Small self-propelled disc type mowing-flattening harvesting machine

A disc-type harvester technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of inability to adapt to the production of alfalfa by small farmers, and achieve improved controllability and safety, simple and compact structure, imitation good shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the drawings and embodiments.

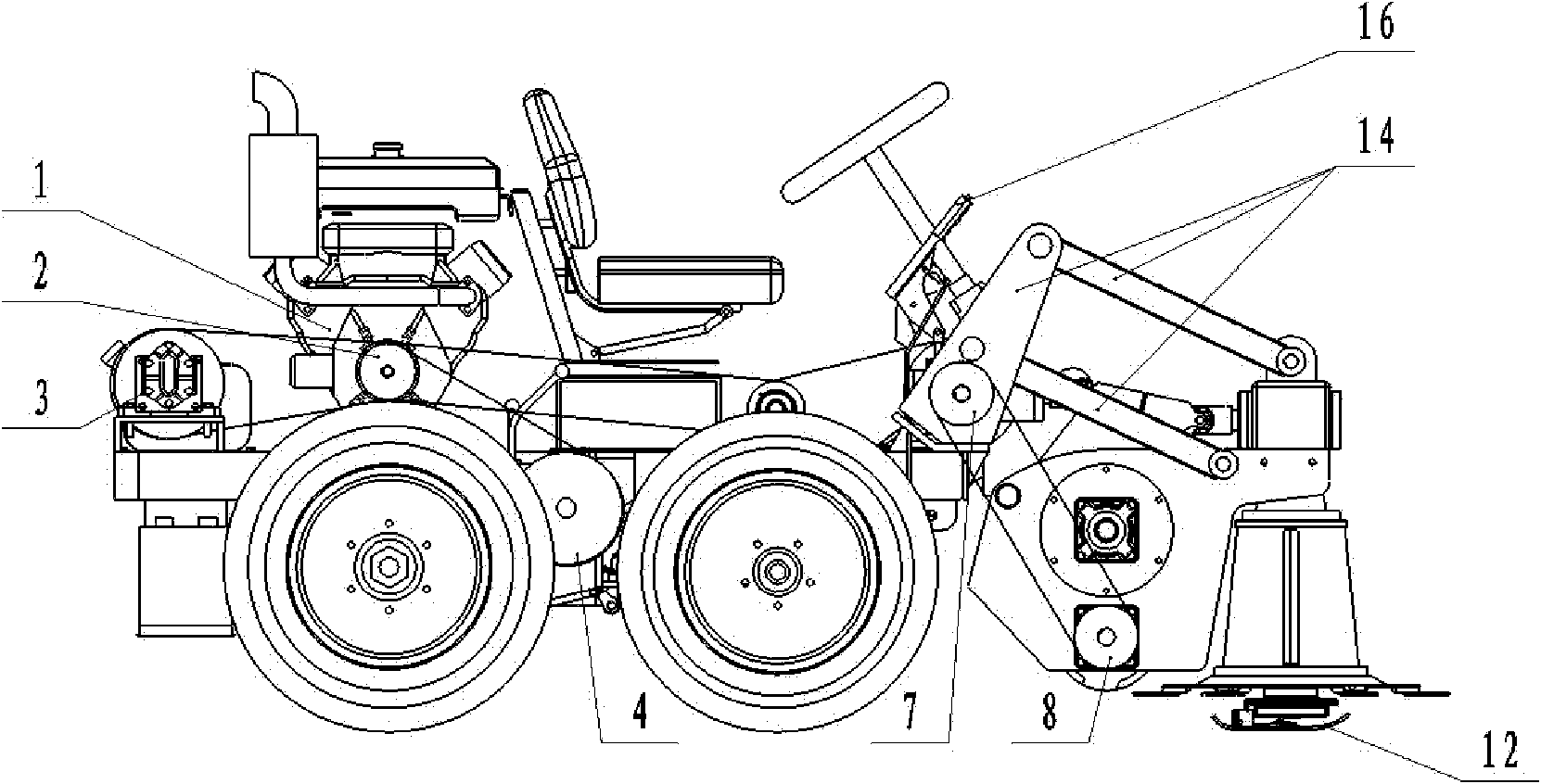

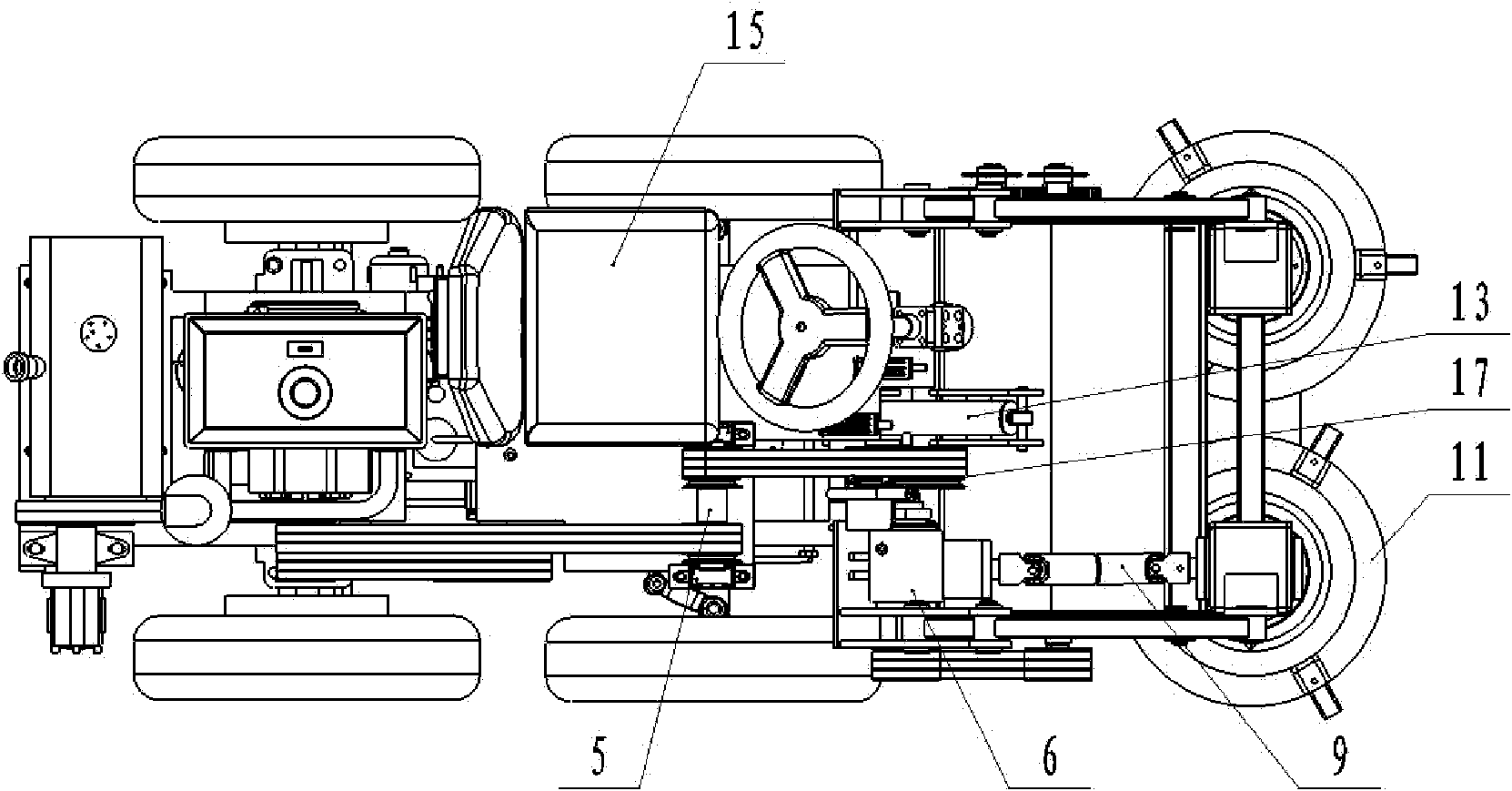

