Plants for toilet paper processing

A technology of toilet paper and paper feeding roller, which is applied in the direction of machining/deformation, household appliances, etc., can solve the problems of surface wrinkles of toilet paper, uneven surface and end surface of toilet paper, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

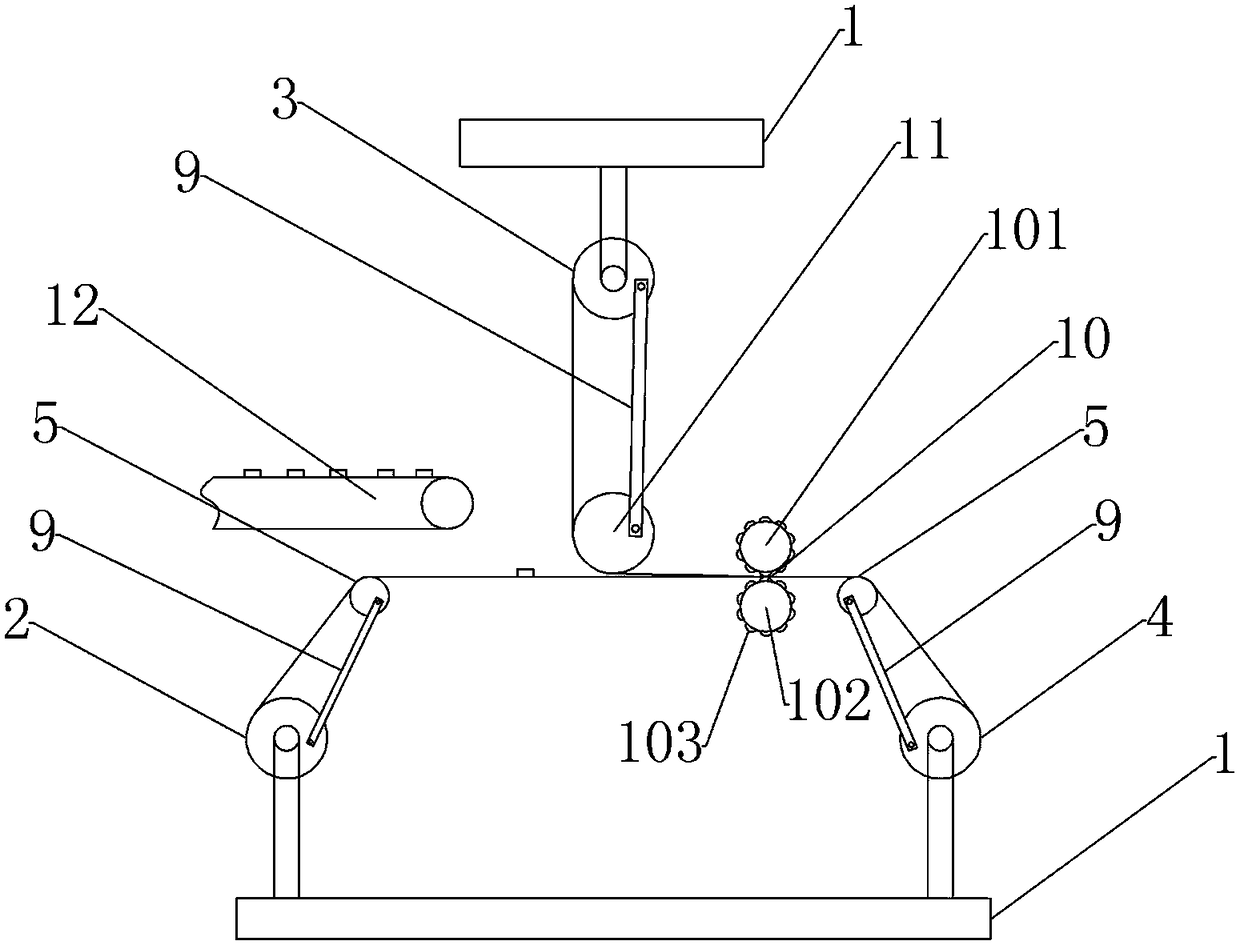

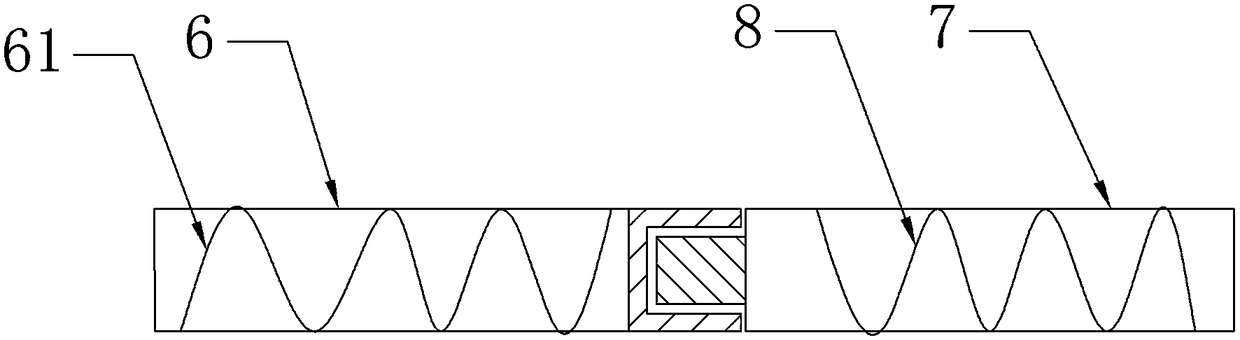

[0024] The reference numerals in the drawings of the description include: frame 1, first paper feed roller 2, second paper feed roller 3, winding roller 4, leveling rod 5, first rod body 6, first spiral groove 61, The second rod body 7, the second spiral groove 8, the connecting rod 9, the embossing device 10, the upper rotating shaft 101, the lower rotating shaft 102, the protrusion 103, the positioning rotating shaft 11, and the conveyor belt 12.

[0025] This example figure 1 and figure 2As shown, the first paper feeding roller 2 and the winding roller 4 are fixedly connected to the bottom of the frame 1, and the axis centers of their rotating shafts are on the same horizontal line. Two leveling rods 5 are arranged above the first paper feeding roller 2 and the winding roller 4, the leveling rods 5 are fixedly connected with the frame 1, and the tops of the two leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com