Photosensitive drum and process cartridge

A photosensitive drum and photoreceptor technology, applied in the field of photosensitive drums, can solve problems such as affecting transmission efficiency, come out, and general products do not have suitable structures, and achieve the effect of ensuring smooth transmission and normal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

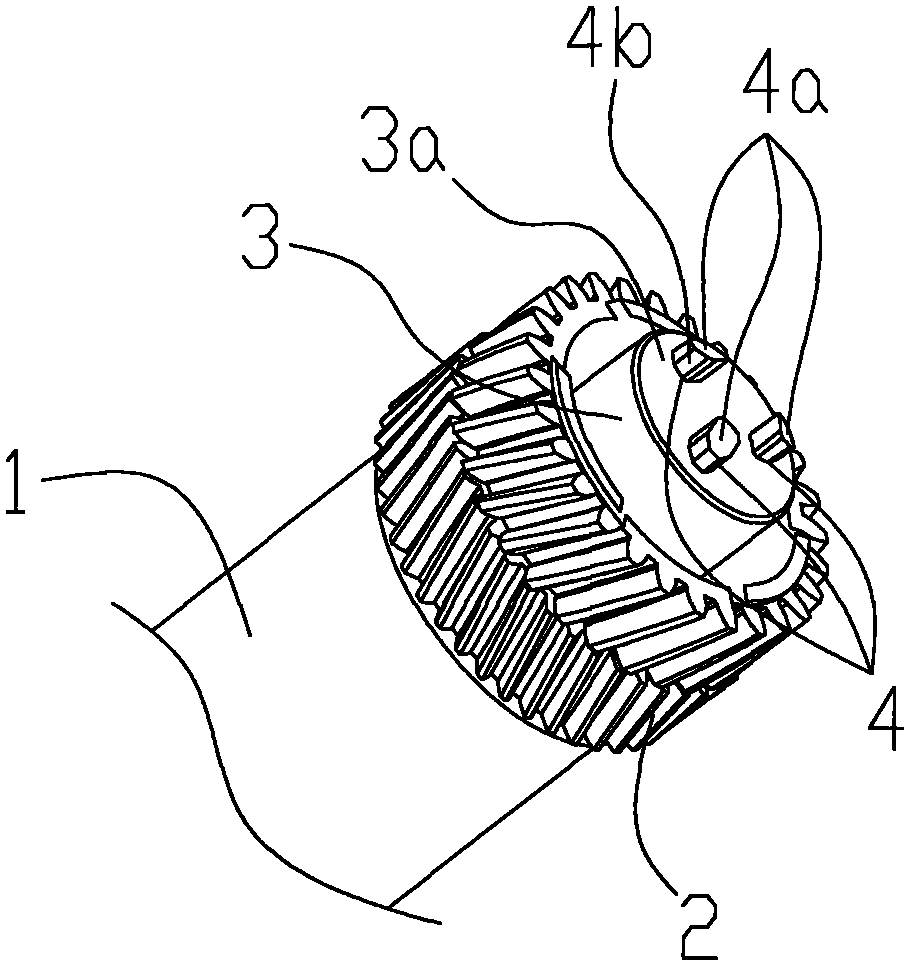

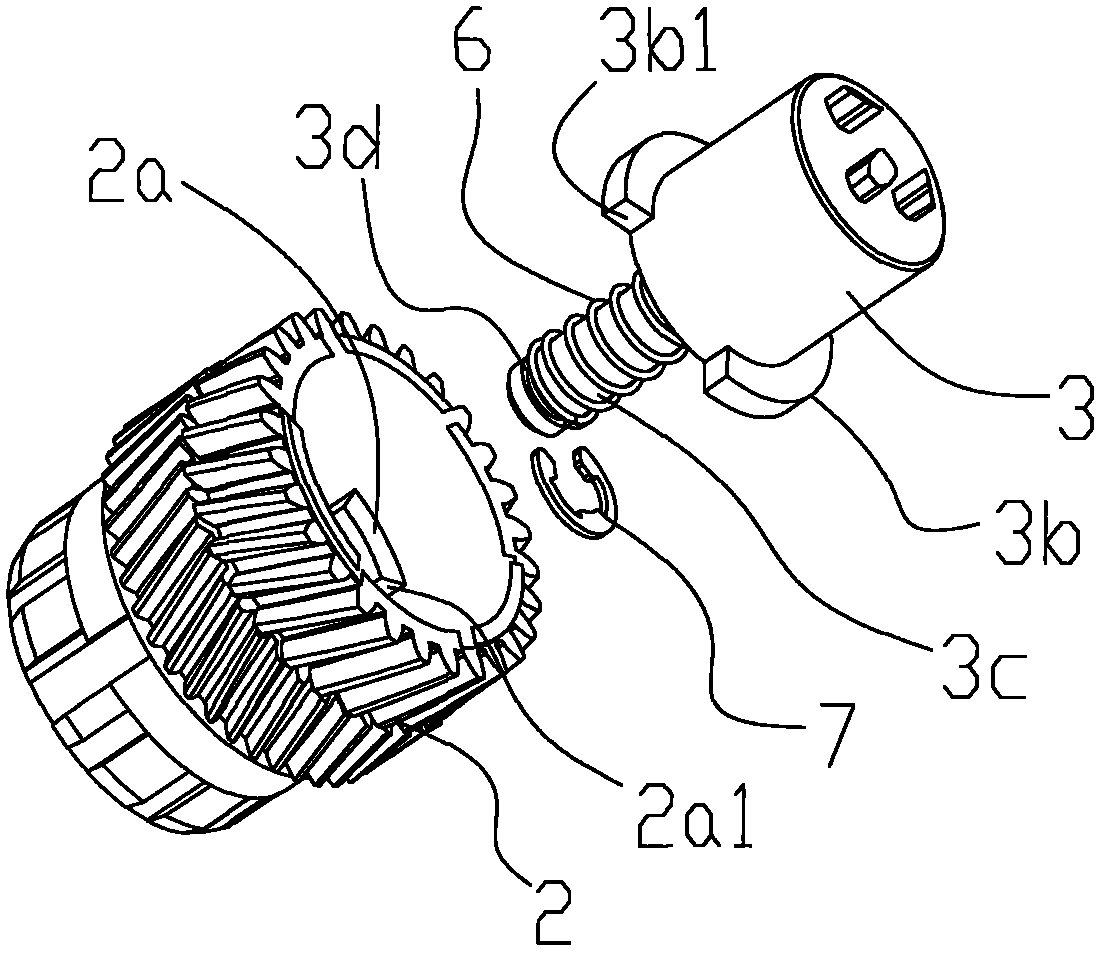

[0060] see figure 2 , image 3 and Figure 4 as shown, figure 2 is a perspective view of the drive head of the photosensitive drum according to the first embodiment of the present invention. image 3 is an exploded perspective view of the drive head at the end of the photoreceptor in the first embodiment of the present invention. Figure 4 is a sectional view of the drive head at the end of the photoreceptor in the first embodiment of the present invention. In this embodiment, the protrusion 4 is fixedly arranged on the end surface 3 a of the drum shaft 3 , and the drum shaft 3 is arranged on one end of the drum gear 2 so as to be telescopic along the axial direction of the photoreceptor 1 . Wherein, on the end of the drum shaft 3 corresponding to the drum gear 2, a power transmission part 3b and a guide column 3c are also provided, and on the drum gear 2, a power receiving part 2a and a receiving part cooperating with the power transmission part 3b are correspondingly p...

