Embossing press for lubrication belt

A technology of embossing machine and frame, which is applied in decorative arts, embossed ornaments and other directions, can solve the problems of inconvenient adjustment, difficult adjustment, consumption and the like, and achieve the effect of convenient embossing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

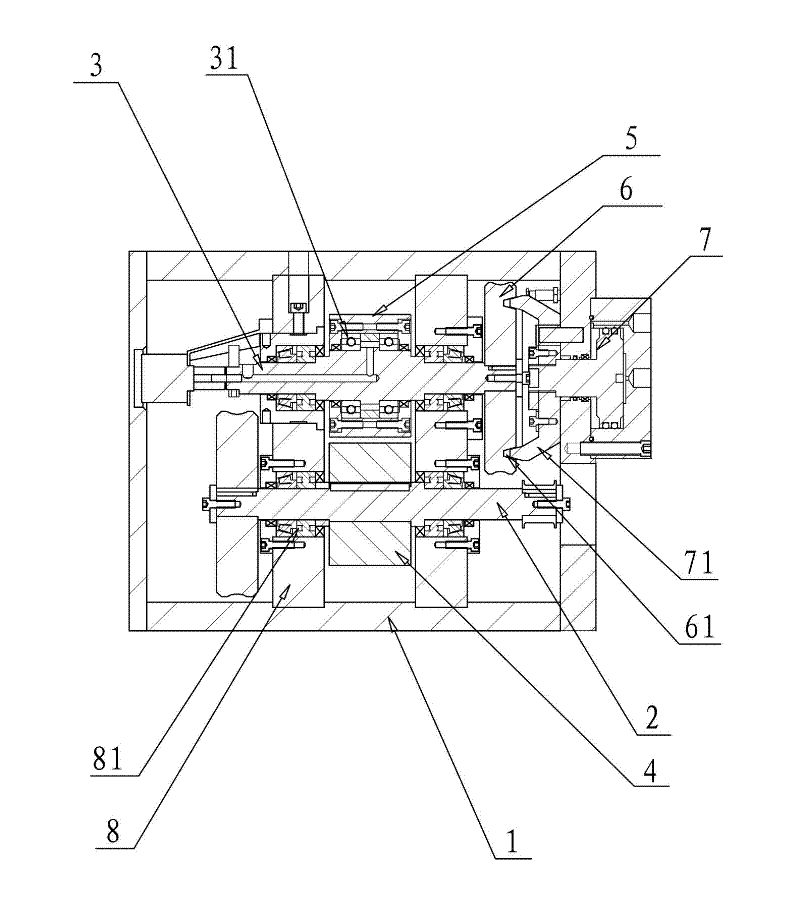

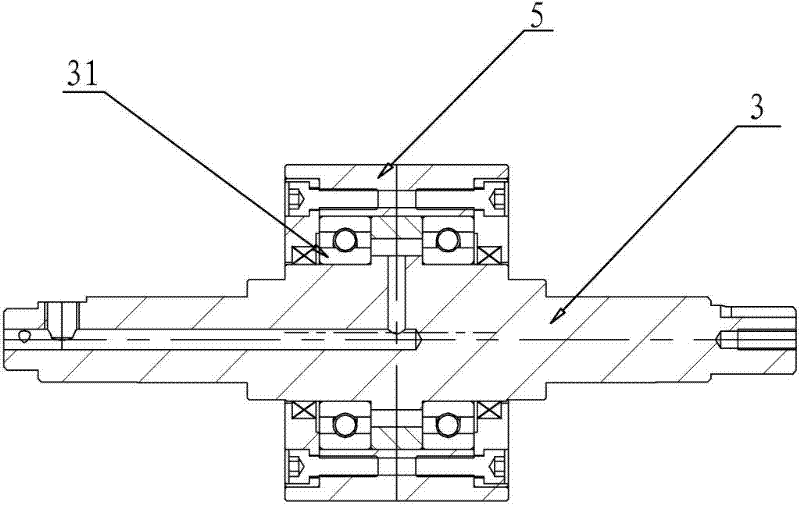

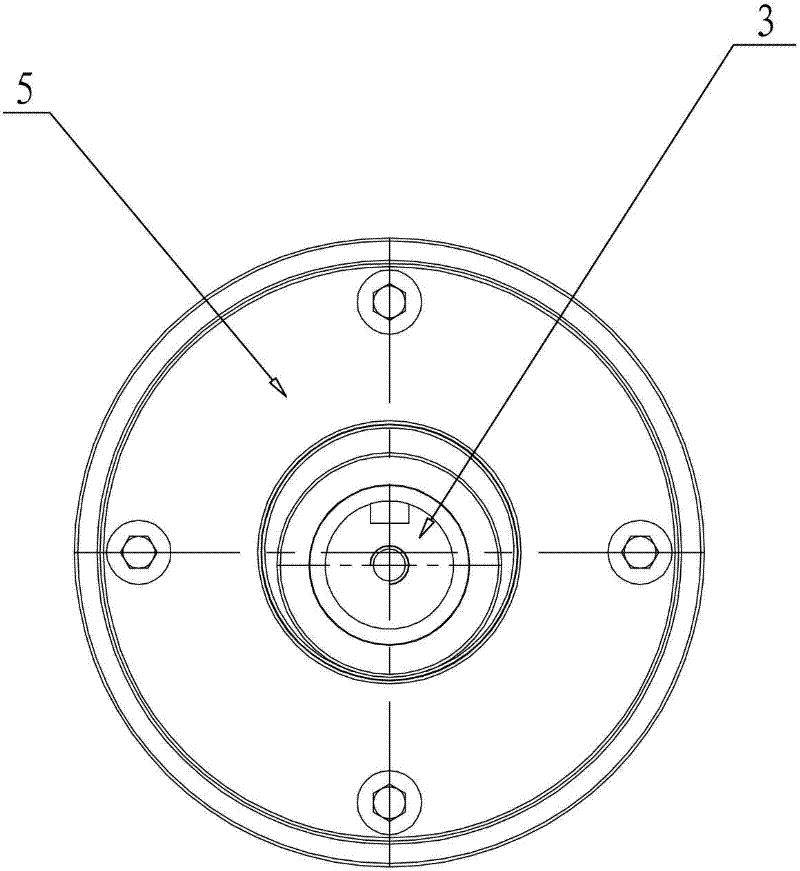

[0016] refer to Figure 1 ~ Figure 4 , the present invention is an embossing machine for lubricating belts, comprising a frame 1 and a driving shaft 2 and a driven shaft 3 installed in the frame 1 and arranged parallel to each other, the driving shaft 2 is fixedly mounted with a driving wheel 4, The driven shaft 3 is provided with a driven wheel 5 that can rotate around the shaft. The center of the shaft of the driven shaft 3 and the axis of the driven wheel 5 are not on a straight line. 3 fixtures.

[0017] In this invention, the driven wheel 5 rotating around the driven shaft 3 is eccentrically arranged, so that the axis center of the driven wheel 5 and the center of the driven shaft 3 are not on the same straight line, so that the surface of the brake strip with different thickness specifications is embossed , the distance between the closest point between the surface of the driving wheel 4 and the driven wheel 5 can be eccentrically adjusted by rotating the driven shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com