Wagon bogie

A technology for railway wagons and bogies, applied in bogies, railway car body parts, transportation and packaging, etc., can solve problems such as rhomboid deformation, low critical speed, poor stability, etc., to improve anti-diamond stiffness, improve adaptability, The effect of high critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

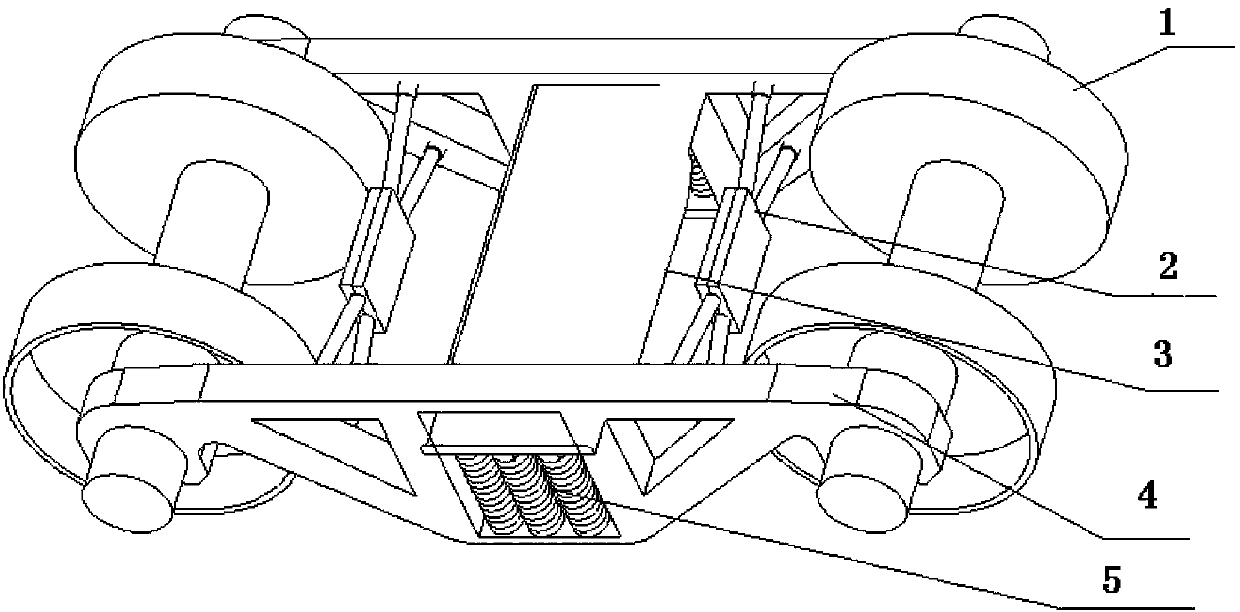

[0015] combine Figure 1~3 , The bogie of the present invention mainly comprises a wheel set device 1, a bolster 2, a side frame 4, a cross support device 3 and a damping device 5. Wherein the damping device 5 is a friction shock absorber, which is made up of a combination wedge and a pillow spring device.

[0016] In order to improve the anti-diamond stiffness of the three-piece bogie, the cross support device 2 is arranged symmetrically on both sides of the bolster 3, wherein the center of gravity of the cross support device 2 and the center of gravity of the two side frames 4 are on the same plane.