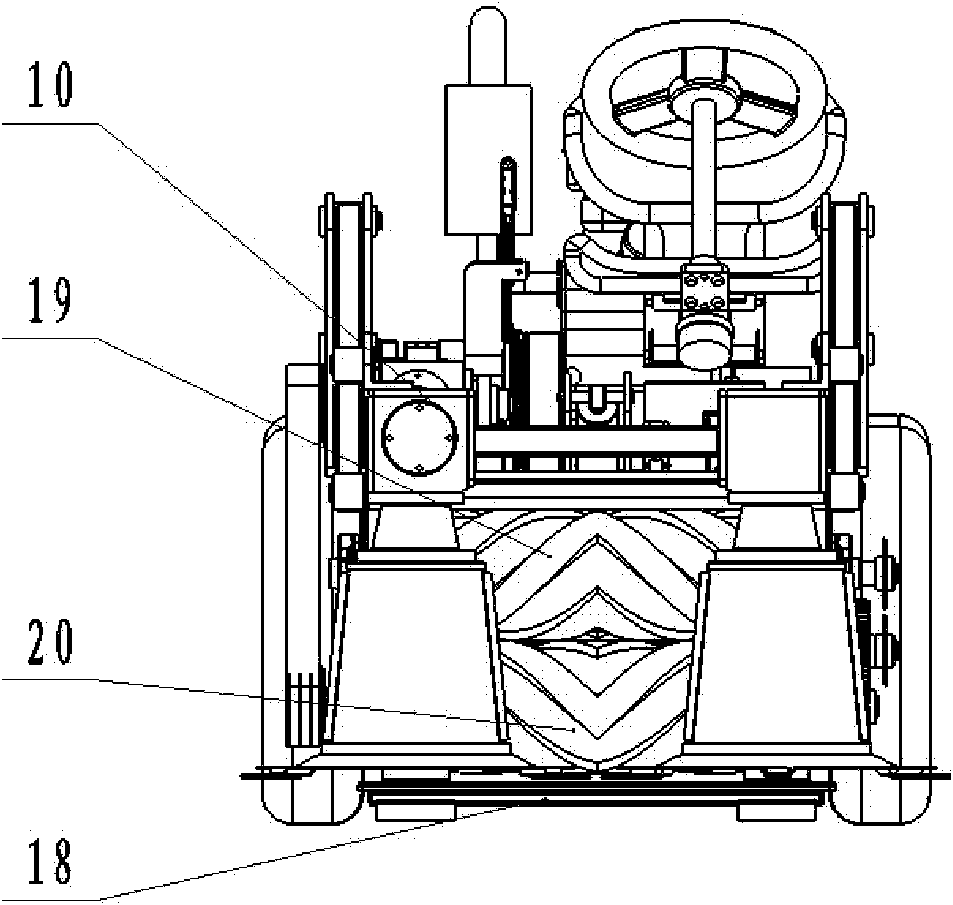

[0032] Such as Figure 1-2 As shown, the small self-propelled disc-type cutting and flattening harvester of the present invention includes a walking part and a disc-type cutting and flattening mechanism. Moreover, its structure is arranged such that the power transmission system is arranged on the right side of the vehicle body, the cab 15 is arranged on the left side of the vehicle body, and the disc-type cutting and flattening mechanism is installed at the front end of the walking part.

[0033] Among them, the walking part includes the engine 1 behind the cab 15; the power transmission system includes the rear axle gearbox pulley 4, which is connected to the engine 1 through the engine pulley and transmits the engine power to the walking part; the gear box 6, which passes The pulley set 5 is connected to the engine 1 and transmits the engine power to the disc-type cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com