Production method of light insulating heatproof firebrick

A technology of insulating heat-resistance and production method, which is applied in the production field of lightweight insulating and heat-resisting fire bricks, can solve problems such as unstable market supply, and achieve the effects of broadening access, saving combustion costs, and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

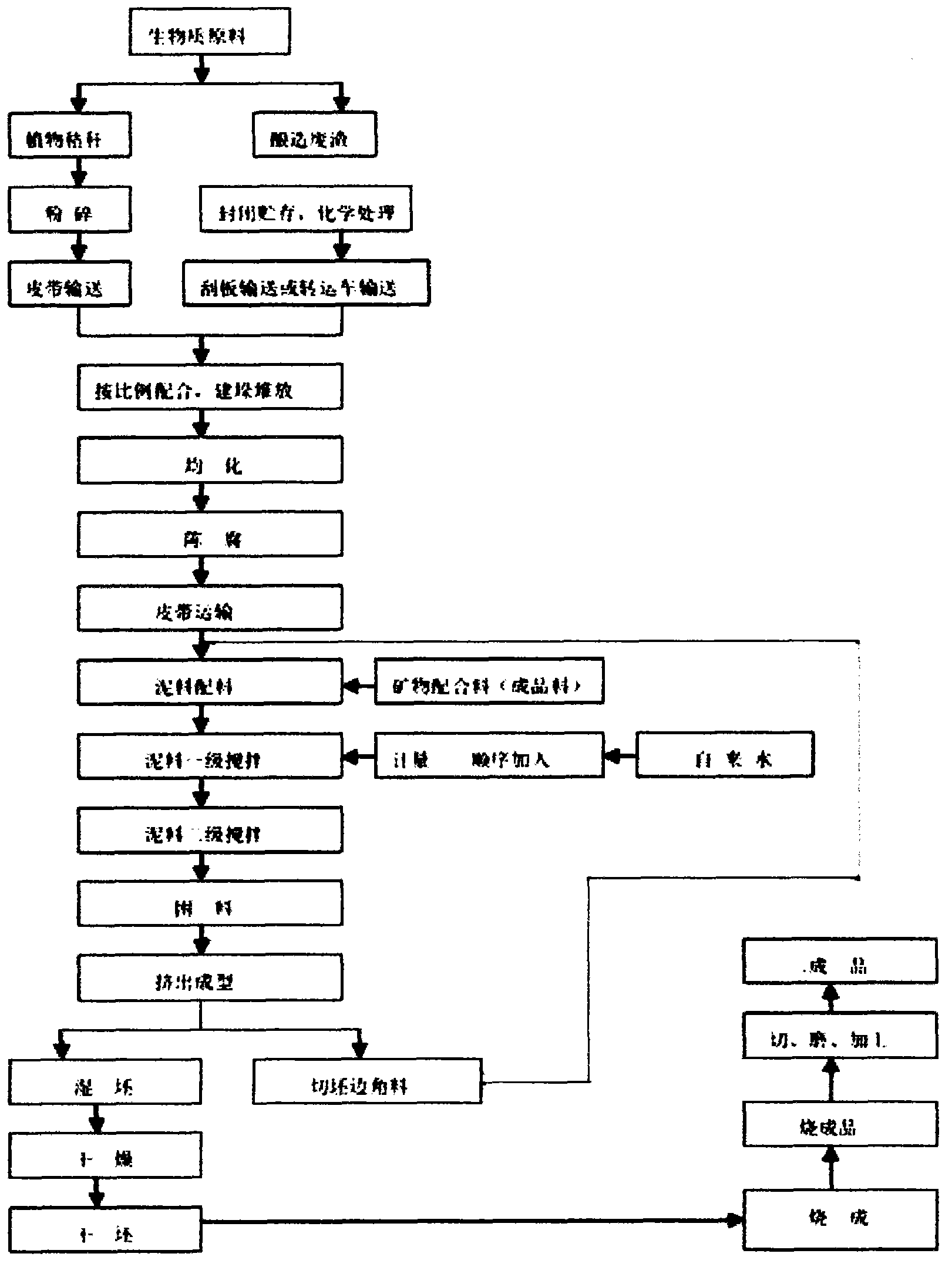

[0023] Such as figure 1 Shown, the production method of light insulation heat-resistant refractory brick of the present invention, comprises the steps:

[0024] (1) Using biomass materials to brew waste residues including wine residues, vinegar residues, sugar residues, sauce residues and plant straws including barley straw, sorghum straw, rice straw, and oat straw;

[0025] (2) According to different processing methods, make it obtain particle size, humidity, resilience and other properties in line with the requirements of the pore-forming material index;

[0026] (3) Coordinate the above-mentioned materials with the semi-raw minerals of the coal mine according to a certain ratio, send them into the mixer and add water to mix them into mud;

[0027] (4) Place the mud material for a certain period of time to trap the material, so that the moisture in the batch material is fully uniform;

[0028] (5) extrude the wet billet that contains certain moisture with the different len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com