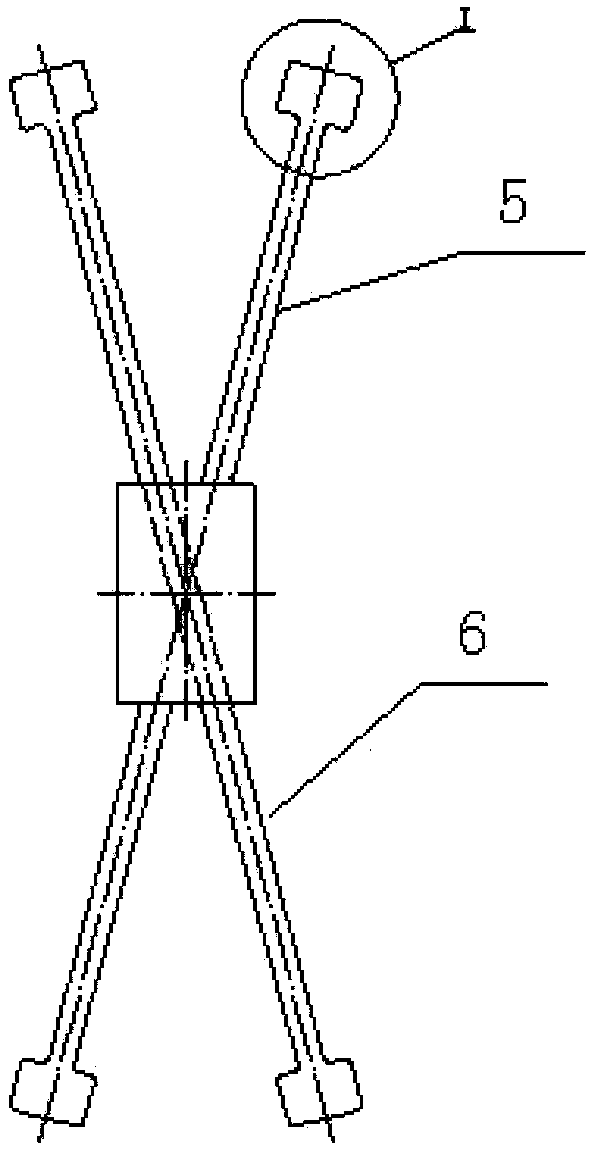

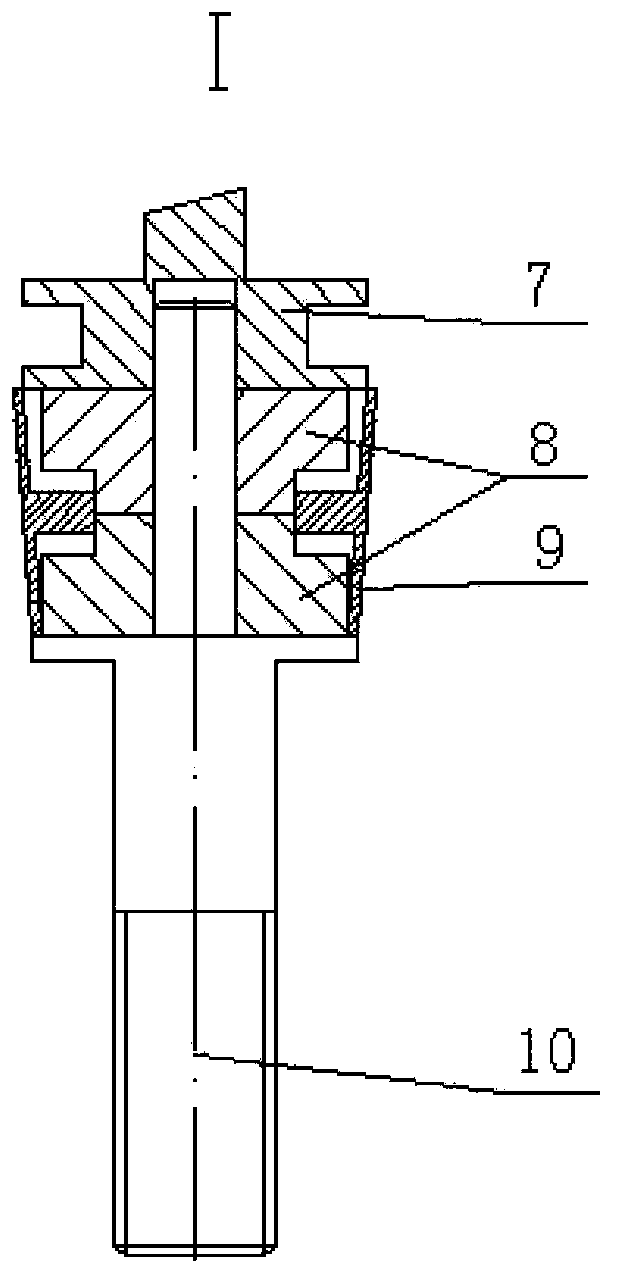

[0017] like figure 2 , Two groups of cross support devices are made up of an elastic joint I and two cross bars 5,6. Bar 6 directly passes through the intersecting hole reserved by bar 5 at the intersection position, and bar 5 and bar 6 are connected by elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com