Universal buffering guide sleeve

A guide sleeve and universal technology, applied in the field of buffer limit devices, can solve the problems of reduced deformation range, aging, molten steel splashing and harming the human body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

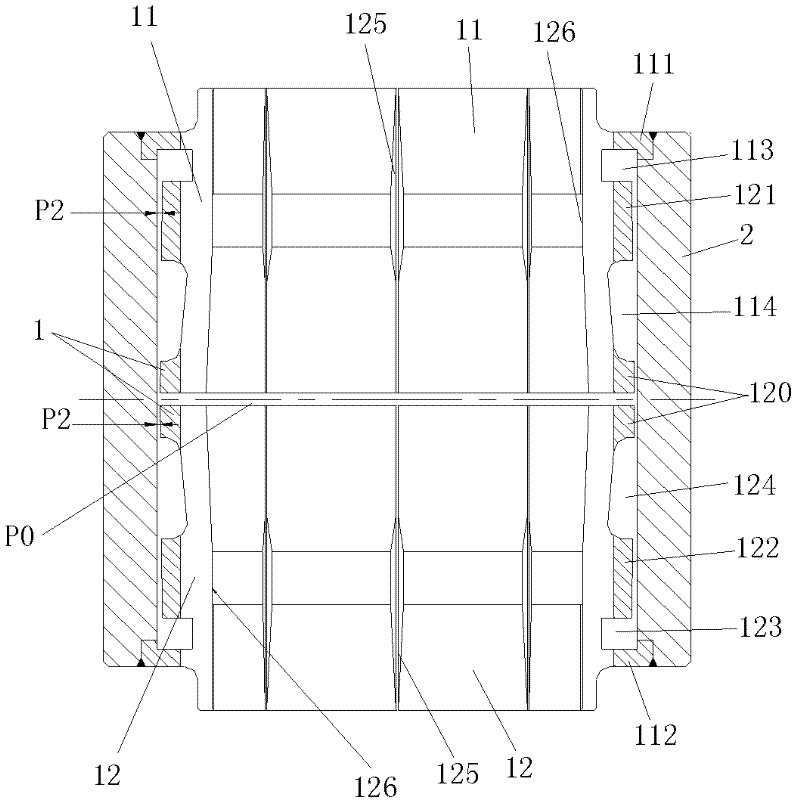

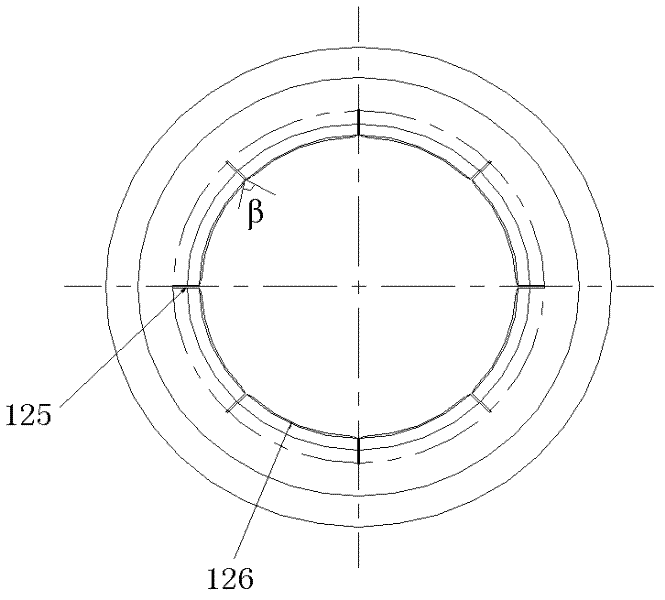

[0022] see figure 2 and 3 , the present invention is provided with annular bushing 1 (circular bushing) and annular casing 2 (annular annular casing). Both the annular bushing 1 and the annular casing 2 are metal annular casings. The annular bush 1 is a split structure, which is composed of the upper annular bush 11 and the lower annular bush 12, which facilitates the installation of the annular bush 1 into the annular shell 2 (when the buffer volume is small, there is no large axial Extended needs can also be integrated structure). The gap P0 between the upper ring bushing 11 and the lower ring bushing 12 is the boundary, and the upper ring bushing 11 and the lower ring bushing 12 are symmetrically arranged up and down. The radial flange 111 at the upper end of the upper annular bushing 11 is fixedly connected (welded or threaded) to the upper end of the annular casing 2, and the radial flange 112 at the lower end of the lower annular bush 12 is fixedly connected (welded ...

Embodiment 2

[0025] Similar to Embodiment 1, the difference is that this embodiment is a universal buffer guide sleeve with a three-stage buffer structure. see Figure 4 and 5 , The upper annular bushing 11 and the lower annular bushing 12 are arranged symmetrically up and down in the axial direction. There are first-level buffer gap a, second-level buffer gap b, and third-level buffer gap c, where a Figure 4 and 5 The rest of the labels in are correspondingly consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com