Combined light steel keel concrete mixed structure and construction method thereof

A light steel keel and mixed structure technology, applied to building components, building structures, walls, etc., can solve the problems of manpower consumption, complicated reinforcement process, and lack of material resources, so as to improve construction speed, facilitate construction, and meet standards high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

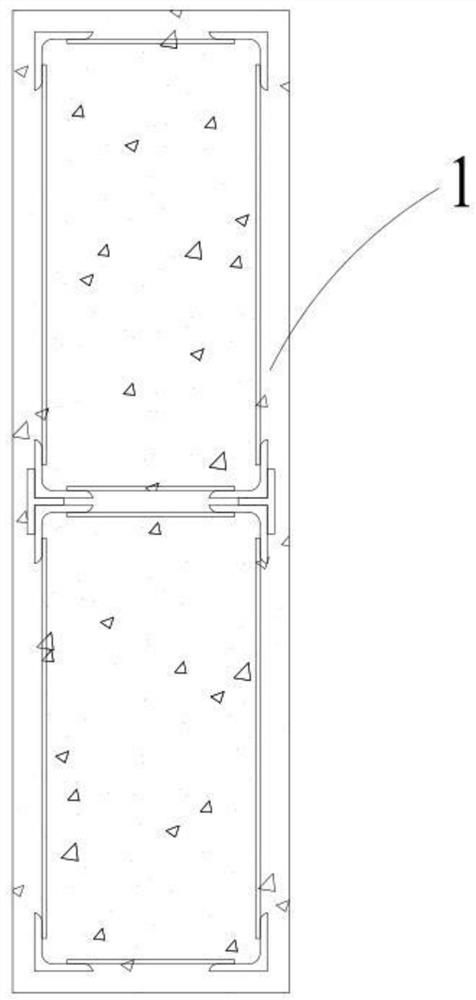

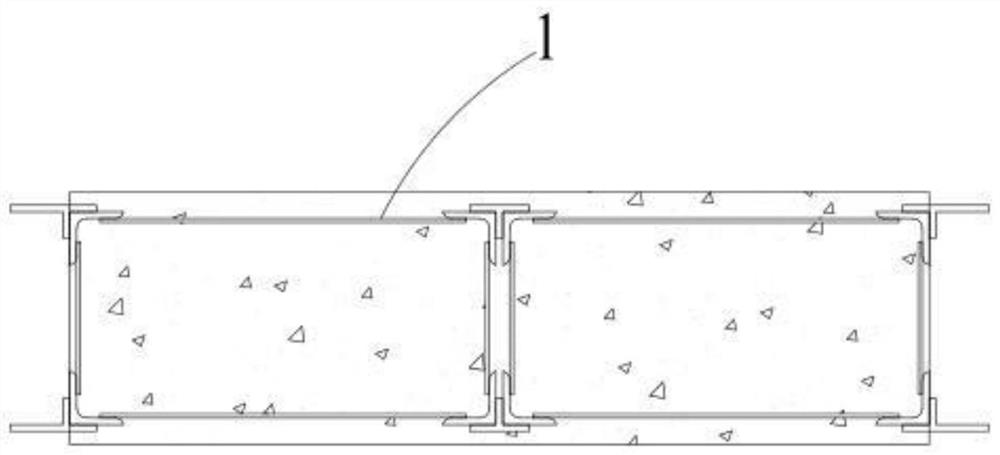

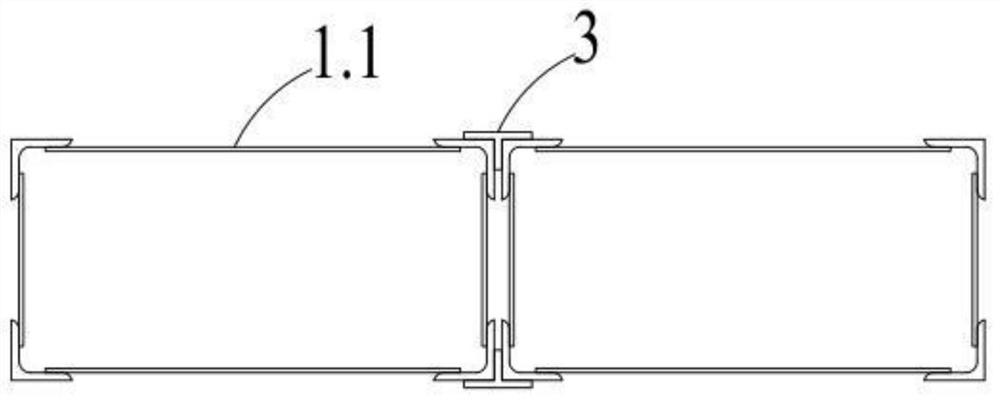

[0059] Combined light steel keel concrete hybrid structure, there are two light steel keel units A1, and the two light steel keel units A1 are arranged in the word "one" or "I"; the connection of the two light steel keel units A1 is through The two limb bars 1.1.1 on the same side in the limb truss unit A1.1 are welded and fixed to the two limb bars 1.1.1 on the same side in the other limb truss unit A1.1 through the connector 3; figure 1 As shown, when two light steel keel units A1 are arranged in the shape of "I", they can be used as beams; as figure 2 , image 3 As shown, when two light steel keel units A1 are arranged in a "one" shape, they can be used as shear walls.

Embodiment 2

[0061] Combined light steel keel concrete hybrid structure, the light steel keel unit A1 is two, the light steel keel unit B2 is one, and the two light steel keel units A1 are respectively located on the adjacent sides of the light steel keel unit B2; as Figure 4 , Figure 5 As shown, among them, the connection of light steel keel unit A1 and light steel keel unit B2 is through the connection of two light steel keel units A1, two limb bars 1.1.1 and the limb truss unit on the same side in A1.1 The two limb bars 1.1.1 on the same side in B2.1 are fixed by welding the connector 3, and the two limb truss units A1.1 are respectively located on the adjacent sides of the limb truss unit B2.1, which can be used as L-shaped Hybrid shear walls.

Embodiment 3

[0063] Combined light steel keel concrete hybrid structure, the light steel keel unit A1 is three, the light steel keel unit B2 is one, and the three light steel keel units A1 are respectively located on the adjacent three sides of the light steel keel unit B2; Figure 6 , Figure 7 As shown, among them, the light steel keel unit A1 and the light steel keel unit B2 are connected through the two limb bars 1.1.1 on the same side in the limb truss unit A1.1 and the two limb bars on the same side in the limb truss unit B2.1 The limb bar 1.1.1 is welded and fixed by the connecting piece 3, and the two limb truss units A1.1 are respectively located on three adjacent sides of the limb truss unit B2.1, which can be used as a T-shaped hybrid shear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com