Parallel robot and wrist mold

A robot and parallel technology, applied in the direction of manipulators, program-controlled manipulators, joints, etc., can solve the problems of large total weight, heavy weight, speed, rigidity and precision limitations of serial robots, and achieve improved actuation balance and controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

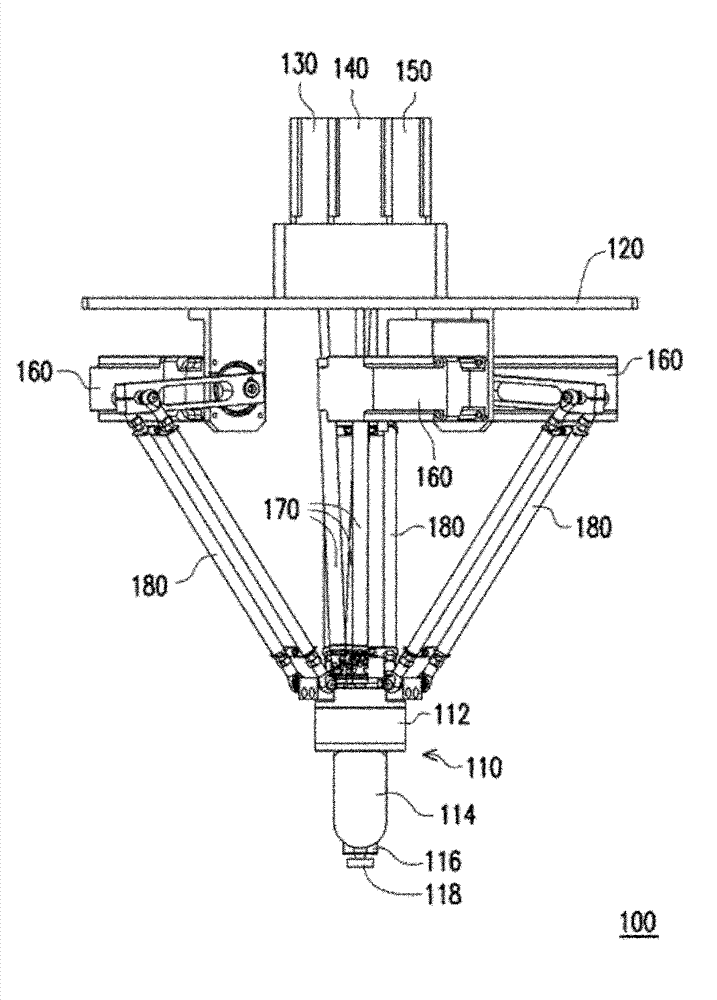

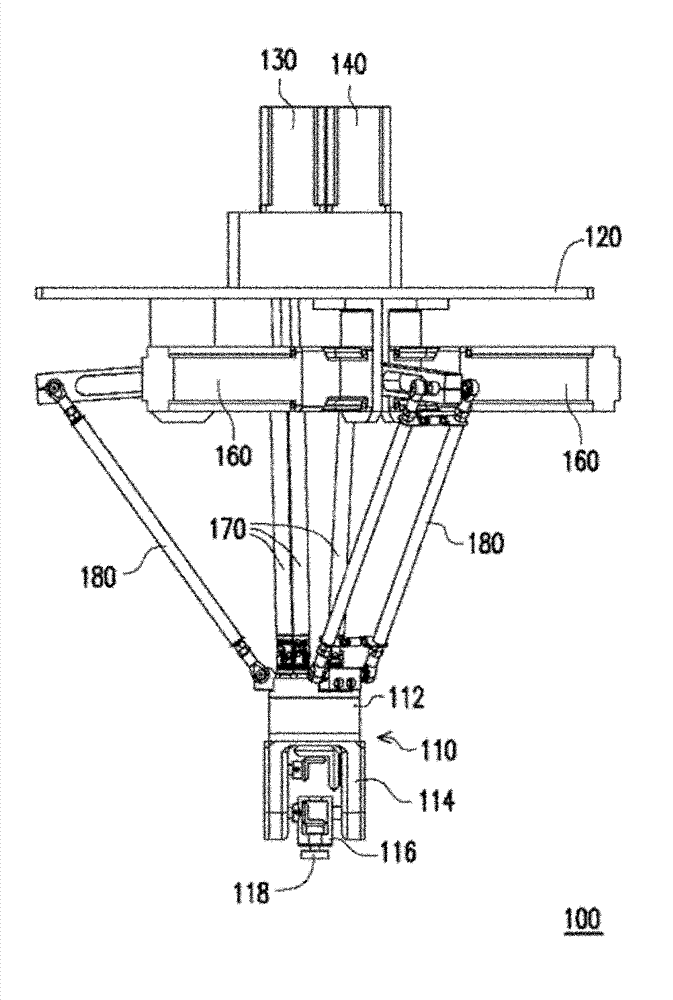

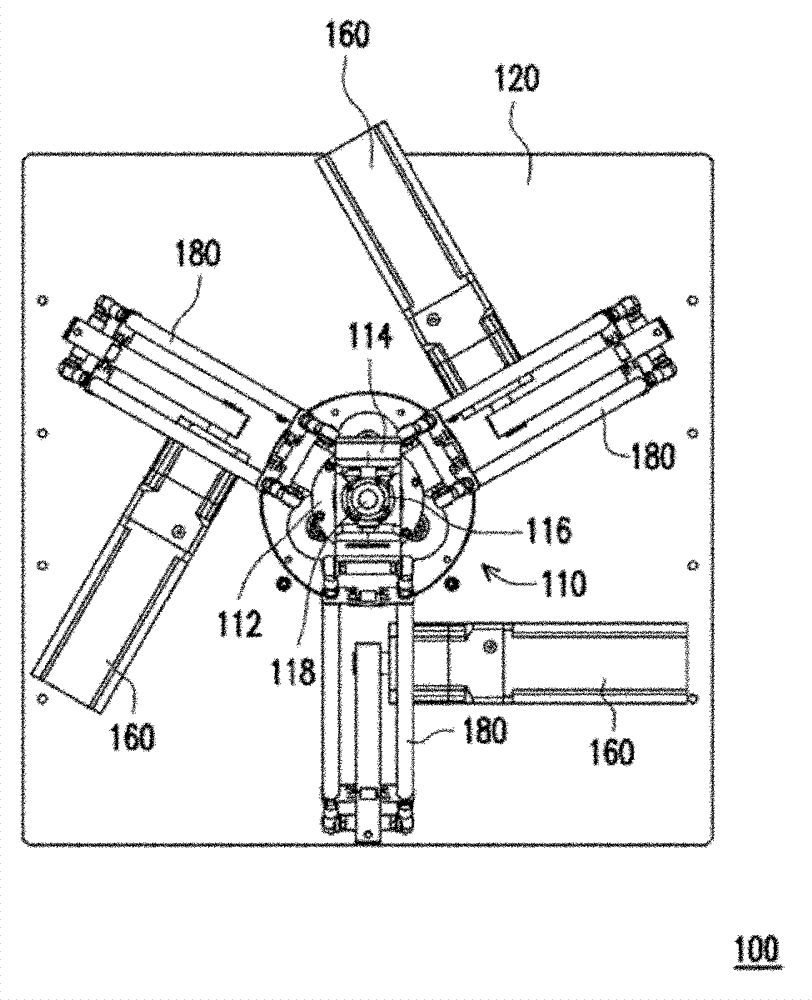

[0069] figure 1 It is a side view of a parallel robot according to an embodiment of the present invention. figure 2 for figure 1 A side view of the parallel robot from another perspective. image 3 for figure 1 The bottom view of the parallel robot. Please refer to Figure 1 to Figure 3 , the parallel robot 100 of this embodiment includes a wrist module 110, a base 120, a first actuating element 130, a second actuating element 140, a third actuating element 150 and a fourth actuating element 160 (shown as three ). The wrist module 110 includes a main body 112 , a first rotating part 114 , a second rotating part 116 and a third rotating part 118 . The first actuating element 130 , the second actuating element 140 and the third actuating element 150 are, for example, motors, and are used to drive the first rotating part 114 , the second rotating part 116 and the third rotating part 118 to rotate respectively. The fourth and third actuating elements 160 are also, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com