Method for sewing and braiding hank yarns to be dyed

A knitting and sewing technology, which is applied in sewing equipment, textiles and papermaking, etc., can solve the problems of high difficulty in knitting and knitting with finger-inserted hooks, inability to realize free sewing of sewing objects, low efficiency, etc., and achieve mechanization or automation Operation, improvement of labor efficiency and production efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

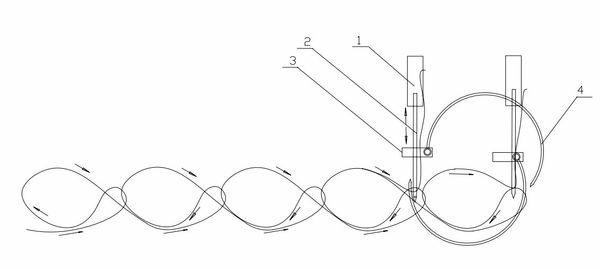

[0026] A sewing and knitting method for dyed skein, comprising the following process steps:

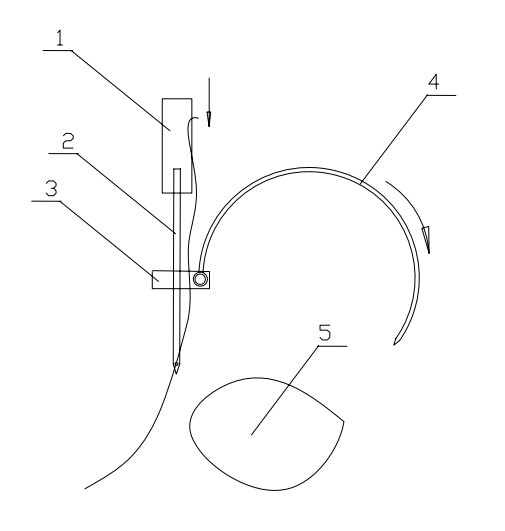

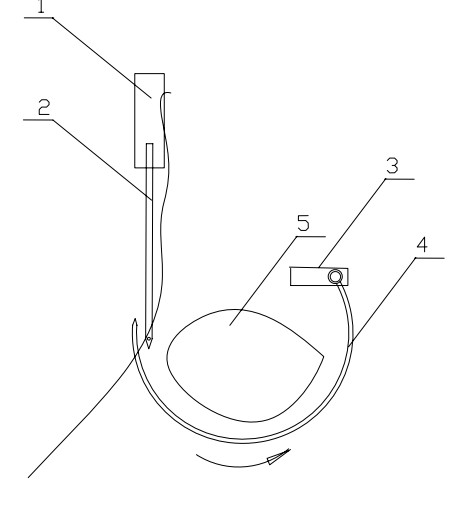

[0027] A. According to figure 2 : The head of the sewing twisting machine is provided with a lead needle bar 1, and the lower end of the thread needle bar 1 is vertically provided with a lead needle 2 with a hole in the downward direction, and at the same time, a suspension hook is also arranged at the head of the sewing twisting machine Thread needle bar 3 is provided with arc-shaped suspended thread needle 4 on it; described lead thread needle bar 1 moves vertically up and down and horizontally left and right, and suspended thread needle bar 3 moves horizontally left and right, and at the same time The suspended crochet needle 4 rotates above and below the filament bundle 5; in the initial state, the lead needle bar 1 is directly above the suspended crochet needle bar 3, and the suspended crochet needle 4 is positioned above the suspended crochet needle bar 3. The right side of th...

Embodiment 2

[0037] A sewing and knitting method for dyed skein, comprising the following process steps:

[0038] A. According to figure 2 : The head of the sewing twisting machine is provided with a lead needle bar 1, and the lower end of the thread needle bar 1 is vertically provided with a lead needle 2 with a hole in the downward direction, and at the same time, a suspension hook is also arranged at the head of the sewing twisting machine Thread needle bar 3 is provided with arc-shaped suspended thread needle 4 on it; described lead thread needle bar 1 moves vertically up and down and horizontally left and right, and suspended thread needle bar 3 moves horizontally left and right, and at the same time The suspended crochet needle 4 rotates above and below the filament bundle 5; in the initial state, the lead needle bar 1 is directly above the suspended crochet needle bar 3, and the suspended crochet needle 4 is positioned above the suspended crochet needle bar 3. The right side of th...

Embodiment 3

[0048] A sewing and knitting method for dyed skein, comprising the following process steps:

[0049] A. According to figure 2 : The head of the sewing twisting machine is provided with a lead needle bar 1, and the lower end of the thread needle bar 1 is vertically provided with a lead needle 2 with a hole in the downward direction, and at the same time, a suspension hook is also arranged at the head of the sewing twisting machine Thread needle bar 3 is provided with arc-shaped suspended thread needle 4 on it; described lead thread needle bar 1 moves vertically up and down and horizontally left and right, and suspended thread needle bar 3 moves horizontally left and right, and at the same time The suspended crochet needle 4 rotates above and below the filament bundle 5; in the initial state, the lead needle bar 1 is directly above the suspended crochet needle bar 3, and the suspended crochet needle 4 is positioned above the suspended crochet needle bar 3. The right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com