Rheology modifier

A technology of hydrophobic modification and branching agent, which is applied in thixotropic coatings, other chemical processes, dyeing polymer organic compound treatment, etc., to achieve the effect of improving viscosity balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

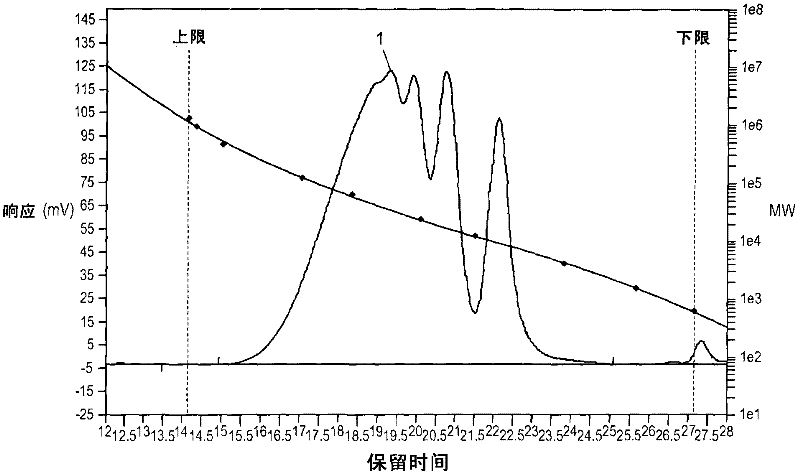

[0071] Example 1 -The CARBOWAX TM 8000 Polyethylene glycol (150 g) and toluene (360 g) were added to the vessel and dried by azeotropic distillation. The mixture was cooled to 90°C and Desmodur N3600 polyisocyanate (1.36 g) was added to the mixture. The mixture was stirred for 5 minutes, then dibutyltin dilaurate (0.21 g) was added. The mixture was stirred for 1 hour, then Desmodur H (4.15 g) was added. Stirring was continued for a further 1 hour, then cooled to 80°C. n-Decanol (3.91 g) was then added to the mixture and stirring was continued for a further 1 hour. The mixture was cooled to 60°C and the polymer was isolated by rotary evaporation. The ICI and KU viscosities were found to be 2.40 poise and 90.2 Krebs units, respectively. M measured by SEC w 79,000, M w / M n The polydispersity is equal to 3.1.

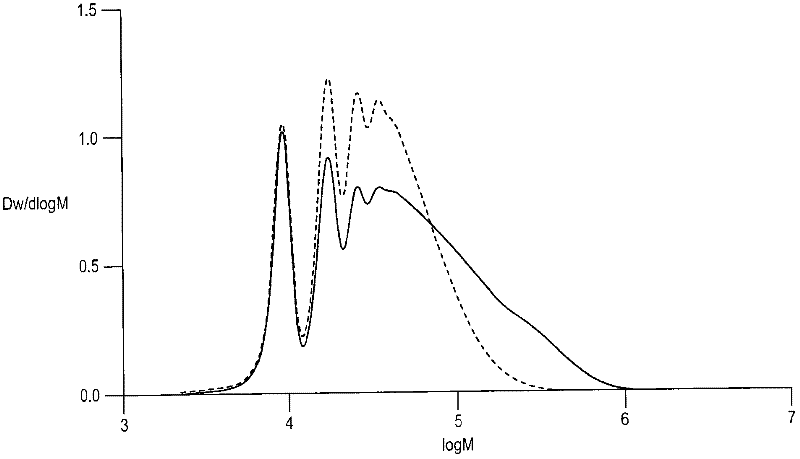

[0072] Although the types and amounts of raw materials used to prepare the polymers of Comparative Example 1 and Example 1 are the same, the products of Exampl...

Embodiment 2

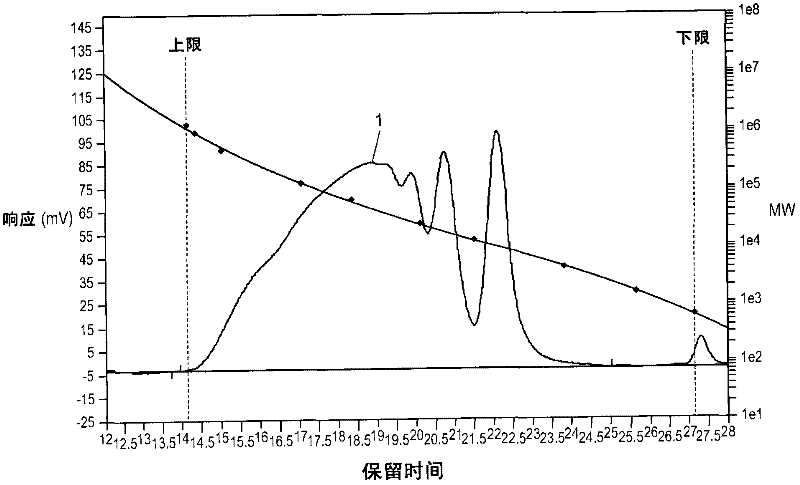

[0074] Will CARBOWAX TM 8000 A mixture of polyethylene glycol (150 g) and toluene (360 g) was charged to a vessel and dried by azeotropic distillation. The mixture was cooled to 90°C and Desmodur N3600 polyisocyanate (1.81 g) was added to the mixture. The mixture was stirred for 5 minutes, then dibutyltin dilaurate (0.21 g) was added. The mixture was stirred for 1 hour, then Desmodur H (3.94 g) was added. Stirring was continued for a further 1 hour, then cooled to 80°C. n-Decanol (3.91 g) was then added to the mixture and stirring was continued for a further 1 hour. The mixture was cooled to 60°C and the polymer was isolated by rotary evaporation. The ICI and KU viscosities were found to be 2.80 poise and 109.1 Krebs units, respectively. M measured by SEC w 124,000, M w / M n The polydispersity is equal to 4.4.

[0075] Likewise, compared with Comparative Example 2, the ICI / KU viscosity curve of Example 2 is better.

[0076] The samples prepared above were subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polydispersity | aaaaa | aaaaa |

| Mw | aaaaa | aaaaa |

| Polydispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com