Railway wagon bogie and side frame cross bar mechanism connection method and railway wagon bogie and side frame cross bar mechanism connection device

A technology for railway wagons and coupling devices, which is applied to bogies, railway car body parts, transportation and packaging, etc., to achieve the effects of reducing dynamic forces, avoiding mutual rotation, and improving structural fatigue reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

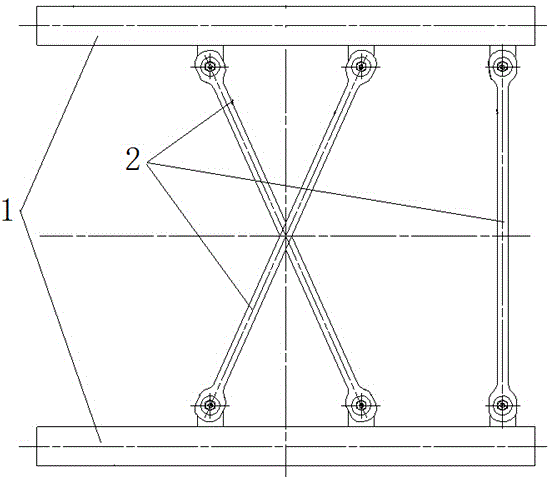

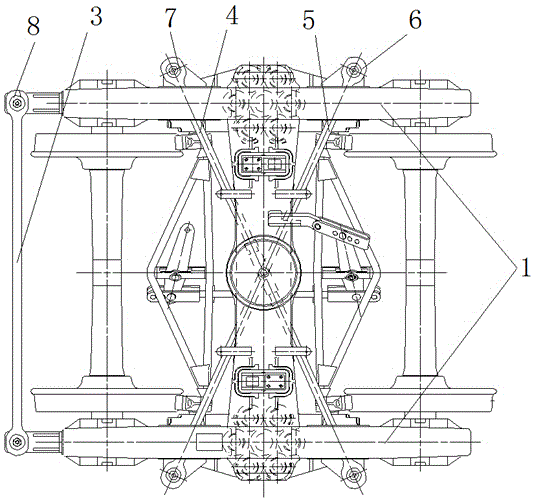

[0041] by attaching figure 1 and 2 It can be seen that the present invention relates to a railway freight car bogie and a side frame crossbar mechanism, which includes two side frames 1, and is provided between the two side frames 1 to prevent relative movement between the two side frames in the horizontal plane. The connecting rod 2 is characterized in that the connecting rod used to prevent the relative movement between the two side frames in the horizontal plane is a 5-bar linkage.

[0042] The 5-bar linkage mechanism includes three links and two bars formed by two side frames, and the two sides frames are connected with the two ends of the three connecting rods to form a five-bar link mechanism in the horizontal plane.

[0043] Described 5 connecting rods are provided with three support bases 6, 7 and 8 on each side frame, and the support bases are respectively located at the outer side and the end of the side frame according to the structural size characteristics. A co...

Embodiment 2

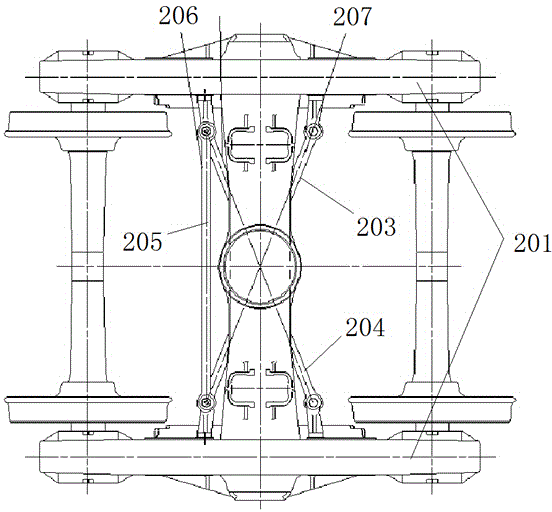

[0046] The structure of the second embodiment is the same as the basic principle of the first embodiment, except that the arrangement of the three connecting rods is different, as shown in the attached image 3 shown. A railway freight car bogie and side frame cross bar mechanism, including two side frames 201, and a connecting rod for preventing relative movement between the two side frames in the horizontal plane is arranged between the two side frames 201, and its characteristic is that , the connecting rod used to prevent the relative movement between the two side frames in the horizontal plane is a 5-bar linkage mechanism.

[0047] The 5-bar linkage mechanism includes three links and two bars formed by two side frames, and the two sides frames are connected with the two ends of the three connecting rods to form a five-bar link mechanism in the horizontal plane.

[0048] The five connecting rods are provided with two supporting seats 206 and 207 on each side frame, and th...

Embodiment 3

[0052] The structure of the third embodiment is the same as the basic principle of the first embodiment, but the arrangement of the three connecting rods is different, as shown in the attached Figure 4 As shown, a railway freight car bogie and side frame cross bar mechanism includes two side frames 301, and a connecting rod for preventing relative movement between the two side frames in the horizontal plane is arranged between the two side frames. The feature is that the connecting rod used to prevent the relative movement between the two side frames in the horizontal plane is a 5-bar linkage mechanism.

[0053] The 5-bar linkage mechanism includes three links and two bars formed by two side frames, and the two sides frames are connected with the two ends of the three connecting rods to form a five-bar link mechanism in the horizontal plane.

[0054] The five connecting rods are provided with three supporting seats 306, 307 and 308 on each side frame, and the supporting seats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com