Elastic multi-model grinding end surface positioning device

A technology of positioning device and end face, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc. suitable for grinding workpiece planes, can solve the problem that the axial length and dimension of gears cannot be consistent, and achieve the improvement of processing assurance ability and production The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

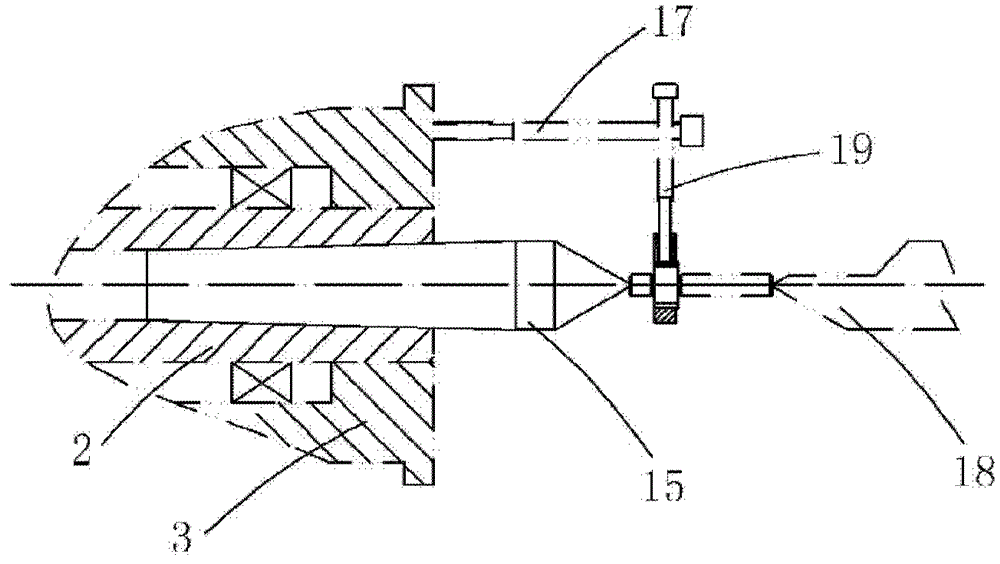

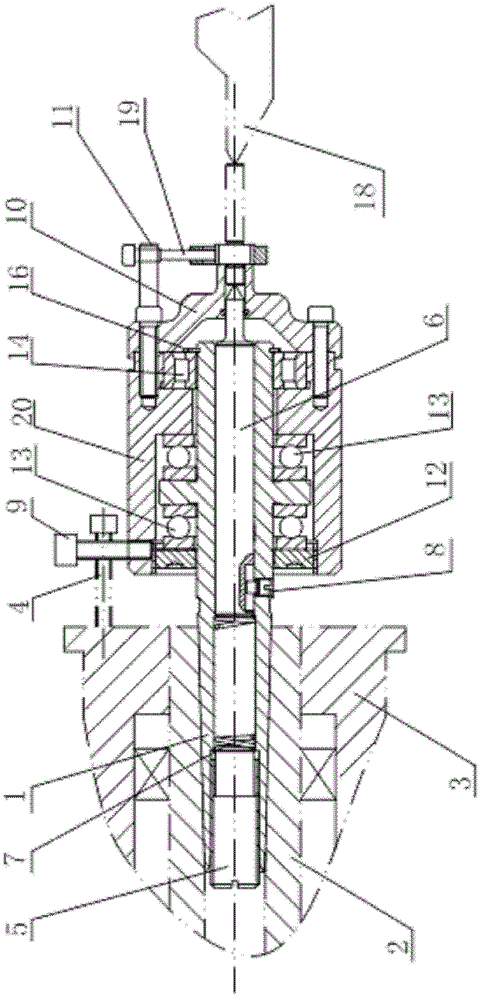

[0025] Example: see image 3 , the elastic grinding end surface positioning device of this embodiment is suitable for improving the processing guarantee ability of the axial length of the product shaft, and the device has:

[0026] A cylindrical main shaft seat 1, its rear end is fixedly connected in the inner hole of the grinding machine main shaft 2, and the front end extends out of the grinding machine main shaft; the grinding machine main shaft 2 is coaxially connected with the grinding machine flange 3, which is fixed on the grinding machine main shaft 2. Connected with the first driving lever 4 parallel to the axis of the main shaft seat 1, the first driving lever is used to toggle the connecting seat 20 to rotate.

[0027] An adjusting screw plug 5 is threadedly connected to the inner cavity of the rear end of the main shaft seat 1, and a sliding top 6 is coaxially connected to the inner cavity of the front end. A compression spring 7 is provided in the inner hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com