Reduced mass high speed doffer column with improved shaft preload

A technology for doffing and cotton columns, which is applied in the field of doffing columns, and can solve problems such as shaft bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

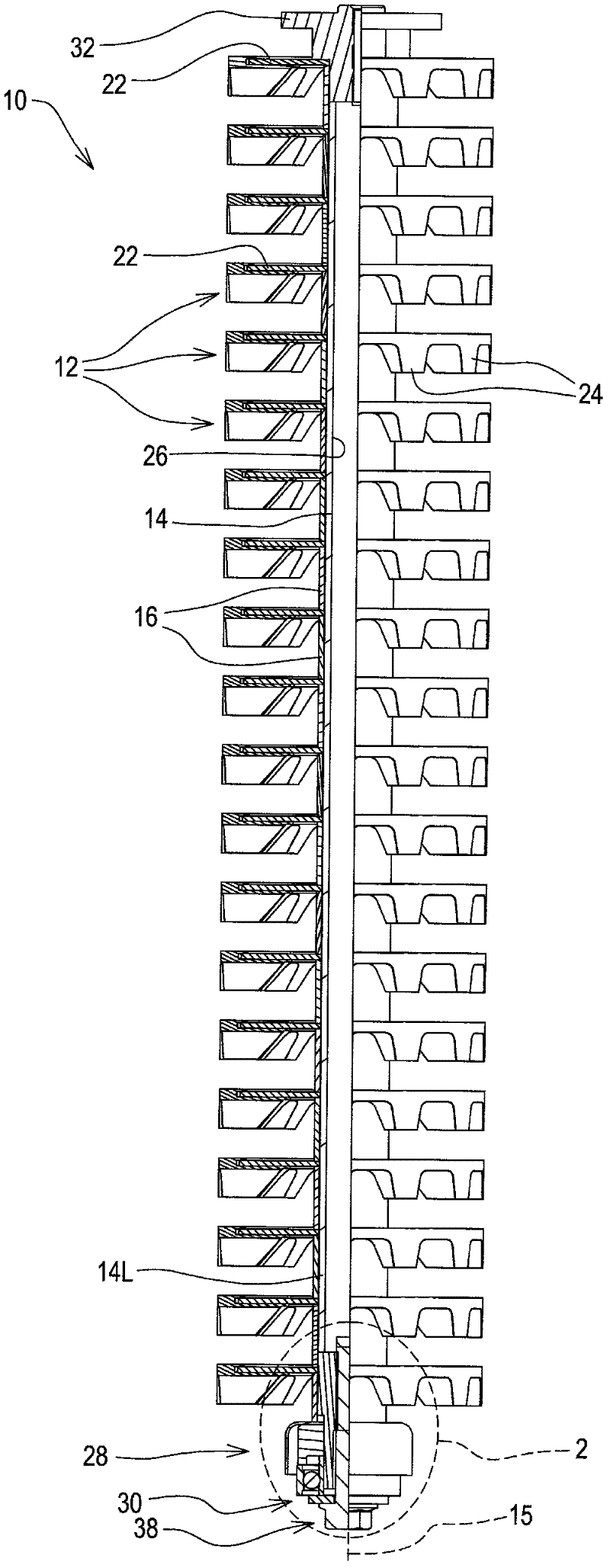

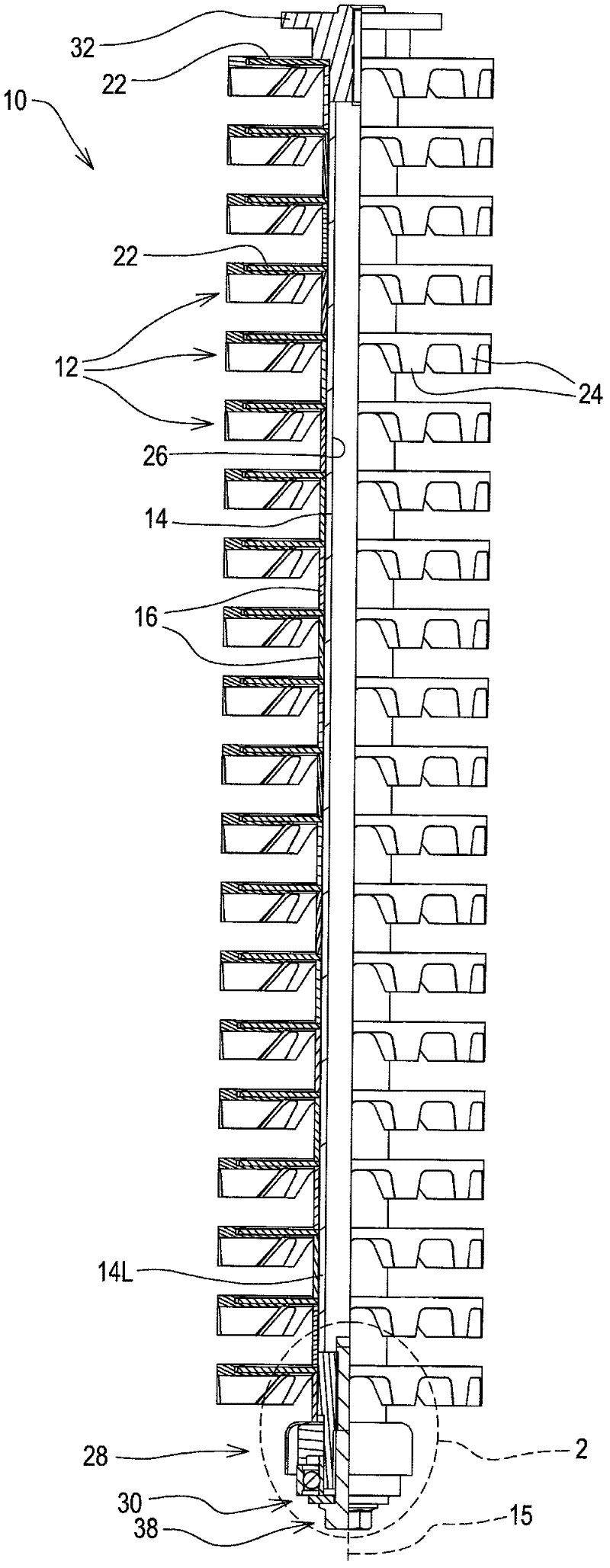

[0008] refer to figure 1 , which shows a doffer column assembly 10 for a harvester row unit of a conventional cotton picker. The doffer column structure 10 includes a plurality of doffers 12 supported on a vertical shaft 14 for rotation about an axis 15 . The doffers 12 are spaced vertically on the shaft 14 by spacers 16 . Alternatively, the spacers may be replaced