Working device with eight forward rotating type connecting rods for loading end of backhoe loader

A technology of backhoe loader and working device, which is applied in loading/unloading, mechanically driven excavator/dredger, transmission device, etc., can solve the problem of small breakout force, achieve reasonable bridge load distribution of the whole machine, and improve operation. The effect of efficiency and job balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

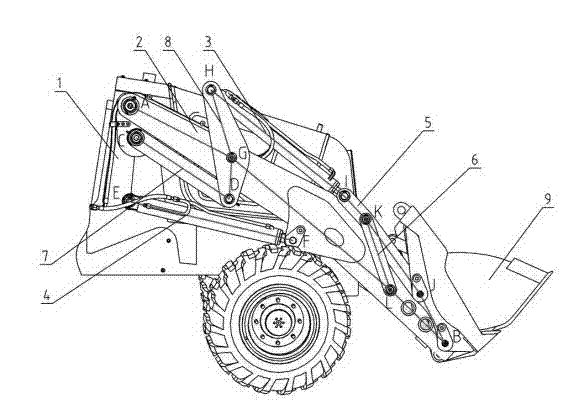

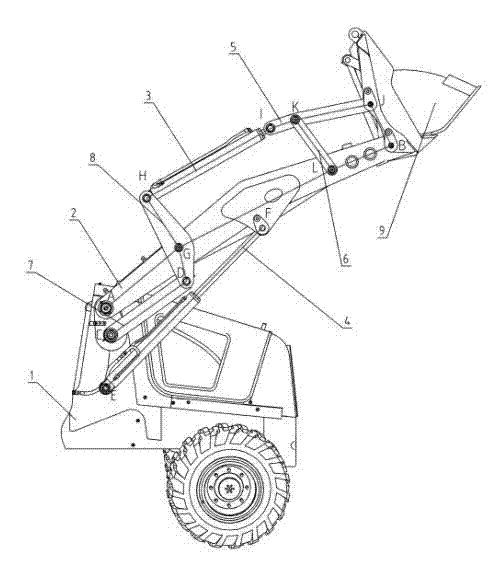

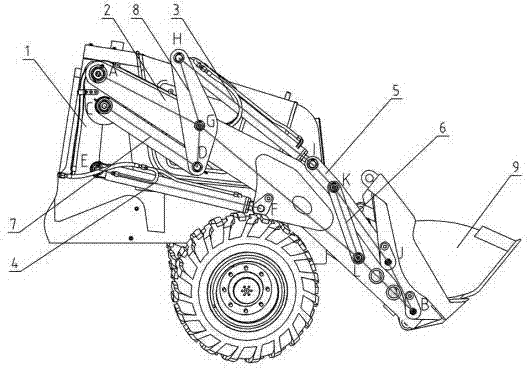

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. As shown in the figure, an eight-link forward working device at the loading end of a backhoe loader includes a front frame 1, a boom 2, a bucket cylinder 3, and a boom cylinder. 4. Bucket rocker arm 5, bucket pull rod 6, boom pull rod 7, boom rocker 8 and bucket 9; it is characterized in that: the vehicle frame 1 is respectively hinged with one end of the boom 2 at point A, and One end of the arm pull rod 7 is hinged at point C, and one end of the boom cylinder 4 is hinged at point E. The other end of the boom 2 and the bucket 9 are hinged at point B. One end is hinged at point D, and the other end of the boom cylinder 4 is hinged at point F in the middle of the boom 2; the middle part of the boom rocker 8 is hinged at point G with the boom 2, and point G is located at points A and F between; the other end of the boom rocker 8 is hinged at point H with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com