied to special positions of vehicles, vehicle seats, vehicle components, etc., and can solve problems such as unsatisfactory configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

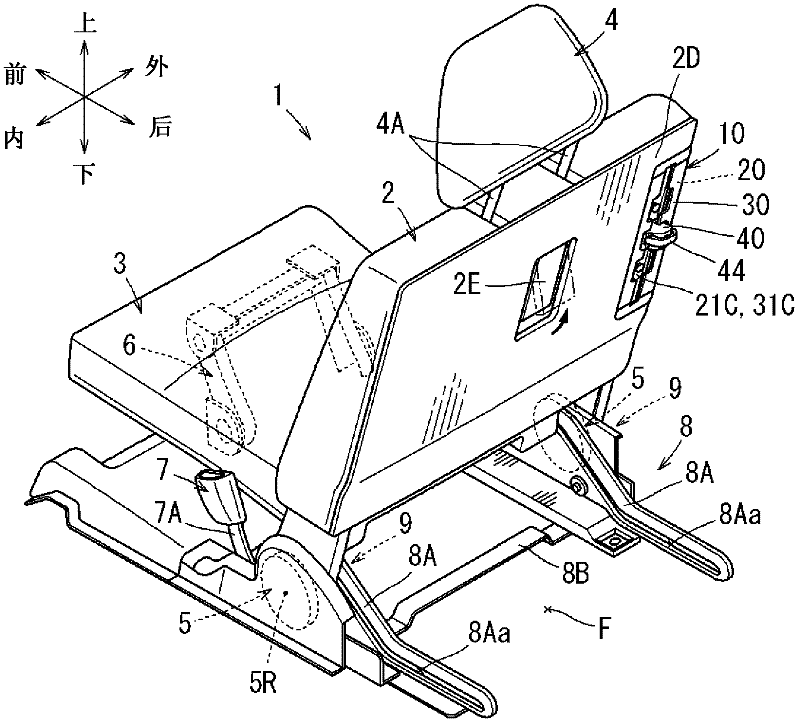

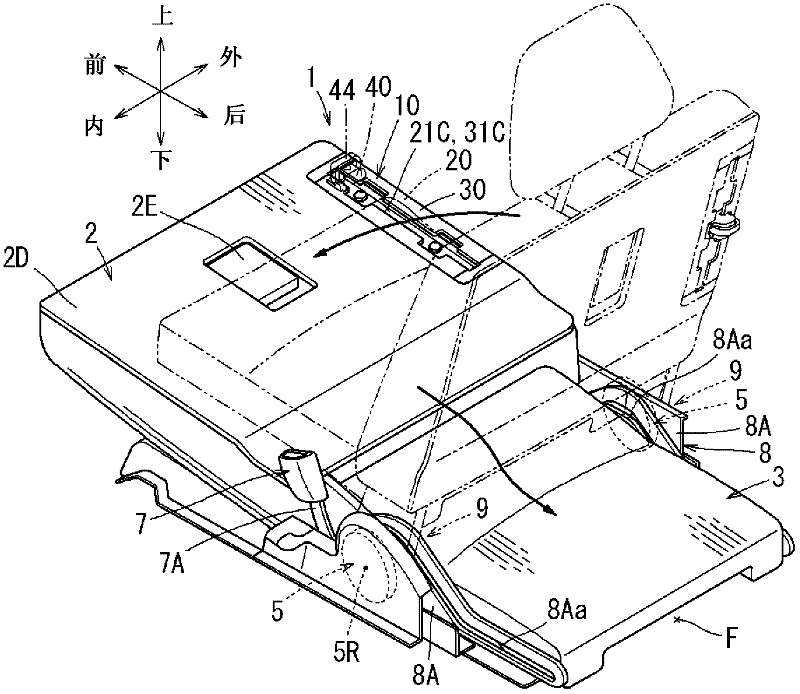

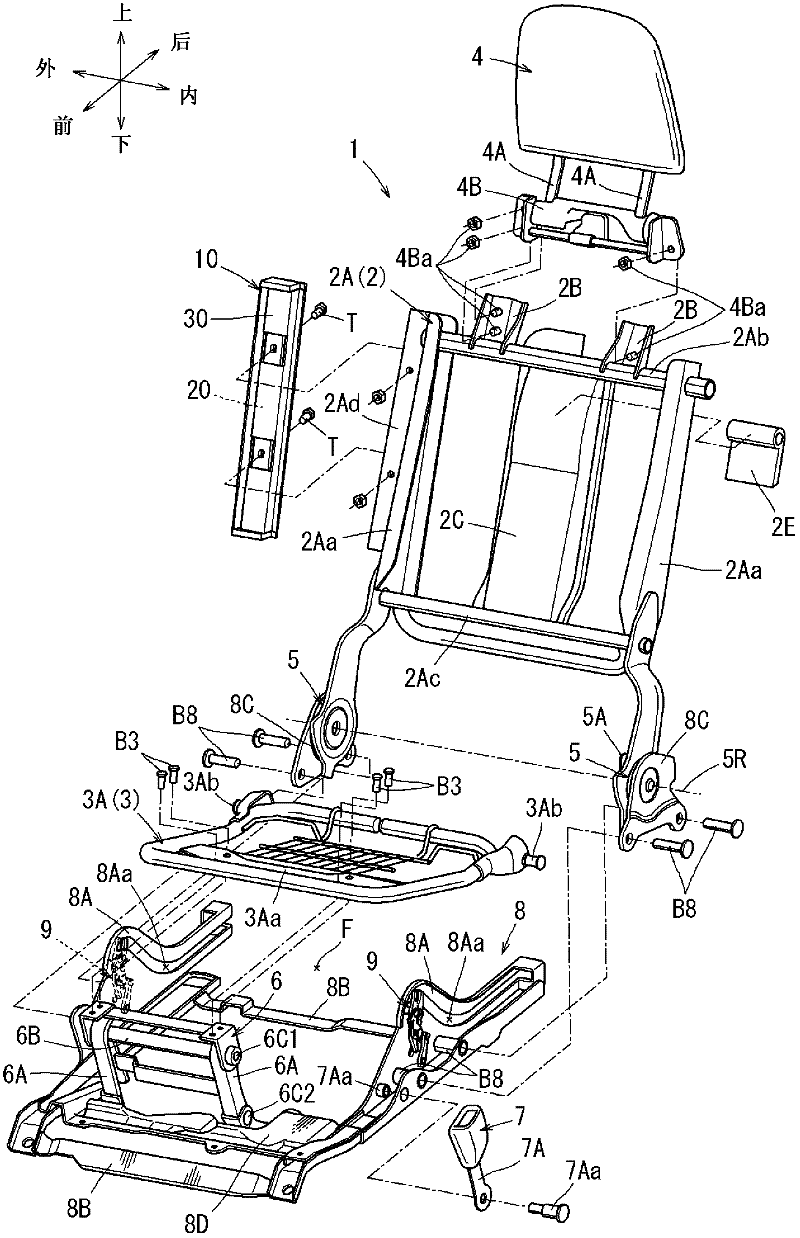

[0024] First, use Figure 1~Figure 8 The structure of the slide rail device 10 for a vehicle of Example 1 is demonstrated. here, figure 1 The structure of the vehicle seat 1 equipped with the vehicle slide rail device 10 of this embodiment is shown. The vehicle seat 1 is configured as a seat for seating on the rearmost side of a vehicle with three rows of seats (the third row of seats), and is configured to include a seat back 2 as a seat back of a seated occupant. A seat cushion 3 as a seating part and a headrest 4 for supporting the head.

[0025] Specifically, the vehicle seat 1 is a seat arranged on the right side when viewed from the rear side of the vehicle among the two left and right seats constituting the third row of seats, and is adjacent to the outer side portion facing the right side as shown in the figure. The side wall liner constituting the side wall portion of the vehicle body not shown is arranged, and the other seat (not shown) constituting the third row of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com