by protruding hubs on the doffer 12 . Doffer 12 rotates with shaft 14 over rows of spindles and unwinds and removes cotton from the spindles in the rows.

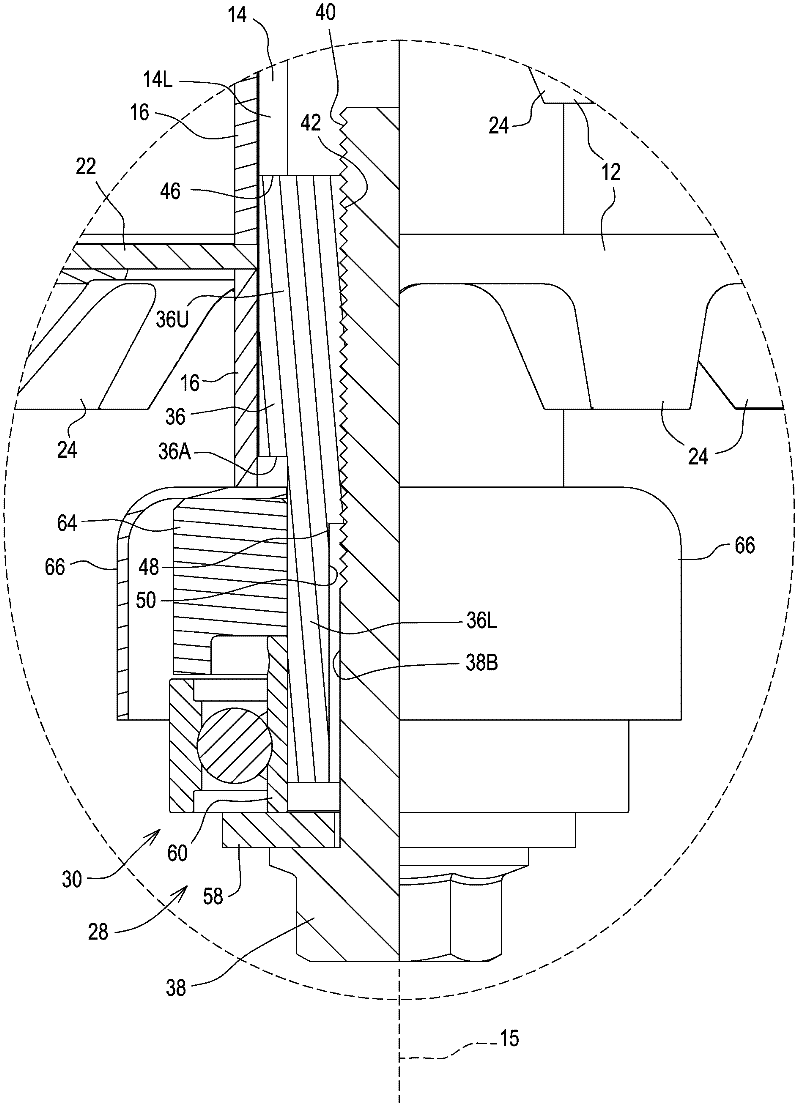

[0009] Each doffer 12 includes a generally horizontal circular metal disc or floor 22 supporting radially outwardly and downwardly oriented lugs 24 in a conventional manner. Located in the center of the base plate 22 is a circular hole 26 with a diameter slightly larger than that of the shaft 14 . Doffers 12 are slid into place on shaft 14 on which spacers 16 are inserted between adjacent doffers. Retention assembly 28 and bearing assembly 30 mount lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com