Continuous sugar soaking machine

A technology of dipping and drenching sugar, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of increased production cost, accelerated deterioration of sugar liquid, and low productivity, so as to prolong the service life and reduce labor The effect of high strength and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

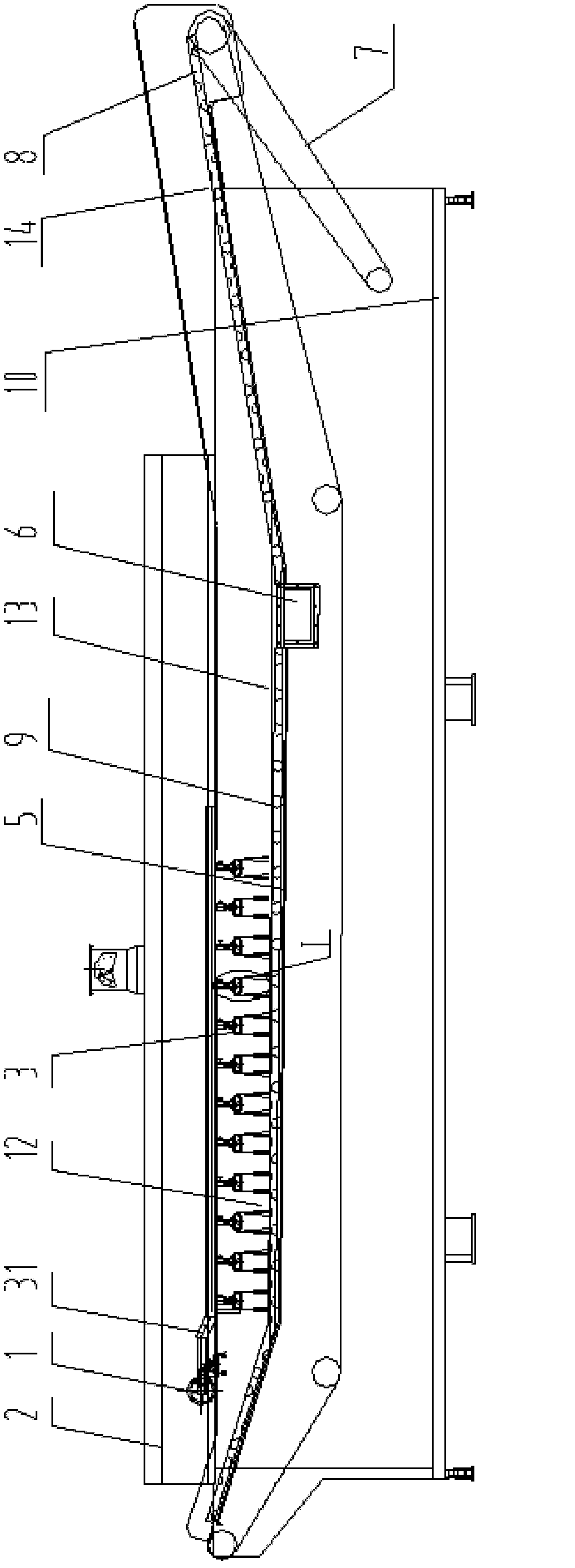

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

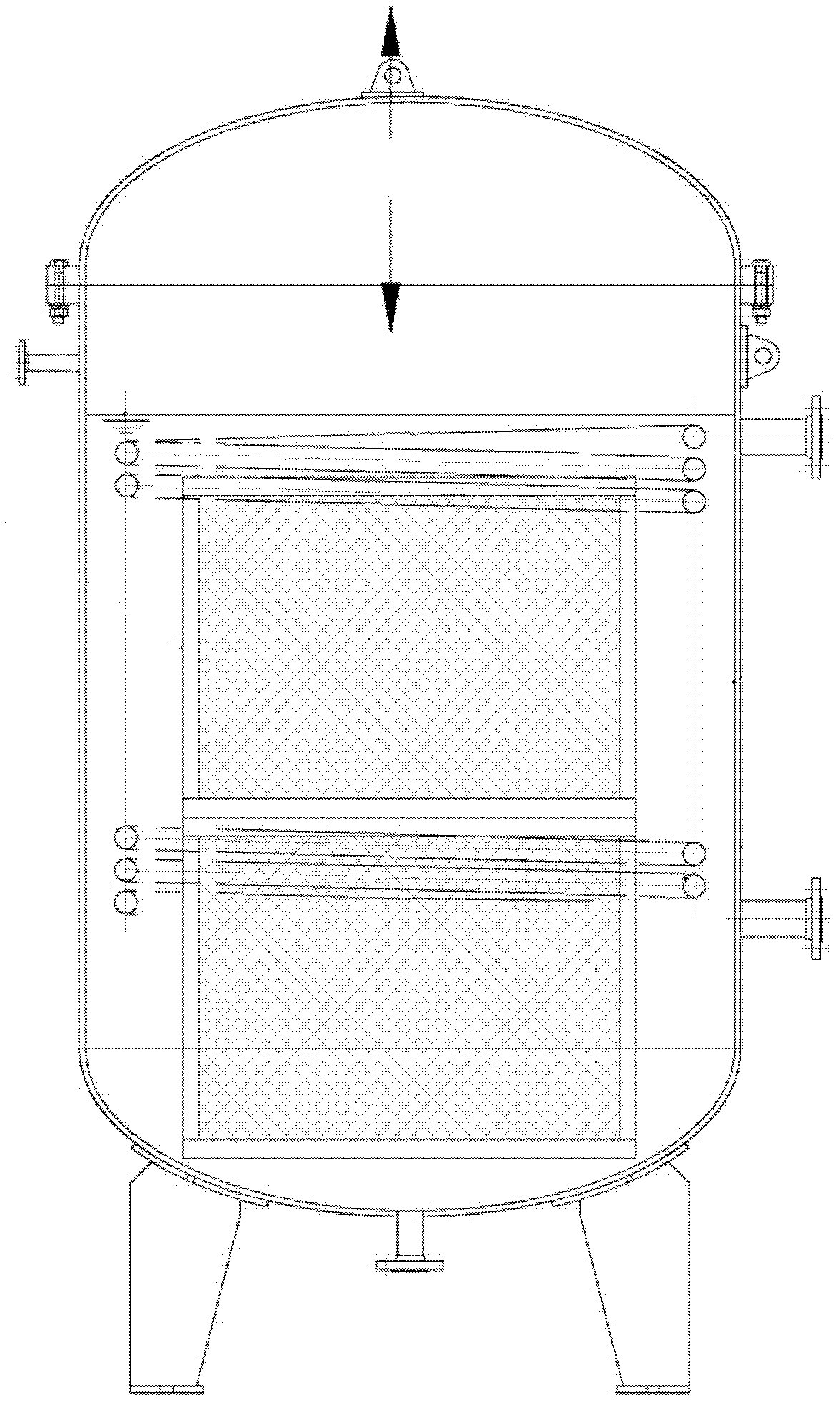

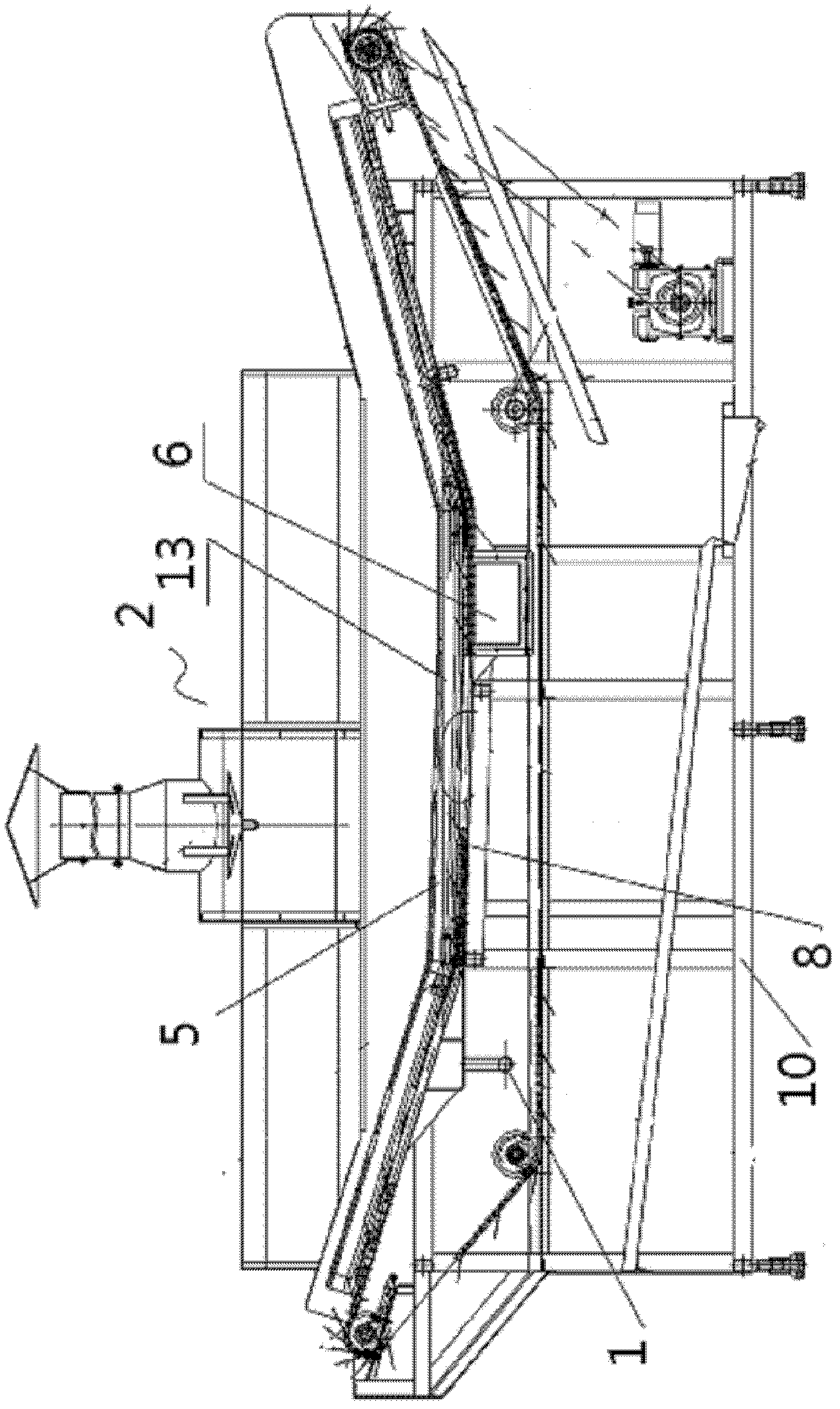

[0038] see image 3 , image 3 It is a structural schematic diagram of a sugar dipping machine according to an embodiment of the present invention. The sugar dipping machine of the present invention comprises a bracket 10, a pot body 5, a feeding device 8 and a spray device 3, wherein the pot body 5 is fixed on the upper part of the bracket 10 for supporting the pot body 5, and the feeding device 8 is arranged on the pot body In 5, for realizing the continuous sugar dipping of the material 9, the gas collecting hood 2 is arranged above the pot body 5, and is used to collect the water vapor generated in the sugar dipping pot body 5, and discharge it to the atmosphere; The conveying device 8 is arranged on the bottom of the pot body 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com