Embodiment 2

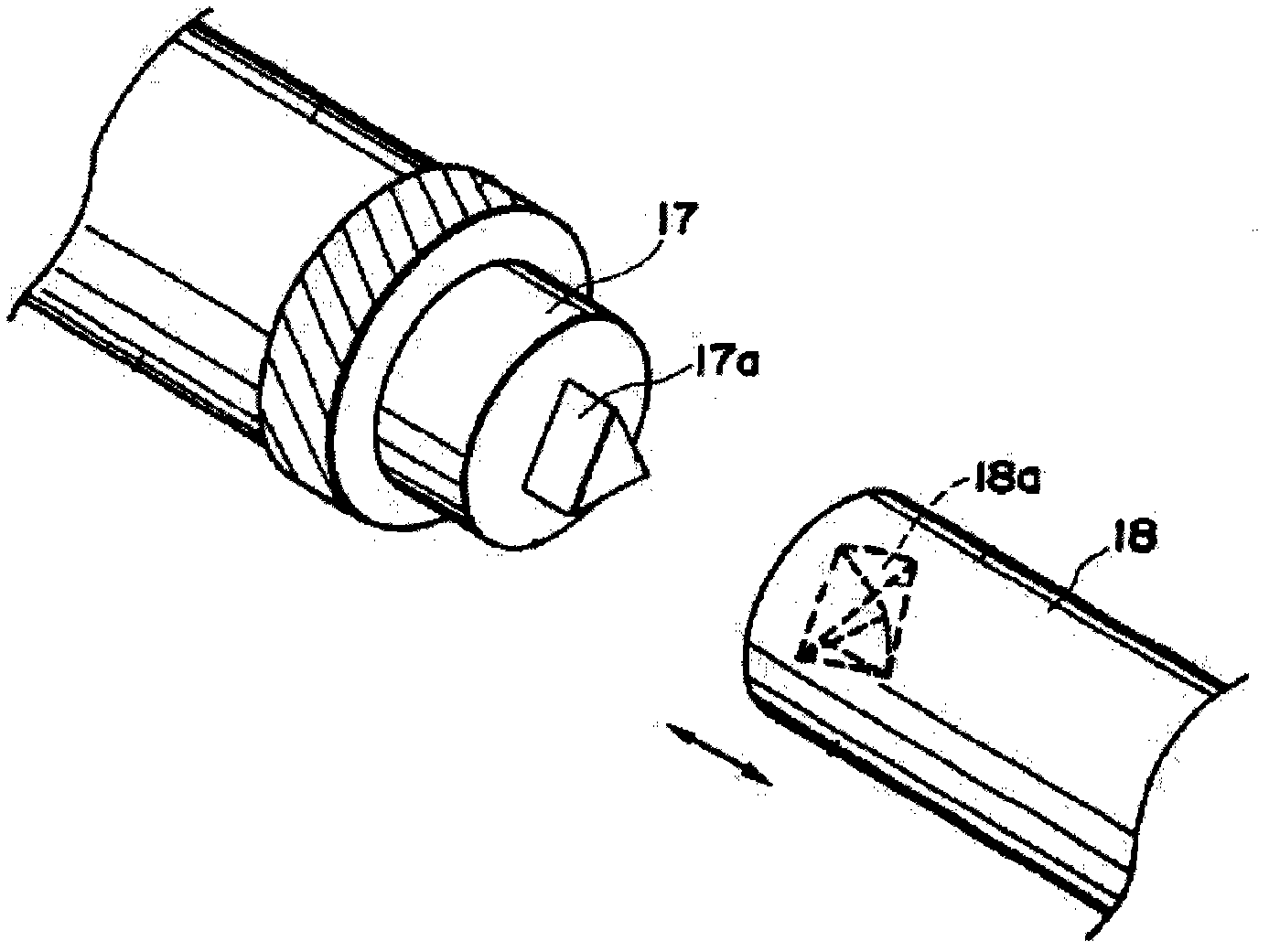

[0067] see Image 6 Shown is an exploded perspective view of the connection between the driving head of the photosensitive drum and the driving head of the image forming apparatus according to the second embodiment of the present invention. The photosensitive drum of this embodiment is basically the same as that of the first embodiment, the only difference being that in order to ensure the strength of the vertical projection 4 at the end of the photosensitive drum when it is driven between the drive head 20 of the image forming device, in this embodiment A boss 5 is also added between the three vertical projections 4 on the end face 3a of the photosensitive drum drum shaft 3 of the embodiment, and the three vertical projections 4 are arranged on the side walls of the boss 5, thereby ensuring The transmission efficiency and stability between the photosensitive drum and the image forming device.

Embodiment 3

[0069] see Figure 7 , Figure 8 as shown, Figure 7 is a perspective view of a drive head for a photosensitive drum according to a third embodiment of the present invention. Figure 8is a sectional view of the drive head at the end of the photoreceptor in the third embodiment of the present invention. The difference between the photosensitive drum of this embodiment and the first embodiment is that, in this embodiment, an opening groove 3f corresponding to the protrusion 4 is provided on the end face 3a of the drum shaft 3 of the photosensitive drum, so that the protrusion 4 is formed along the photosensitive drum. The length direction L of the body 1 is telescopically arranged in the opening groove 3 f to realize the expansion and contraction of the protrusion 4 along the length direction L of the photoreceptor 1 . The drum shaft 3 is fixedly arranged on the boss at the end of the drum gear 2 , and an accommodating space is formed between the end surface 2 d of the boss a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com